Third axle fills the gap

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

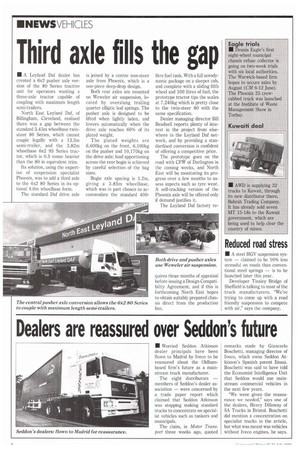

• A Leyland Daf dealer has created a 6x2 pusher axle version of the 80 Series tractive unit for operators wanting a three-axle tractor capable of coupling with maximum length semi-trailers.

North East Leyland Daf, of Billingham, Cleveland, realised there was a gap between the standard 3.45m wheelbase twinsteer 80 Series, which cannot couple legally with a 13.5m semi-trailer, and the 3.82m wheelbase 6x2 95 Series tractor, which is 0.5 tonne heavier than the 80 in equivalent trim.

Its solution, using the expertise of suspension specialist Phoenix, was to add a third axle to the 4x2 80 Series in its optional 4.0rn wheelbase form.

The standard Daf drive axle is joined by a centre non-steer axle from Phoenix, which is a one-piece deep-drop design.

Both rear axles are mounted on Weweler air suspension, located by overslung trailing quarter elliptic leaf springs. The pusher axle is designed to be lifted when lightly laden, and lowers automatically when the drive axle reaches 60% of its plated weight.

The plated weights are 6,600kg on the front, 6,100kg on the pusher and 10,170kg on the drive axle; load apportioning across the rear bogie is achieved by careful selection of the bag sizes.

Bogie axle spacing is 1.2m, giving a 3.85m wheelbase, which was in part chosen to accommodate the standard 400 litre fuel tank, With a full aerodynamic package on a sleeper cab, and complete with a sliding fifth wheel and 100 litres of fuel, the prototype tractor tips the scales at 7,240kg which is pretty dose to the twin-steer 80 with the same specification.

Dealer managing director Bill Beadnell reports plenty of interest in the project from elsewhere in the Leyland Daf network, and by providing a standardised conversion is confident of offering a competitive price.

The prototype goes on the road with CFW of Darlington in the coming weeks, and North East will be monitoring its progress over a few months to assess aspects such as tyre wear. A self-tracking version of the Phoenix axle will be offered only if demand justifies it.

The Leyland Daf factory re quires three months of appraisal before issuing a Design Compatibility Agreement, and if this is forthcoming North East hopes to obtain suitably prepared chassis direct from the production line.