, C 11 1 r-H -111.31 _1 1

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

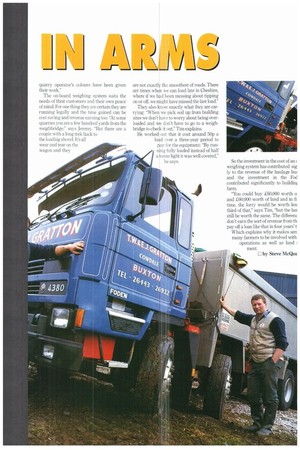

Take one hard-working Foden, a pair of energetic farming brothers, add them to quarry-rich Derbyshire and you have the recipe for a successful tipper business.

JJ ust how many farmers also operate a haulage business is not clear, but the advantages of having a foot in both amps are clearly demonstrated in the Derbyshire village of Cowdale.

Brothers Tim and Jeremy Gratton run a one-truck tipper operation called TW&EJ Gratton, which generates enough revenue to help support their farming activities and a little more besides. They do this by combining four of the factors essential to any successful business: a good geographical location, investment in the right equipment, teamwork and careful management.

Geological resources

Rather fortuitously, the farm is within three minute's drive of one of the centres of commercial exploitation of the Derbyshire peaks' geological resources: "There are that many quarries around here that most of the farmers are hauliers as well," says Jeremy Gratton. If you have a farm you've got a haulage yard—there's no problem finding a depot or paying for parking.

But a good base doesn't guarantee success, so the brothers decided that a powerful workhorse and some close co-operation in its management would be needed if the haulage side of their business was to succeed. Their first vehicle was a 320hp Cummins-powered Foden bought through ClIfs classified pages.

They were impressed by its reliability, so when it was time to find a replacement they stuck with Foden: a brand new 4380, complete with Twin Splitter Eaton gearbox, Wilcox insulated body, F.dbro front-end tipping gear and PM Electronics on-board weighing equipment.

"We had to have something to cope with the hill work coming back up over the Cat and Fiddle," says Tim Gratton, who does the bulk of the driving while Jeremy takes the lion's share of the farm work.

Their team effort accounts for the vehicle's high productivity: "Our ideal is to run it for the equivalent of a day and a half each day," says Tim. "The earlier loads are the easiest to organise and if we can get a very early tip— which we call a whoosher--we've got an extra load under our belts Jeremy will do it and I'll take over later on."

Late loading quarries and a neat switch of drivers prolong the vehicle's working day. In a typical 24-hour period Tim could end one day by loading stone at Dowlow quarry just along the road, while Jeremy will begin the next by tipping near Manchester at around 06:00hrs. A return trip before the traffic builds up leads to a reload in Buxton, followed by a tip and reload before Tim takes over.

Tim would then deliver a late morning load of stone to Cheshire before sourcing loads of topsoil or sand mixed for top dressing of golf courses for a Cheshire-based client. A load of sand sees him back to Tunstead quarry, near Buxton.

"If I'm running out of time Jeremy will come and meet me, or go and tip the last one and reload ready for the morning," says Tim.

Vehicle utilisation can run up to 200%, depending on the availability of work. For example, if there is road repair work about Jeremy will run the vehicle at night while Tim takes the day shift.

Second driver

Occasionally there can be a conflict with the farm work, but so far there has been no move to take on a second driver to release Jeremy for the farm.

"We thought about getting another driver and keeping the first vehicle we had, but it's a question of finding the right driver," says Jeremy. "We do know good drivers but they are working for other people. The difference is that if our vehicle gets laid up, there is no-one else to pay."

This means expansion of the haulage business is restricted to the hours Jeremy can add while still committed to the farm. Some might say that this shows a lack of entrepreneurial ambition, but it could equally be argued that it is evidence of their close managerial control over a business which is as big as it needs to be.

Close proximity of the nearby quarries means that the Gratton vehicle is extremely load efficient, with few time consuming runs back to the depot and the minimum of empty mileage. Careful management of the client base, allied to an investment in the on-board weighing system, is further evidence of sound business practice.

For example, working directly for the quarry operators has been shunned in favour of working for stone merchants who tend to work more in tune with the operators' needs, says Jeremy: "We might have to ring the stone merchants each night and they might sometimes only be able to give us the first two loads before we have to ring in, but that's opposed to working at a quarry where you have to queue up at 6am to get whatever there is. That will be after the owner operators in the quarry operator's colours have been given their work."

The on-board weighing system suits the needs of their customers and their own peace of mind. For one thing they are certain they are running legally and the time gained can be cost saving and revenue earning too: "At some quarries you are a few hundred yards from the weighbridge," says Jeremy. "But there are a couple with a long trek back to the loading shovel. It's all wear and tear on the wagon and they are not exactly the smoothest of roads. There are times when we can load late in Cheshire, where if we had been messing about tipping on or off, we might have missed the last load."

They also know exactly what they are carrying: "When we pick soil up from building sites we don't have to worry about being overloaded and we don't have to go to a weighbridge to check it out," Tim explains.

He worked out that it cost around 50p a load over a three-year period to pay for the equipment: "By running fully loaded instead of half a tonne light it was well covered," he says. So the investment in the cost of ant weighing system has contributed sig ly to the revenue of the haulage bui and the investment in the Fod contributed significantly to buildim farm.

"You could buy £60,000 worth o: and £60,000 worth of land and in ft time, the lorry would be worth lesi third of that," says Tim, "but the lan still be worth the same. The different don't earn the sort of revenue from th pay off a loan like that in four years' t Which explains why it makes sen: many farmers to be involved with operations as well as land ment.

0 by Steve McQuE