ROUGH RIDING IN CC FORT

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

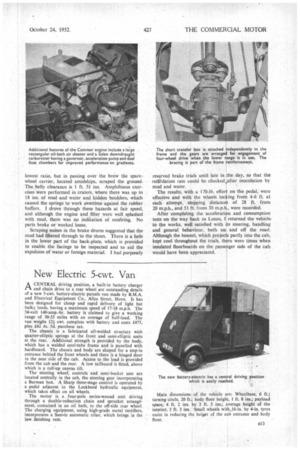

1 rence J. Cotton. m.I.R.T.E. ITi not unusual to be ejected from the driving seat when testing chassis over the Tank proving grounds at Farnborough, but this did not happen with the Commer 4 x 4, which rode smoothly across the broken ground at high speed. Although developed from the standard Superpoise 5-tanner, it has a specially designed suspension system, with trunnion-ended springs and shock absorbers at both axles. Medium-capacity loadcarrying vehicles designed specifically for cross-country work normally have full forward control to equalize the load on both axles, but the Commer four-wheeldrive chassis inherits normal control from the Superpoise.

. It has been developed to military requirementsfor the Ministry of Supply, and employs the 5-tanner frame, reinforced during manufacture, and a vertical version Of the 41-litre overhead-valve underfloor petrol engine. This unit develops 95 b.h.p. at 3,000 r.p.m., the governed speed, and 225 lb.-ft torque is yielded at 1,200 r.p.m.

It has a seven-bearing counter-balanced crankshaft and Solex downdraught carburetter incorporating the governor and accelerator pump. In addition, the carburetter has dual float chambers for operation on steep gradients. A special device is fitted for starting at sub-normal temperatures.

Additional features, provided to meet exceptional operating conditions, include a large rectangular oilbath air cleaner, with a capacity of 190 cubic ft. per mm., and a pressure cooling system which allows for a 110-degree F. difference between ambient and water temperatures. The cooling system employs a six-bladed 18-in, cowled fan and five-row radiator block. The radiator cap is set for a pressure of 10 lb. per sq. in.

The standard 12-in, clutch and four-speed gearbox, with constant mesh for the top and third ratios, are mounted in union with the engine, and there are two S.A.E./S.M.M.T. six-bolt facings provided for powerdriven. attachments. The two-speed transfer box is carried independently in the frame, supported on a three-point rubber mounting and linked to the gearbox by a short shaft with two Layrub joints. This is a compact unit with a high ratio of 1.269 to t and frontwheel drive is automatically engaged when the lower gear of 2.175 to 1 is brought into use.

a8 Drive to the axles is taken from a shaft in the lower part of the transfer box and the spiral-bevel final-drive assemblies of 6.57 to I are interchangeable. All the drive shafts are fully floating, the front axle being a robust pressing with flanges welded at the ends for attaching the housings enclosing the Tracta universal joints. The sump is modified to give clearance above the front-axle drive unit.

The chassis frame is reinforced amidships by welded plates and an additional V-bracing is interposed between the back of the cab and the cross-member supporting the transfer box. The cross-member above the rear axle is altered to allow for the attachment of the shock absorbers, which are inclined from the vertical to combat chassis roll. The trunnion-ended springs are advantageous under exceptional articulation.

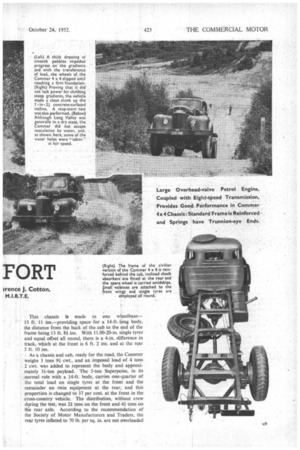

Modifications to the standard superstructure include an expanded metal grille at the front of the bonnet and air vents in the sides to promote cool air circulation around the engine. The front wings have valence extensions and the head lamps are recessed. The side lamps are attached to the top of a sturdy bumper bar. The doors have swivelling quarter-lights for improved ventilation and glazed corner panels are fitted. The one-piece windscreen is made to open. This chassis is made in one wheelbase13 ft. 11 ins.—providing space for a 14-ft.-long body, the distance from the back of the cab to the end of the frame being 13 ft. 81 ins. With 11.00-20-in, single tyres and equal offset all round, there is a 4-in, difference in track, which at the front is 6 ft. 2 ins, and at the rear 5 ft. 10 ins.

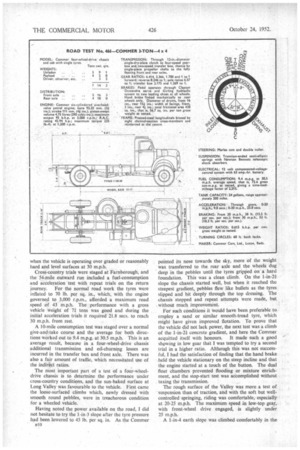

Ask chassis and cab, ready for the road, the Commer weighs 3 tons 91 cwt., and an imposed load of 4 tons 2 cwt. was added to represent the body and approximately 3+-ton payload. The 5-ton Superpoise, in its normal role with a 14-ft. body, carries one-quarter of the total load on single tyres at the front and the remainder on twin equipment at the rear, and this proportion is changed to 37 per cent. at the front in the cross-country vehicle. The distribution, without crew during the test, was 2i tons on the front and 41 tons on the rear axle. According to the recommendation of the Society of Motor Manufacturers and Traders, the rear tyres inflated to 70 lb per sq. in. are not overloaded a9 when the vehicle is operating over graded or reasonably hard and level surfaces at 30 m.p.h.

Cross-country trials were staged at Farnborough, and the 54-mile outward run included a fuel-consumption and acceleration test with repeat trials on the return journey. For the normal road work the tyres were inflated to 70 lb. per sq. in., which, with the engine governed to 3,000 r.p.m., afforded a maximum road speed of 43 m.p.h. The performance with a gross vehicle weight of 74 tons was good and during the initial acceleration trials it required 21.8 secs. to reach 30 m.p.h. from rest.

A 10-mile consumption test was staged over a normal give-andtake course and the average for both directions worked out to 9.4 m.p.g. at 30.5 m.p.h. This is an average result, because in a four-wheel-drive chassis additional transmission and oil-churning losses are incurred in the transfer box and front axle. There was also a fair amount of traffic, which necessitated use of the indirect ratios.

The most important part of a test of a four-wheeldrive chassis is to determine the performance under cross-country conditions, and the sun-baked surface at Long Valley was favourable to the vehicle. First came the loose-surfaced climbs which, newly dressed with smooth round pebbles, were in treacherous condition

for a wheeled vehicle. • Having noted the power available on the road, I did not hesitate to try the 1-in-3 slope after the tyre pressure had been lowered to 45 lb. per sq. in. As the Commer

pointed its nose towards the sky, more of the weight was transferred to the rear axle and the wheels dug • deep in the pebbles until the tyres gripped on a hard foundation. This was a clean climb. On the 1-in-21 slope the chassis started well, but when it reached the steepest gradient, pebbles flew like bullets as the tyres slipped and bit deeply through the top dressing. The chassis 'stopped and repeat attempts were made, but without much improvement.

For such cOnditions it would have been preferable to employ a sand or similar smooth-tread tyre, which might have given improved flotation. To prove that the vehicle did not lack power, the next test was a climb of the 1-in-21 concrete gradient, and here the Commer acquitted itself with honours. It made such a good showing in low gear that I was tempted to try a second trial in a higher ratio. Although this was not successful, I had the satisfaction of finding that the hand brake held the vehicle stationary on the steep incline and that the engine started at a touch of the button. The dual float chambers prevented flooding or mixture enrichment, and the stop-start test was accomplished without taxing the transmission.

The rough surface of the Valley was more a test of suspension than of traction, and with the soft but wellcontrolled springing, riding was comfortable, especially at 20-25 m.p.h. The maximum speed in low-top gear, with front-wheel drive engaged, is slightly under 25 m.p.h.

A I-in-4 earth slope was climbed comfortably in the

lowest ratio, but in passing over the brow the sparewheel carrier, located amidships, scraped the ground. The belly clearance is 1 ft. 51 ins. Amphibious exercises were performed in craters, where there was up to 18 ins, of mud and water and hidden boulders, which caused the springs to work overtime against the rubber buffers. I drove through these hazards at fair speed, and although the engine and ,filter were well splashed with mud, there was no indication of misfiring. No parts broke or worked loose_ Scraping noises in the brake drums suggested that the mud had filtered through to the shoes. There is a hole in the lower part of the back,plate, which is provided to enable the facings to be inspected and to aid the expulsion of water or foreign material. I had purposely

reserved brake trials until late in the day, so that the refirrdation rate could be checked.after inoculation by

mud and water.

The results, with a I70-lb. effort on the pedal, were effective and with the wheels locking from 4-6 ft. at each attempt, stopping 'distances of 28 ft. from 20 m.p.h., and 53 ft. from 30 m.p.h., were recorded.

After completing the acceleration and consumption tests on the way back to Luton, I returned the vehicle to the works, well satisfied with its steering, handling and general behaviour, both on and off the road. Although the bonnet, which projects partly into the cab, kept cool throughout the trials, there were times when insulated floorboards on the passenger side of the cab would have been appreciated.