Vehicles in the Trials.

Page 3

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

The Broom Si Wade 3-ton Wagon (E46), entered by T. C. Aveling & Co., Ltd.

No vehicle in the trials has drawn forth so much goodhumoured banter as has the subject of our present article, but even those who were at first inclined to ridicule it must now admit that "it got there every time." When a new vehicle, and one presenting entirely new principles as far as commercial motoring is concerned, is brought before the public for examination, it is sure to be picked to pieces by its many critics, and there are really very few of these vehicles of unusual design which survive the criticism. The Broom and Wade wagon is one of the exceptions. Not only has her record during the trials been a good one but her condition after the trials was infinitely better than was that of some vehicles of well-known makes. We congratulate Mr. T. C. Aveling, of Central Chambers, New Street, Birmingham, upon the discrimination and enterprise which allowed this proof of merit to be available_ It is claimed for the Broom and Wade wagon that, owing to the successful development of the paraffin oil-engine, it can favourably compare with the steam wagon in low cost of fuel, and yet, at the same time, that it possesses all the advantages of the petrol engine in its wider range of action, lower tare weight, simplicity, and increased legal speed. We believe that, when the official figures for the cost of running are published by the Club, it will be found that the claims of T. C. Aveling and Company, Limited, which company solely handles these vehicles in the United Kingdom, and which entered No. E46, have been more than substantiated in practically all respects.

The engine has a single-cylinder, of 8 inches in diameter, and with a piston-stroke of like amount. At its normal speed of 650 revolutions per minute, the engine develops 2ob.h.p. The vaporiser is really a pocket in the combustion-head, and the paraffin is admitted during the stroke previous to that at which it is fired. It is sucked in with but a small quantity of air, the main air supply entering later, through a special valve. The inrushing air does not, therefore, cool the vaporiser. There is no carburetter, or spray chamber, but simply the pocket in the combustionhead already mentioned, and in that, after its arrival by suction, the paraffin is vaporised. The low-tension, make-and-brake, ignition lever and plug are also fitted into the vaporising chamber. Half-compression gear is fitted, and our third illustration shows the camshaft and valve tappets quite clearly, whilst the side view of the engine shows how the tappet operates on the val. through the medium of a rod and bell-crank.

The crankshaft is a pretty stiff job, and it is made of Willans and Robinsons' vanadium steel, which gives a tensile test of 37 tons per square inch, and an elongation of 25 per cent. on 2 inches. A very heavy flywheel is fitted, and to that fact is due much of the success of the vehicle. The whole of the engine parts are lubricated by a mechanical lubricator, and the earns and other revolving parts are enclosed in an oil-tight box. There are so few parts comprised in the engine, which is most accessible, that it occupies but a short time to take out the piston and connecting-rod for examination.

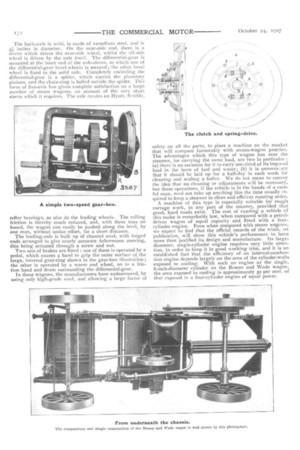

A metal-to-metal, cone-type clutch is fitted, as shown in the line drawing which we reproduce on the next page. In that view : A is the crankshaft ; B is the flywheel ; and C is the female cone, which is securely bolted to the flywheel. Projecting from the sliding, male cone (D), there are two lugs (M) through which drag-bolts are passed. The drive is then transmitted through the drag-bolts, and the compression spring (L), to the central member (G) through which a square hole is drifted to take the end of the gear-box shaft (F). Clutch and spring-drive are, therefore, combined in a simple and practical manner. The gearing is always in mesh, and is made of ample width to stand up to continued heavy wear. The drive upon each gear ratio is obtained by dog-clutches on the face of the large gear-wheels and similar dogs on a sliding member, as may clearly be seen in our illustration of the gearbox. Top and bottom covers enclose the gears, which then run in an oil-bath. Only two forward speeds and one reverse speed are provided. On the 3-ton wagons these are 5 and 8 miles per hour forward, and for the 4-ton wagon the forward speeds are 4 and 6 miles per hour, the reverse speed, in each case, being about 3 miles per hour. The pinion shaft, on which are the two, change-speed pinions, can be made to slide endwise, and the length of the teeth in the pinions is such that they are never wholly out of mesh with the large wheels, even when the pinion shaft is in the extreme position of its travel. The sliding motion of this shaft is used for the purpose of making the pinions (A) mesh with the ring (13), the dog-clutches being in neutral position at the time. The drive is then direct from the engine to the internal gear, and the vehicle will travel backwards.

Fixed on the outer end of the gear-box shaft, and partly hidden in our illustration, is a chain sprocket, from which, a Hans Renold, roller chain, of 2-inch pitch, drives the live back-axle, the centres being about 3 feet apart. The back-axle is solid, is made of vanadium steel, and is 3L inches in diameter. On the near-side end, there is a sleeve which drives the near-side wheel, whilst the off-side wheel is driven by the axle itself. The differential-gear is mounted at the inner end of the axle-sleeve, to which one of the differential-gear bevel-wheels is secured ; the other bevel wheel is fixed to the solid axle. Completely encircling the differential-gear is a spider, which carries the planetary pinions, and the chain-ring is bolted outside the spider. This form of live-axle has given complete satisfaction on a large number of steam wagons, on account of the very short sleeve which it requires. The axle rotates on Hyatt, flexible, roller bearings, as also do the leading wheels. The rolling friction is thereby much reduced, and, with three tons on board, the wagon can easily be pushed along the level, by one man, without undue effort, for a short distance.

The leading-axle is built up of channel steel, with forged ends arranged to give nearly accurate Ackermann steering, this being actuated through a screw and nut.

Two sets of brakes are fitted : one of these is operated by a pedal, which causes a band to grip the outer surface of, the large, internal gear-ring shown in the gear-box illustration ; the other is operated by a worm and wheel, on to a friction band and drum surrounding the differential-gear.

In these wagons, the manufacturers have endeavoured, by using only high-grade steel, and allowing a large factor of safely on all the parts, to place a machine on the market that will compare favourably with steam-wagon practice. The advantages which this type of wagon has over the steamer, for carrying the same load, are two in particular : (a) there is no occasion for it to carry one-third of its imposed load in the form of fuel and water; (b) it is unneces:ary that it should he laid up for a half-day in each week for cleaning and scaling a boiler. We do not mean to convey the idea that no cleaning or adjustments will be necessary, hut these operations, if the vehicle is in the hands of a careful man, need not take up anything like the time usually required to keep a steamer in clean and efficient running order. A machine of this type is especially suitable for rough cartage work, in any part of the country, provided that good, hard roads exist. The cost of running a vehicle of this make is remarkably low, when compared with a petroldriven wagon of equal capacity and fitted with a fourcylinder engine. Even when compared with steam wagons, we expect to find that the official records of the trials, on publication, will show this vehicle's performance to have more than justified its design and manufacture. Its largediameter, single-cylinder engine requires very little attention, in order to keep it in good working trim, and it is an established fact that the efficiency of an internal-combustion engine depends largely on the area of the cylinder-walls exposed to cooling. With such an engine as the single, 8-inch-diameter cylinder on the Broom and Wade wagon, the area exposed to cooling is approximately 50 per cent, of that exposed in a four-cylinder engine of equal power.