The Conveyance of ACIDS BY ROAD.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

Thousands of Tons Weekly Transported and Stored in Carboys. How Rubber-lined Tanks May Revolutionize Present Methods. Problems to be Overcome.

DESPITE the fact that many thousands of tons of acids, such as hydrochloric and sulphuric, are employed each week as basic materials, over 90 per cent., in the ease of hydrochloric acid, is still -being delivered in carboys, whieh are glass bottles, large when considered as such, but comparatively small when viewed as a medium for conveying huge quantities of liquids. Twenty carboys with their bulky protecting hampers weigh some 036 lb., although their total capacity is only a ton; also, each carboy occupies a floor space of 6Asq. ft.

Under the present system, this type of container is also' temporarily employed to store acid for the consumer between weekly deliveries, thus fully doubling the number essential for the actual transport of the material. The filling, bunging, labelling and loading into the transport vehicle are also Costly preludes, and since a full carboy weighs 145 lb., two men -are always necessary for its handling. It is quite common for a single consumer to use over 250 tons of acid per annum, taken in weekly instalments of 5 tons, The cost of the carboys required for the transporting and.storing of this quantity involves a capital outlay of £80, and the maintenance, including interest, depreciation and repairs, involves a further annual expenditure of Lid, to which items must be added to the cost of trans port, which naturally varies with the distance, but which usually exceeds £125.

In the case of the lower-quality hydrochloric acid, commonly called muriatic and used mainly in galvanizing, tin-plating, tube making, and in the cold-rolling industries, the function of the acid is that of a tool for scaling the metal; it is thus a consumable tool, adding to the cost of the products, which are already suffering from strenuous competition. With an average cost of 13 10s. per ton delivered, 30 per cent. represents the cost of conveyance. For the higher qualities of this acid, the cost of conveyance is approximately 17i per cent. Nor is this the complete cost incidental ,th the use of carboys, for the consumer must unload and reload the

empties, provide floor space for quite 200 of them and distribute them to the process vessels about the factory. In addition, he must foot the bill for breakage, whilst spillage and the difficulty of absolutely emptying some 5,000 carboys addan appreciable amount to the ultimate expense. The cost of conveyance begins at the source of the acid, its manufacturer being necessarily the first to feel it.

Fortunately, it would appear thatthe methods of storage at present employed will, before long, succumb to the economies of a. more modern system in transport and handling, and in this respect it will be one of •the last of the essential basic materials to. throw off the restraining chains of antiquated procedure.

The key to the problem lies in eliminating the carboy, which is thc cause of at least 50 per cent. Of the cost of transport and distribution. The alternative is to employ much larger containers, the adaptation of which must always depend upon co-operation between the acid makers and the consumers. TC1 do away with the carboy involves the provision of large transport tanks by the acid makers and their concomitant large storage tanks on the part of the consumers, so that they can receive the acid in bulk.

For many years the practical difficulties in carrying out this system have been considerable. The few materials resistant to acid action and capable of withstanding the stresses of transport have been so heavy and costly as to be almost prohibitive. During recent years rubber compounded with sulphur, and known under the commercial names of ebonite and vulcanite, has provided a material -which would adhere to wood and steel, thus affording considerable protection and making possible the construction of much larger containers. Since, however, the application of ebonite to steel vessels involves the process of vulcanizing the ebonite to the steel, the size of the Vessel le limited by thc size of the vulcanizer, an alternative being a larger vessel constructed in relatively small sections bolted together ; consequently the use of ebonite involves a more expensive construction of the tank it protects and its application, is costly, relative to the value of the material itself. Ebonite cannot, therefore, be said to have solved the problem in a satisfactory manner. Moreover, the great difference in expansion compared with steel, its relatively low tensile strength and its perfect adhesion render it prone to fracture under varying temperatures and as the result of vibration,

However, in recent times the art of chemically welding a soft flexible sheet rubber to steel by means of a chemical flux has solved the problem of applying a suitable material to steel or wood of any size and in situ. The material is known as acid-rubber and consists of some 90 per cent, of pure canutchouc, which is the resistive element in all rubber compositions. It is compounded with just sufficient foreign constituents to give the maximum of tensile strength without sacrificing extensibility. The result is a material so elastic as to withstand any ordinary stresses without fracture. In the form of thin sheets it provides a light, cheap lining inert to acid action and particularly appropriate to the construction of tanks and containers, not only for acids. but for many other corrosive liquids, such as caustic soda and potash, calcium chloride, copper sulphate, ammonia, tanning extracts, sea water, acetic acid, vinegar, etc.

Actually, the acid rubber lining becomes the tank proper, leaving to the steel outer easing the duty of giving the desired shape to the container and carrying the Weight of the liquid. Several

manufacturers of acids have Compressed air is employed for emptying the taken the initial step by tanks on vehicle and trailer. It is obtained offering the economies ef from a Lacy-Hulbert air pump driven from the bulk transport of acid th conchassis gearbox via alongitudinal shaft and sumers by providing road double-link belts.

tankers capable of delivering as much as 20 tons per load. The acceptance of acid in bulk, however, requires the provision of suitable storage tanks and the accessories for distributing the liquid to its final destinations. At present, the inducement offered by makers to users for bulk storage is rarely lees than Sc. per ton, but in favourable circumstances it has been 10e. to 158. During this transitional stage, while 80 per cent. to 90 per cent, of the acid is still transported in carboys, it is obvious that the makers are not realizing the full economies which their new equipment will afford when employed to capacity. Hence it remains for consumers to speed the movement before they can hope to participate to the fullest extent in the possible economies.

Since an appropriate storage tank is a complement of bulk conveyance, whether by rail or road, the Same attention must be given to the development of the storage tank. ' Some time ago we gave particulars of the use of acid rubber for acid tanks by a well-known rubber manufacturer. We now wish to point out that Messrs. Newitt and Son, consulting and contracting chemical engineers, of 46, Southampton Row, London, W.C.1, are carrying out a large amount of this work. The storage tanks which they supply

are standardized to one design, their tonnage capacities being 5, 10, 15, 20 and 25. They are cylindrical in section and constructed of mild steel with fumeless roofs and suitable inlets and outlets of flexible acid rubber, the filling conduits having a flange standardized to interlock with the deliveryhose flange on the acid maker's road tankers, a calibrated gnat indicator showing the acid received and withdrawn.

A 10-ton storage tank suitable for a consumption of 250 tons per year has a capacity of 111 tons, is 7 ft. 9 ins. in diameter, and, with a generous complement of distributing conduit, cocks, etc., can be delivered for £100. It has a

transport life of at least 10 years. The cost would be recouped in a little over a year with a reduction of Sc. per ton in the price of acid. The choice of appropriate conduit lies between ebonite pipes, iron pipes lined with acidrubber and flexible acidrubber. The first two are relatively costly and can only be made in ehost lengths, but flexible acid-rubber, consisting of a special inner tube reinforced by canvas and steel wire and protected outside from mechanical abrasion, Overcomes these disadvantages.

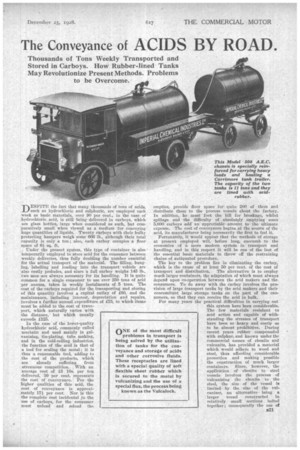

The acid-transport unit which we illustrate is a Model 508A.E.C. chassis, specially reinforced for hauling a trailer and extra heavy. loads. The chassis carries a mildsteel tank which has a capacity of 6 tons and is lined with special acidrubber vulcanized to the interior surface by the VnIcalock process. The trailer is a Carrimore product and care ties a tank of the same type, but of 5-ton capacity. All the inlets and outlets for acid and compressed air are assembled on the lids of the manholes and. are, therefore, readily acceseible for cleaning or repair. Both tanks are discharged by compressed air, the compressor employed being a Lacy-Hulbert, which is driven from the gearbox. .

• Either tank can be discharged in 15 minutes, or the two simultaneously. The air conduits are of the flexible rubber type with special joints, and the acid can he elevated to a height of 80 ft. if required. This is a concession of considerable value to consumers, since storage tanks can be filled although they be sufficiently elevated to distribute the 'acid by gravity to any part of the factory.

On the chassis are large hose and tool lockers, one being eqnipped with a three-section flexible acid-rubber delivery conduit. On one of these sections is a Dexonite cod{ and safety nozzle for the filling of open venel and carboys. By this arrangement the conduit may be made 10 ft., 20 ft., or 30 ft. long as cireumetances require.

The development of a piece of composite plant -to meet special conditions, such as these, necessarily involves the experience of the chemical engineer, and the design and assembly of the equipment on this particular vehicle have been placed in the hands of Messrs. Newitt and Sou by the Imperial Chemical Industries, Ltd. (Alex. Walker and Co., Ltd.).