D&F McCARTHY

Page 21

Page 23

Page 24

Page 26

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

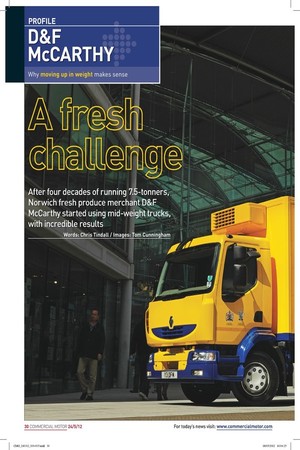

Why moving up in weight makes sense

After four decades of running 7.5-tonners, Norwich fresh produce merchant D&F McCarthy started using mid-weight trucks, with incredible results

Words: Chris Tindall / Images: Tom Cunningham

As with most sectors, timing is everything. But when your freight is fresh fruit, vegetables and dairy products, then the goods must often pass through the delivery chain in the blink of a transport manager’s eye.

For this reason, East Anglian family haulier D&F McCarthy has started using mid-weight trucks in its fleet after more than 40 years of relying on 7.5-tonners.

Soon after moving into a modern, spacious, new depot on the outskirts of Norwich, director Martin McCarthy decided to run two Renault 14-tonne Midlums and one 18-tonne Midlum with refrigerated bodies.

“We found we were doing more palletised orders and appealing to bigger customers than we were doing previously,” he explains. “We were moving away slightly from smaller caterers to other primary wholesalers. We had been shifting pallets on 7.5-tonners manually and stocking them manually. It made sense to leave them on pallets in the first place, but a 7.5-tonne truck doesn’t work like that. We worked with Matthew Alexander from [Renault dealer] Brands of Beccles and realised what we needed was to move up to mid-range trucks, which allow us more space and also enable drivers to become self-contained.” He says a lot of the decision-making was driven by its relationship with the dealer – modern trucks are complex things and it is important that they have someone that knows them inside out, as well as a thorough understanding of the work that needs doing.

The decision seems to be paying off. Martin describes the time savings and efficiencies as “incredible” , adding: “In the same time-scale we can deliver six tonnes of products from a mid-range truck compared with two and a half tonnes of product in a 7.5-tonne.

“It doesn’t suit all our customers, but it’s working really well for those that can take full pallets.” Martin is the fifth generation of McCarthys to work at the company, and in 2009 the first representative of the sixth joined in the shape of his nephew, son of his brother and fellow director Simon.

Keeping together

It’s the very definition of a family-run firm – there are six McCarthys listed as company directors. During CM’s visit, Martin’s mother pops in unannounced. You wonder what founder Thomas McCarthy would make of the business today, 135 years after the Irish immigrant first began selling fruit from a stall in London’s Drury Lane.

Martin says little is known about Thomas, but that it was his grandson (Martin’s grandfather Dan) who, along with Dan’s mother, transformed the business from stall selling to wholesale. By then it had moved to Great Yarmouth, and in 1939 it became a limited company.

“The sort of things [Dan] had to cope with were unreliable trucks that were always breaking down,” he says. “Signposts weren’t really evident either.” Not only that, but there were the Germans too. During an enemy air raid on Great Yarmouth in 1942, the warehouse was bombed.

At the time, D&F collectively wiped its hands on its trousers and carried on: “We were able to shrug it off and start again,” says Martin.

“In those days everything was dumped in corners and on the floor. Refrigeration was unheard of. You could run a fruit and veg wholesale business out of anything.” These days, it’s not so simple. Stock has a limited shelf life, particularly salads, and Martin says a lot of it hardly touches the ground while it moves from soil to store.

D&F McCarthy relies on “good housekeeping and knowledge of the product” to ensure good service.

“It’s not always the case that the next arrival of tomatoes will be the last to be sold,” he explains.

“If it is riper than existing stock, it’s moved to the front. You have to do that on a day-by-day basis. Stock is rotated and you never take your eye off the ball. There are very few products we stock that do not need daily checking.”

A state-of-the-art facility

Its state-of-the-art, temperature-controlled depot on the Broadland Business Park allows stock to be kept for an extra 24 hours if needed, with no deterioration in the product. The warehouse has facilitated the company’s expansion into dairy goods, too.

However, fruit and vegetables still dominate the schedules, accounting for 95% of D&F’s work.

“The food service sector is still something we can only see increase. We need to manage our fleet along those lines,” says Martin.

The majority of the company’s customers are based in the villages and market towns that are peppered along the county’s winding roads, and it was for this reason that it chose mid-range trucks to do the delivering: “We don’t want huge trucks doing that,” he says. “It’s acceptable with 7.5-tonners, and 14-tonne Midlums don’t look that much bigger.

“There’s not a perception that we are moving huge trucks into all of north Norfolk’s market towns.

“Because we’re in the service industry, our customers tend to tell us when they want goods – but there’s a fine line between what the customer wants and getting it at a price that makes sense to us.” Martin adds that at first there was apprehension among drivers that the Midlums were going to be a bit too large and unwieldy, but they have all been won round.

“That said, there is a sense that the 18-tonner might be pushing things. One of our biggest problems is the bodywork and mirrors being scraped by branches – the nature of north Norfolk’s roads is very rural!

“If we are not knocking our own mirrors, we’re knocking someone else’s – it’s always been our biggest replacement cost.”

The middle is always best

For the time being, there remains room for 7.5-tonners in the fleet, but as far as Martin is concerned mid-range marks the future.

“As our business is changing so rapidly, we really do need to play it by ear and see how things move. But I can see in the next three years the mainstay of our fleet will be mid-range,” he says. ■

PALLET TRUCKS AND TAIL LIFTS

D&F’s Midlums come with slide away tail lifts, fitted by Gray & Adams, and the increased payload allows them to carry pallet trucks too.

This means it no longer has to rely on customers’ forklifts and drivers spend less time unloading.

“Most of our customers just don’t have access to forklifts,” adds Martin. “They are small farm shops and high street shops. We are not having to rely on the customer to help unload the vehicle. If you stop in a busy high street, then two or three people unloading a lorry just to unblock the road is not great.

“[Pallet trucks and tail lifts] enable drivers to become self-contained. We can do palletised, curbside deliveries instead of handballing everything off trucks now. In our business, customers don’t care how we get it to them, as long as we do it on time, and we have reduced the time between drops and offloading using a pallet truck.” The company has 22 drivers, with 18 on regular delivery routes. Most of D&F’s customers are based within a 30-mile radius of its premises, but Martin says it is beginning to push out further afield, with deliveries in Essex and Cambridgeshire.

“We want to get out and back within a driver’s day,” he explains. “Because our customers are quite often small shops we have a number of deliveries to do, so we aim to get out early, do it all and get back. For fresh fruit and veg, nobody wants a delivery in the afternoon.”

FINANCIAL SENSE

The move to the Midlums is not just saving the company time; it also makes financial sense too in spite of the extra fuel costs.

Martin says that the majority of the delivery work takes place on country B roads and therefore it expects to get 12mpg-13mpg from a 14-tonner, compared with 15mpg-16mpg from a 7.5-tonne vehicle.

Replacing a vehicle because of its age has never been a company policy, so residual values are not an issue.

“By investing up front in good trucks and smart livery and not skimping on servicing, we can run a truck for up to10 years without any major issues,” he says. “With the reliability of modern trucks, we feel that every day from year five onwards comes at a discount and we really do get true whole life value out of our fleet.” Drivers of the 14-tonners, purchased for £73,000 each, are also paid more than those using the smaller vehicles, but Martin explains that even with these additional costs the cost per pallet of moving goods is still “far cheaper” even at a higher pay rate.

“As the date of drivers inheriting ‘grandfather rights’ recedes into the past, it was becoming increasingly difficult to find 7.5-tonne drivers and we were finding anyone with an LGV licence usually didn’t apply for 7.5-tonne work,” he adds. “Now we only look to recruit LGV-licensed drivers for our increasingly heavier fleet.

“When looking at the cost of moving each pallet of produce, it soon became very obvious that a 14-tonne truck could do it at a far better rate than a 7.5-tonne. If we could ensure that we could still meet our customers’ needs in terms of delivery times, the benefits were startlingly obvious.”

MOVING ON UP

D&F McCarthy was at its previous premises in central Norwich for 45 years before it moved to its new warehouse in 2010, and the decision ultimately transformed the business.

“It was quite a big leap,” says Martin. “At the previous premises, the business had already evolved into distribution from cash and carry. We had limited coolstore facilities and not all our trucks were refrigerated, so the next move had to be a big one. We upped our game considerably; we really raised the bar. This site is over three times larger.” The company deals directly with suppliers in France, Spain and Italy, and relies heavily on Holland for summer salads. Products can be air freighted into the country, or shipped through the ports or via the Channel Tunnel. The company generally relies on third parties to get the freight to its premises and then uses its fleet for outbound deliveries.

Most of its growth has been organic, with customers realising that they can add more and more products to their orders. “The whole coolchain operation just opens doors to us and makes deliveries of all kinds of products possible,” he explains. “There have been lots of requests from customers that are really outside of our remit. We keep our focus on what we do best: fresh fruit and vegetables, but we can’t rule everything else out.”