m Drivers &Mechanics TEN SHILLINGS WEEKLY is paid for the

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send ws an account of any special incident of your work or exfierience. If suitable, we will edit your notes, supply a sketch when required, and pay you for everything published. Mention your empiover's name, in confidence, as evidence of good faith. Address to The Editor, THE COMMERCIAL MOTOR, Rosebery Avenue, London, E.G.

Light Up Your Lamps At 9.19 on Thursday,9.19 on Friday ; 9.19 OD Saturday; 9.19 on Monday ; 9.18 on Tuesday ; 9,18 on Wednesday.

What to Use instead of a Pit.

[1528] "H.T." (Queen's Park) writes :—"It sometimes happens that a driver has to perform a repair to a machine which renders necessary the use of a. pit, and if no pit is handy it becomes-a very awkward and difficult job. Some time ago the van which I

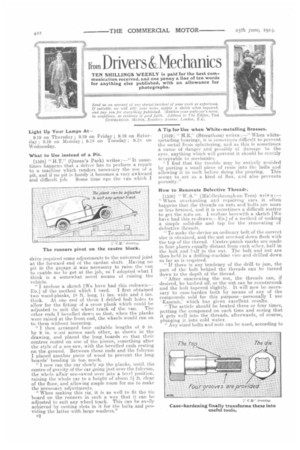

drive required some adjustments to the universal joint at the forward end of the cardan shaft. Having no pit in the garage it was necessary to raise the van to enable me to get at the job, so I adopted what I think is a somewhat novel means of raising the vehicle.

"I enclose a sketch [We have had this redrawn.— En.] of the method which I used. I first obtained two wood-planks, 1B ft. long, 11 ins, wide and 4 ins. thick. At one end of these I drilled bolt holes to allow for the fitting of a cross plank which could be adjusted to suit the wheel track of the van. The other ends I bevelled down so that, when the planks were raised at the front end, the wheels would run on to them without bouncing.

" I then arranged four suitable lengths of 9 in. by 9 in. wood across each other, as shown in the -drawing, and placed the long .boards so that their centres rested on one of the pieces, something after the style of a see-saw, with the bevelled ends resting on the ground. Between these ends and the fulcrum I placed another ,piece of wood to prevent the long boards' bending in too much.

" I now ran the car slowly up the planks, until. the -centre of gravity of the car going just over the fulcrum, the whole affair see-sawed over into a level position, raising the whole, car to a height of about 3 ft. clear of the floor, and allowing ample room for me to make the necessary adjustments.

" When making this rig, it is as well to fit the tie board on the runners in such a way that it can he adjusted to suit any wheel track, This can he easily achieved by cutting slots in it for the bolts and providing the latter with large washers."

F2 A Tip for Use when White-metalling Brasses.

(1629J " H.R.." (Streatham) writes :—" When whitemetalling bearings, it is sometimes difficult to prevent the metal from spluttering, and as this is sometimes a cause of danger and possibly of damage to the eyes, anything which will prevent it should be readily acceptable to mechanics.

"I find that the trouble may be entirely avoided by putting a small piece of resin into the ladle and allowing it to melt before doing the pouring. This seems to act as a kind of flax, and also prevent& porosity."

How to Renovate Defective Threadr.

11530.1 " W. S." (Mit'allesbrough-on-Tees) wri'l-s:— " When overhauling and repairing cars it often happens that the threads on nuts and bolts are more or less bruised, and it is sometimes a difficult matter to get the nuts on. I enclose herewith a sketch [We have had this redrawn.liod of a method of making a simple solid-die and tap for the renovating of defective threads.

"To make the device an ordinary bolt of the correct size is oblained, and the. nut screwed down flush with the top of the thread. Centre-punch marks are made in four places equally distant from each other, half in the bolt and half in the nut. The bolt and nut are then held in a drilling-machine vice and drilled down so far as is required.

"If there is any tendency of the drill to jam, the part of the bolt behind the threads can be turned down to the depth of the thread. " After unscrewing the nut, the threads can, if desired, be bathed off, or the nut can be countersunk and the bolt tapered slightly. It will now be necessary to case-harden both by means of any of the compounds sold for this purpose—personally I use Kase/lit,' which has given excellent results.

"The article should be heated three or four times, putting the compound on each time and seeing that it gets well into the threads, afterwards, of course, plunging it into cold water.

"Any sized bolts and nuts can be used, according to

the various individual requirements ; personally I have used a set for some time, and have found them absolutely indispensable, and as they are easy to make and cheap, it is quite easy to replace them, and there is not the difficulty of fitting them to take the die-stock and spanner as is the case when they are made out of east steel. While using them I have found that the best result is obtained by using ratchet spanners."

A Simple but Efficient Valve-grinder.

The sender of the followinii communication has been awarded the io.1. prize this week.

[1531] "J.C.11." (Bristol) writesi—'. The grinding-in of valves is an important item in the upkeep of a commercial vehicle if good results are to be obtained from the engine. At the same time, the job is rather a tiresome ono, and if the screwdriver method is used, it is also somewhat lengthy. There are several types of tools on the market. by which the valve is reciprocated while the handle of the tool is kept constantly turning m the same direction. The cost of these, however, almost prohibits their use by an

ordinary driver, although they may quite satisfactorily be used as part at the equipment of a garage.

" About two years ago I made a tool, using a, very old principle, but having the giaat advantage of being made out of odds and ends. The old principle to which I refer is that of the Archimedean drill. I enclose a sketch of the tool —.We have had this reOrawn.—En.j—ewhich shows how easily it, can be made.

" The centre shaft is a piece of steel 12 in. square and about '24 ins, long. This is heated in the centre and given two-and-a-quarter complete turns, one mid being held in a vice for this purpose, while the other is turned, by any suitable means. It is afterwards trued by re-heating and hammering on a wood block, using a wood mallet to prevent any damage to the corners, which should be sharp.

In order that the twist shall be regular, the heating must, of course, be uniform for the whole of the distance for which the turns are fequired. About ins, at one end should be left untwisted, and this end must be bevelled off in a similar manner to the and of a screwdriver. Enough should be left unturned at the other end to allow for fitting a. file handle, which is slipped over the end after filing or turning the shaft round.

" It will be found more convenient, while using the tool, if the file handle is put on in the reverse direction, and if the tool is to he much used, thc file handle should be fitted with a piece of brass tube to act as a bush, but if the tool only be used occasionally, the plain wood may do. Washers are secured at each end of the handle, and the top end of the shaft is riveted over.

"At the other end of the rod a pin or collar should be placed just above the start of the twist, to avoid jamming of the sleeve at the bottom of its stroke. The sleeve itself is made front a piece of tubing of such size as will pass freely over the shaft and hold the, two intarnally-squared ends which are fixed into it by any suitable method. Soldering and pinning are quite sufficient, tut if requited they can be screwed,

although in this case they may have a tendency to unscrew while the tool is in use, unless also pinned. Another method of fitting these ends is to braze them in, which mak-es quite a good job.

" The total length of the sleeve. is about the same as one complete twist of the shaft. Care should be taken that the position of the squared holes is corieci before finally fitting the ends in position. The shaft must be caeefully cleaned to ease the working of the sieeve. The latter can also be filled with thick grease to provide lubrication.

" The moving up and down of this sleeve will now cause the shaft to reciprocate, the handle meanwhile being held iii the other hand. This device will be found very haudy.where the ordinary brace would be in the way of piping, etc., and it is also much easier to use than the brace when the engine is placed somewhat high in the frame."

Removing Dents holm Petrol or Oil Tanks.

Lio.3211 (' KN." (Tonbeidge) wrieel—" Occasionally petrol tanks, especially those on the dashboard or at the rear old of commercial vehicles, become dented or kinked, and they then present a very untidy appearance. To remove a kink, it is usually considered necessary to cut a large hole in the tank, and to hammer the kink out from the inside, afterwards sol. tiering a patch over the hole.

" A simple method of removing these indentatiora which I have applied, and which I have found vela successful, besides being easy to carry out, is to procure a bar of steel about in. or i" in. in diameter, and 2 ft. long, and saw this up the centre for about 2 ins. at one end. The sawn end is heated in the blowlamp or forge until red-hot; it is then fixed in a vice, and opened out into the shape of a ' T ' by the aid of a hammer and chisel.

"At the other end of the bar is drilled a in, hole, and through this is passed a length of wire brakecable to form a sling, the ends of the cable being fastened together. The dent in the tank must now be well scraped and the. tank itself removed from the chassis. The dent is then well tinned, and the opened-out end of the bar is heated, tinned, and soldered to it.

" The tank is next suspencictel on a beam by the sling on the bat, and at such a height that pressure can be applied on the tank by means of the hands. Now, by gently but firmly pressing the tank down, it will be found that the dents can be readily removed. 'If the tank is small or very thin, it is easier to grip the bar in the vice after soldering it to the tank, and then to pull the latter towards you, instead of suspending it from a beam and pressing it down. With very small kinks this method is not necessary, as they car), lie quite easily cleaned and filled up with solder, whieit is afterwards painted over.