Powered Steering Control

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

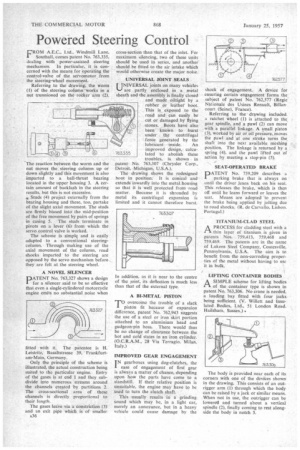

FROM A.E.C., Ltd., Windmill Lane, Southall, comes patent No. 763,335, dealing with power-assisted steering mechanism. In particular, it is concerned with the means for operating the control-valve of the servomotor from the steering-wheel movement.

Referring to the drawing, the worm (1) of the steering column works in a nut trunnioned on the rocker arm (2),

The reaction between the worm and the nut moves the steering column up or down slightly and this movement is also imparted to a ball-thrust bearing located in the upper housing 3. A certain amount of backlash in the steering results, but this is not excessive.

* Studs (4) project externally from the bearing housing and these, too, partake of the slight axial movement. The studs are firmly biased into the mid-position of the free movement by pairs of springs in casing 5. The studs terminate in pivots on a lever (6) from which the servo control valve is worked.

. The scheme is simple and is easily adapted to a conventional steeringcolumn. Through making use of the axial movement of the column, road shocks imparted to the steering are opposed by the servo mechanism before they are felt at the steering wheel.

A NOVEL SILENCER

PATENT No. 763,327 shows a design for a silencer said to be so effective that even a single-cylindered motorcycle engine emits no substantial noise when fitted with it. The patentee is H. Leistritz, Basaltstrasse 39, Frankfurtam-Main, Germany.

Only the principle of the scheme is illustrated, the actual construction being suited to the particular engine. Entry of the gases is at end 1 and they subdivide into numerous streams around the channels created by partitions 2. The cross-sectional area of these channels is directly proportional to their length.

The gases leave via a constriction (3) and an exit pipe which is of smaller A36 cross-section than that of the inlet. For maximum silencing, two of these units should be used in series, and another should be fitted to the air intake which would otherwise create the major noise.

UNIVERSAL JOINT SEALS

UNIVERSAL joints on many vehicles are partly enclosed in a metal sheath and the assembly is finally closed

and made oiltight by a rubber or leather boot. This is exposed to the road and can easily be cut or damaged by flying ' stones. Boots have also

▪ •been known to burst

under the centrifugal force generated by the lubricant inside. An improved design, calculated to abolish these troubles, is shown in patent No. 763,307 (Chrysler Corp., Detroit, Michigan, U.S.A.).

The drawing shows the redesigned hoot in position. It is conical and extends inwardly into the metal housing so that it is well protected from road matter. Because it is shrouded by metal its centrifugal expansion is limited and it cannot therefore burst. 763335 In addition, as it is near to the centre of the joint, its deflection is much less than that of the external type.

A BI-METAL PISTON

Povercome the trouble of a slack piston fit because of expansion difference, patent No. 762,943 suggests the use of a steel or iron skirt portion attached to an aluminium head and gudgeon-pin boss. There would thus be no change of clearance between the hot and cold states in an iron cylinder. (0.C.R.A.M., 28 Via Terragio, Milan, Italy.)

IMPROVED GEAR ENGAGEMENT

INgearboxes using dog-clutches, the ease of engagement of first gear is always a matter of chance, depending upon how the parts have come to a standstill. If their relative position is unsuitable, the engine may have to he used to turn the clutch shaft.

This usually results in a grinding sound which may be, in a light car, merely an annoyance, but in a heavy vehicle could cause damage by the

shock of engagemeni A device for ensuring certain engagement forms the subject of patent No. 762,577 (Regie Nationale des Usines Renault, Billancourt (Seine), France).

Referring to the drawing included. a ratchet wheel (I) is attached to the, gear spindle, and a pawl (2) can move with a parallel linkage. A small piston (3), worked by air or oil pressure, moves the pawl and at one stroke turns the shaft into the next available meshing position. The linkage is returned by a spring (4), and the pawl lifted out of action by meeting a stop-pin (5).

SEAT-OPERATED BRAKE

PATENT No. 759,209 describes a parking brake that is always on until the driver Jeans back on his seat. This releases the brake, which is then off until he leans forward or leaves the seat. Means are adopted to prevent the brake being applied by jolting due to road shocks. (R. de Carvallo, Lisbon. Portugal.)

TITANIUM-CLAD STEEL

APROCESS for cladding steel with a thin layer of titanium is given in patents Nos. 759,413, 759,468 and 759,469. The patents are in the name of Lukens Steel Company, Coatesville, Pennsylvania, U.S.A. The aim is to benefit from the non-corroding properties of the metal without having to use it in bulk.

LIFTING CONTAINER BODIES A SIMPLE scheme for lifting bodies of the container type is shown in patent No. 763,306. No crane is needed, a loading bay fitted with four jacks being sufficient. (V. Willett and Insulated Bodies, Ltd., 51 London RoadHailsham, Sussex.)

The body is provided near each of its corners with one of the devices shown in the drawing. This consists of an outrigger arm (1) through which the body can be raised by a jack or similar means. When not in use, the outrigger can be lowered and turned about a vertical spindle (2), finally coming to rest alongside the body in notch 3.