SIRDA SHONI THEW.

Page 50

Page 51

Page 52

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Says John F. Moon, A.

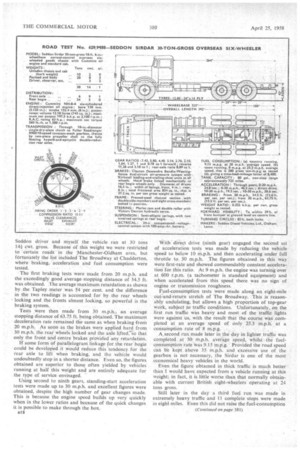

ALTHOUGH tested at almost 301 tons gross weight, the new Seddon Sirdar normal-control overseas sixwheeler was shown to be faster, safer, more lively and decidedly more economical than most normal British heavy haulage vehicles running at up to 10 tons lighter. In fact, on one fuel-test run a time-load-mileage factor of 8,400 was achieved—a figure that I feel sure will remain a record for some time to come and one at least 25 per cent. better than anything hitherto obtained on test by 77w Commercial Motor.

The Sirdar, which was described exclusively in The . Commercial Motor on April 4, has been designed for fast long-distance haulage in those countries overseas where gross-weight and axle-loading restrictions are not as severe as in Great Britain. The Cummins oil engine was chosen as being most suitable for such conditions, in that it gives good fuel economy at high speeds with ample power for acceleration and fast hill-climbing.

World-wide Servicing A further advantage of this unit is that, although now manufactured in Great Britain, it is identical in all respects with the original American-made version, so-that the existing world-wide Cummins service and spares facilities are available to operators of the Seddon.

The NH-B-6 engine used in the Sirdar is a 12.18-litre six-cylindered unit with a net output of 197.5 b.h.p. Its net torque output is 560 lb.-ft. at 1,500 r.p.m. Although this is higher up the engine-speed range than is normally acceptable for good overall performance, the torque characteristics are such that there is little fall-off in output as the engine speed reduces, and the unit pulls away smoothly from as low as 400 r.p.m. in direct drive.

Although basically conventional in general construction the Cummins unit has two unusual features. One is the use of two inlet and two exhaust valves for each cylinder, and the other is the PT (pressure-time) injection system. This system is much simpler than layouts employing plunger-type pumps and it dispenses with the need for injection-pump timing, calibrating and phasing.

A fuel pump acts as a lift pump and delivers fuel to individual injectors by way of a system of branch pipes. The pump has a regulator which controls the pressure of fuel delivery to the injectors, and a governor and throttle which, independently of the regulator, additionally controls

a16

the fuel pressure to the six cam-actuated injectors. Fuel is circulated at a low pressure to and through the

injectors whenever the engine is running. The actual injection point and the injection pressure are determined by the injectors themselves, which are actuated by the engine camshaft through a conventional system of push-rods and rockers. Thus injection timing is fixed in relation to valve timing and is not dependent -upon correct replacement of the pump.

Complementary to the use of an Americandesigned oil engine, the Seddon engineers considered it wise to employ an American gearbox, particularly as the gearbox chosen is frequently Mated to Cummins units in the U.S.A. and its spread of ratios is well suited to the Cummins torque characteristics.

The gearbox is the Fuller. Roadranger R960 10-speed unit with an overdrive-top ratio. A direct-drive-top version is offered in the Sirdar tractor. The Fuller box is essentially a fivespeed, constant-mesh unit, integral with which is a two-speed, air-operated auxiliary gear. This auxiliary gear does not " split" the main ratios, but acts as a doubling-up gear, so that there is one range of five low forward speeds and one range of five high speeds. The vehicle is started in first or second gear, using the low auxiliary ratio, and normal changes are made as far as fifth gear. For the next change, high auxiliary is engaged and then normal gear changes are made through the box from first to fifth, these ratios actually being sixth to tenth.

Thus gear-changing is simplified when compared with some transmissions employing auxiliary gearboxes, as there is no question of split-changing, except between fifth and sixth, and therefore no doubt in the driver's mind as to which particular ratio to change to next.

The Cummins engine and Fuller gearbox are mounted as a unit. At the front a Cummins-designed solid trunnion mounting is employed. It consists of a 5-in.-diameter rod carried on the front of the crankcase, which is clamped rigidly to the frame but allows slight radial movement.

At the clutch housing, two Metalastik rubber bushes are employed, these acting also as torque-reaction members, whilst at the tail of the gearbox there are two Metalastik bushes in tension to give added support. The 18-in.diameter single-dry-plate clutch is actuated by air pressure.

Each side member of the robust chassis frame consists of two channelsection members, one inside the other. The Kirkstall double-drive bogie incorporates hypoid-and-epicyclic doublereduction axles. The split-circuit airpressure braking system has cam-type units at the wheels. Steering is hydraulically assisted.

Normal-control chassis layout was chosen to provide ample space for the driver and passengers, good engine accessibility and reduced noise and heat in the cab. The cab and frontal bodywork are of Seddon design and manufacture, and steel is used throughout. The Chapman driving seat is separate from the two-man passehger seats and is adjustable vertically and longitudinally, in addition to being mounted on a hydraulic pedestal which can be adjusted to suit varying weights of driver.

Good all-round visibility is provided by the cab glazing and adequate ventilation is given by winding glasses in the doors and scoop-type quarter-light ventilators. The windscreen panel in front of the driver can be opened, as can the three rear window lights. The Sirdar is available with either leftor right-hand drive.

The vehicle supplied for test was the first to be produced and had covered only a small mileage. It was a left-handdrive version and, complete with cab, its kerb weight was .10 tons 2 cwt., the front wheels carrying 5 tons 2 cwt.

With substantial test body and load, the Sirdar turned the scale at 30 tons 101 cwt. and the front wheels were carrying 1 ton 3-1 cwt. of the imposed load. Complete with

Seddon driver and myself the vehicle ran at 30 tons 141 cwt. gross. Because of this weight we were restricted to 'Certain roads in the 'Manchester-Oldham area, but fortunately the list included The Broadway at Chadderton, where. braking: acceleration and fuel consumption were tested.

The -first braking tests were made from 20 m.p.h. and the exceedingly good average stopping distance of 34.5 ft. was obtained.. The average maximum retardation as shown by the.Tapley meter was 54 per cent. and the difference in the two readings is accounted for by the rear wheels

• locking and the fronts almost locking, so powerful is the braking system.

Tests were then made from 30 m.p.h, an average stopping distance of 63.75 ft. being obtained. The maximum deceleration rate remained the same as when braking from 20 m.p.h.. As soon. as the brakes were applied hard from 30 m.p.h. the rear, wheels locked and the axle lifted,in that only the front -and Centre brakes pr-oVided any retardation.

If some form Of parallelogram linkage for the rear bogie could be developed it would reduce this tendency for the rear axle to lift when braking, and the vehicle would undoubtedly stop in a shorter distance. Even so, the figures obtained are superior to those often yielded by vehicles running at half this weight and are entirely adequate for the type of service envisaged.

Using second to ninth gears, standing-start acceleration tests were made up to 30 m.p.h. and excellent figures were obtained, despite the high number of gear changes made. This is because the engine speed builds up very quickly when in the lower ratios and because of the quick changes it is possible to make through the box_

With direct drive (ninth gear) engaged the second set of acceleration tests was made by reducing the vehicle speed to below 10 m.p.h. and then accelerating under full throttle to 30 m.p.h. The figures obtained in this way were first-rate and showed commendably constant acceleration.for.this ratio. At 9 m.p.h. the engine was turning over at 600 r.p.m. (a tachometer is standard equipment) and when accelerated from this speed there was no sign of

engine or transmission roughness. .

Fuel-consumption tests were made along an eight-mile out:and-return stretch of The Broadway. This is reasonably undulating, but allows a high proportion of top-gear work, subject to traffic conditions. 'Unfortunately, on the first run traffic was heavy and most of the traffic lights were against "us, with the result that the course was completed at an average speed of only 25.3 m.p.h. at a consumption rate of 8 m.p.g. :

A second run made later in the day in lighter traffic was completed at .30 m.p.h. average speed, whilst • the fuelconsumption rate was 9.15 m.p.g. Provided the road speed can he kept above 35 m.p.h. and excessive use of the gearbox is not necessary, the Sirdar is one of the most economical heavy vehicles in the world.

Even .the figure obtained in thick traffic is much better than I would have expected from a vehicle running at this weight: in fact, it is little worse than that normally obtainable with current British eight-wheelers operating at 24 tons gross.

Still later in the day a third fuel run was made in extremely heavy traffic and 11 complete stops were made in eight miles. Even this did not raise the fuel-consumption (Continued on page 381)

rate unduly, the commendable figure of 5.5 m.p.g. being obtained at an average of 25 M.p.h.

There are two further factors to be taken into consideration with regard to the fuel figures obtained during these tests. The first is that the chassis, being almost brand-new, was by no means loosened up and its mechanical efficiency would be at its lowest.

• The second is that at the end of each run the chassis had to be reversed into a side road and then driven forward, so that the fuel consumed could be measured at the same spot of road as when the tank was topped up at the start of each trip. Bearing these points in mind it is possible that overall consumption figures in the region of 10 m.p.g. could be obtained in service. • Unfortunately, because of load restrictions it was not possible to use Buckstones Road—the usual Seddon test hilt Instead, the Sirdar was taken through the back streets of Oldham and out along the A62 road in the direction of Huddersfield.

This is all ups and downs and is constantly used by heavy traffic travelling between Lancashire and Yorkshire. Many laden vehicles were overtaken on up gradients and few unladen lorries managed to overtake us.

Although some of the climbs lasted five minutes, no abnormal oilor water-temperature rises were recorded. The highest readings observed were 120° F. and'155°• F. respectively, compared with the normal figures of 100' F. and 150° F. when running on reasonably level roads (the ambient temperature .during the tests was between 45° F. and 50° F.).

The lowest gear used on any hill was fifth, which was employed up the west side of Scouthead. On the steepest part of this climb the road speed dropped to 6 m.p.h., the engine turning over comfortably at 1,200 r.p.m.

On the down gradients there was no sign of brake fade, although normal woven facings were fitted, and the vehicle was safe at all times. It would, however, not be difficult to introduce an exhaust brake, which would promote safety and prolong facing life in hilly areas. • The size of the Sirdar belies its handling characteristics, for it is extremely easy to manage. The steering, which is assisted by a Vickers Detroit hydraulic servo, is Pleasantly light, though not to such an extent as to cause wandet and lack of castor action. The servo is highly effective at low speeds, shunting demanding no more effort of the driver than is required on the open road. • • Gear-changing could hardly be better on a constant...mesh design, and the air-operated clutch is light and smooth in Operation." Excellent suspension, even over rough surfaces, helps to make the Sirdar safe When cornering quickly.

• The engine was surprisingly quiet at normal speeds and even when pulling hard it did not emit distracting noises, its presence being shown more by a deep purr than by a harsh rattle. When driving at top speed (43 m.p.h.) the engine noise does not increase unduly and at all speeds the transmission is reasonably quiet.

There was no time to conduct maintenance tests, but it is obvious that normal service will not present undue difficulty. Engine accessibility is particularly good, even with only the two hinged bonnet panels open, and for extensive attention the upper and side panels can be unbolted and removed to give good access to all engine auxiliaries..

In addition to being available as a 30-ton-gross sixwheeled rigid chassis the Sirdar is also to be offered as a prime mover • in versions suitable for gross train weights of up to 100 tons. For such applications the basic chassis specification remains much the same, the principal difference being that supercharged or turbocharged models of the Cummins engine (with ratings of up to 335 b.h.p.) will be used.