, For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the sender of the best letter which we publish on this page: all others are paid for at the rate of a penny a line, with an allowance far photographs. All notes are edited before being published. sweatisa your employer's name, in confidence, as evidence of good faith. Address, D., M. and F., "The Commercial Motor," 745, Bosebery Avenue, LOnclon, E.C. 7.

Lamps Alight— Light your lamps at 8.43 in London, 9.54 in .Edinburgh, 9.14 in Newcastle, 9.1 in Liverpool, 8.53 in Birmingham, 8.53 in Bristol, and 9.44 in Dublin.

Lubricating the Driving Chain of a Steam Wagon.

The sender of the following communication has been awarded the Ws. prize this week.

[1850] "A.W." (Dewsbury). writes :—" It is • very Aiffieult to lubricate satisfactorily the chain of a !steam wagon, or, indeed, d any chain-driven chassis. Nty experience has been that a chain can be well oiled on starting -outs and, after a few miles, the rollers, on examination, would be found to be quite bright and dry. The result is of course, rapid wear of the rollers, and, after a time, their breakage. If one uses thick oil, or grease, putting it on witha brush it does not get between the side plates, and therefore fails to lubricate the pins and rivets inside the rollers. This procedure is* therefore, as unsatisfactory as the other.

" I had selieral ideas as to how to surmount the difficulty. At one time it occurred to me that it should be an easy matter to rig up a mechanical lubricator fitted with a grooved pulley, and driven either from the second motion Shaft or the back axle. Upon investigating it more closely, however, I cam.e to -the conclusion that. this would be a troub esome job and would not be satisfactory when erec el. Eventually I thought of quite a simple plan, arid as this has been in use for some time, and is working satisfactorily, no doubt your readers will be interested. Very little explanation is needed over and above the sketch and which I enclose [which we have had redrawn.—En.].

" It will be seen that an oil box was fitted.inside the cab, and a pipe taken from it so as to drip on to the chain just as it passes over the front sprocket. There is no difficulty about securing the pipe. In my ease I fastened it to the woodwork of the body by staples. The feed can be adjusted, by means of a tap, from an occasional drip to running quite freely on the chain. As soon as the wagon stops the tap can be turned off and the feed therefore ceases. The oil box is accessible.. It-can easily be. exarainedg and replenished when necessary. I had it made long and narrow so that. itwould project as little as possible into the inside of the cab."

Steam Wagon Steering Chains.

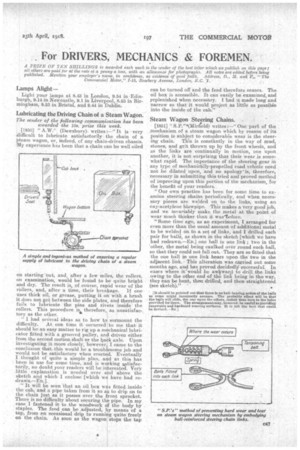

[1851] " S.P."*(Mirfield) writes :—" One part of the _mechanism of a steam wagon which by reason of its position is subject to -considerable wear is the steering chain. This is constantly in the way of mud, stones, and grit thrown iv by the front wheels, and as the links are continually in motion, one upon another, it is not surprising that their wear is somewhat rapid. The importance of the steering gear in any type of mechanically-propelled road vehicle need not be dilated upon, and no apology* is, therefore, necessary in submitting this tried and proved method of improving upon this portion of the mechanism, for the benefit of your readers.

"Our own practice has been for some time to examine steering chains periodically, and when neees-: sary pieces are welded On to the links, using an oxy-acetylene blowpipe. -This makes a very good job, and we invariablymake the metal at the point of wear much thicker than it wasIsefore.

"Some time ago, as an experiment, I arranged for even more than the usual amount of additional metal to be welded on to a set of links, and I drilled each pair for balls, as shown in the sketch [which we have had redrawn.—En.] one ball in one link ; two in the 'other, the metal being caulked over round each ball, so that they could not fall out. They are so fitted that the one ball in one link bears upon the two in the adjaeent link. • This alteration was carried out some months ago, and has proved decidedlY successful. In eases .where it' would be awkward to drill. the links owing to the other end of the link being in the, way, they an be bent, then drilled, and then straightened (see sketch)."

[It should be pointed out that there Is no ball-bearing action of the balls as some might =mealy assume. The probable effect will he that the balls will slide, the one upon the others, rather than turn in the holes provided for them. The arrangementmay, however, be useful as providing renewable and hardened wearing surfaces. It is net the best that could be devised.—En.1