Eindhoven raises the bonnet on DAF's range

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

A °lain man's guide to turbocharged and charge cooled engin

PROBABLY the most vital factor of any transport operation today, be it an owner/operator or a large own account fleet, is "economy of operation" a well worked phrase which can mean everything or nothing. Nothing if it does not work outside the manufacturers glossy brochures but everything if the manufacturer practices what it preaches.

Clearly, economy of operation is influenced by a great many factors, both constants and infinitely variable. Without doubt, the most variable and hence the most vital of these factors is fuel consumption. Initial purchase price, parts cost and supply, repair and maintenance — all of these must be taken into account in calculating the cost of running a vehicle but no one single factor can influence this cost more significantly than fuel economy.

Indeed, a discussion recently with a large DAF fleet operator revealed that variances in driving skills affected fuel consumption on his vehicles by as much'as 8%. In cash terms this is significant. The difference between achieving 8.5m.p.g. and 9.5m.p.g, for example can account for the profit or loss of thousands of pounds.

DAF Trucks claim to have built up a range of quality, economical engines for all types of operation from 16 tons and upwards in the U.K. market. When they started to build engines the first engineering decision was to produce a rationalised range of commercial vehicle diesel engines. As a result, all engines produced by DAF Trucks are six cylinder, inline diesel engines with direct injection.

In more recent years, the range of engine's has been further rationalised to provide two basic engine sizes, (with the exception of the DT 6.17 litre engine). The range now consists of a number of 8.25 and 11.6 litre engines. These are the most flexible sizes for tuning to the light medium / heavy applica tions within the U.K. market. By employing various degrees of turbocharging in the individual series they have developed a range of engines with outputs ranging from 202 b.h.p. to 307 b.h.p.

The 8.25 litre engine comes in a variety of formats from the DH to the DHU, producing from 156 b.h.p. to 230 b.h.p., whereas the 11.6 litre engine may be tuned to produce between 252 b.h.p. and 307 b.h.p. The introduction of the new DKSE engine, the 'economy' version of the DKS, will bring this up to three engine types giving a high torque engine producing 276 b.h.p. The wide variety of engine powers available is obtained by employing natural aspiration and various degrees of turbocharing and turbocharging with intercooling.

Natural aspiration involves the diesel engine pulling in its own air supplied on the induction cycle to produce a low power engine with medium torque characteristics. Incorporating turbocharging in the diesel engine can be done in various -stagesin order to produce different power and torque characteristics. In general, turbocharging produces a medium power and torque characteristics. In general, turbocharging produces a medium power engine with medium to high torque characteristics. Turbocharging and intercooling produces the most efficient form of diesel engine in 'terms of power per gram of fuel used. It produces a high power, 'high torque engine.

The DAF DKS engine is an engine which incorporates both turbocharging and intercooling (charge cooling). Although the 188kW (252 b.h.p.) DKTD would initially seem the natural choice for U.K. operations. Fleet engineers are looking for extra power on the basis that, the more powerful engine will be operating well within its capacity with the consequent benefits in fuel consumption and longevity. To balance this, there are engineers and trans port managers who are still con vinced that around 250 b.h.p. is the optimum for 32-ton opera. tion at least.

The DKTD engine produces 188 kW (252 b.h.p.) at 2,20C r.p.m. and the maximum torque of 881Nm (66011Aft) is developed at 1,500 r.p.m.

The DKS is a more highly rated version of the same 11.6 litre (708cu in) six cylinder engine and it produces a substantial 229kW (307 b.h.p.) at the same maximum speed. The maximum torque of 1,160Nm (855 lbf.ft) is developed at the slightly lower engine speed of 1,450 r.p.m.

With an internal combustion engine, the cooler the air the better from an efficiency and thus economy viewpoint. However, after the air has passed through the turbocharger it is hot, so a system of charge cooling is incorporated in the DKS specification. Once compressed in the turbocharger, the inlet air is passed through an air-to-air charge cooler in the form of an auxiliary radiator mounted ahead of the main water radiator. This arrangement lowers the temperature of the inlet air by approximately 50' C(122c).

DAF claims to be one of the first manufacturers to apply charge cooling to turbocharged engines. Transverse water cooling, in which the coolant flows around the cylinders in a crosswise direction, thus ensuring a uniform cylinder temperature, together with the use of twin thermostats, is another of the design principles which contribute to the economy, reliability and long service life of DAF Trucks' diesel engines.

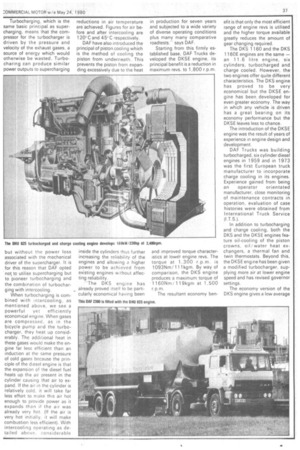

Supercharging is the process by which the air coming into the engine is compressed by mechanical means in order to force more air into the fixed volume of the cylinder. Supercharging greatly increases the engine power but the process of supercharging takes away power from the engine to operate the compressor and is therefore not as efficient as turbocharging. Turbocharging, which is the same basic principal as supercharging, means that the compressor for the turbocharger is driven by the pressure and velocity of the exhaust gases, a source of energy which would otherwise be wasted. Turbocharing can produce similar power outputs to supercharging but without the power loss associated with the mechanical driver of the supercharger. It is for this reason that DAF opted not to utilise supercharging but to pioneer turbocharging and the combination of turbocharging with intercooling.

When turbocharging is combined with intercooling, as mentioned above, we see a

powerful yet efficiently economical engine. When gases are compressed, as in the bicycle pump and the turbocharger, they heat up considerably. The additional heat in these gases would make the engine far less efficient than an induction at the same pressure of cold gases because the principle of the diesel engine is that the expansion of the diesel fuel heats up the aft present in the cylinder causing that air to expand. If the air in the cylinder is relatively cold, It will take far less effort to make this air hot enough to provide power as it expandsthan if the air was already very hot. (If the air is very hot initially, it will make combustion less efficient). With intercooling operating as detailed above, considerable

reductions in air temperature are achieved. Figures for air before and after intercooling are 120°C and 45°C respectively.

DAF have also introduced the principal of piston cooling which is the method of cooling the piston from underneath. This prevents the piston from expanding excessively due to the heat inside the cylinders thus further increasing the reliability of the engines and allowing a higher power to be achieved from existing engines without affecting reliability.

"The DKS engine has already proved itself to be particularly economical having been in production for seven years and subjected to a wide variety of diverse operating conditions plus many many comparative roadtests says DAF.

Starting from this firmly established base, DAF Trucks developed the DKSE engine, its principal benefit is a reduction in maximum revs. to 1,800 r.p.m.

and improved torque characteristics at lower engine revs. The torque at 1,300 r.p.m. is 1093Nm/111kgm. By way of comparison, the DKS engine produces a maximum torque of • 1160Nrn/ 119kgm at 1,500 r.p.m. The resultant economy ben efit is that only the most efficient range of engine revs is utilised and the higher torque available greatly reduces the amount of gear changing required.

The DKS 1160 and the DKS 1160E engines are the same — an 11.6 litre engine, six cylinders, turbocharged and charge cooled. However, the two engines offer quite different characteristics. The DKS engine has proved to be very economical but the DKSE engine has been developed for even greater economy. The way in which anyvehicle is driven has a great bearing on its economy performance but the DKSE leaves less to chance.

The introduction of the DKSE engine was the result of years of experience in engine design and development.

DAF Trucks was building turbocharged, six cylinder diesel engines in 1959 and in 1973 was the first European truck manufacturer to incorporate charge cooling in its engines. Experience gained from being an operator orientated manufacturer, close monitoring of maintenance contracts in operation, evaluation of case histories were obtained from International Truck Service (I.T.S.).

• In addition to turbocharging and charge cooling, both the DKS and the DKSE engines feature oil-cooling of the piston crowns, oil/water heat exchangers, a thermal fan and twin thermostats. Beyond this, the DKSE engine has been given a modified turbocharger, supplying more air at lower engine speed and has revised governor settings.

The economy version of the DKS engine gives a low average piston speed and lower inertia forces on moving parts due to the reduced maximum revs.

However, an economical engine alone is not sufficient to achieve low fuel consumption. It is also necessary to attune the drive-line closely to the engine characteristics. For this reason, the ZF S 130 gear-box is used in conjunction with the new DKSE engine. It is a 16 speed box with double 1-1" shift pattern and ideally suits the characteristics of the new engine. Gear changing is, of course, made easier on the all-synchromesh box enabling more efficient driving particularly in arduous operating conditions. This gearbox is also available as a factory fitted option on the DKS engine.

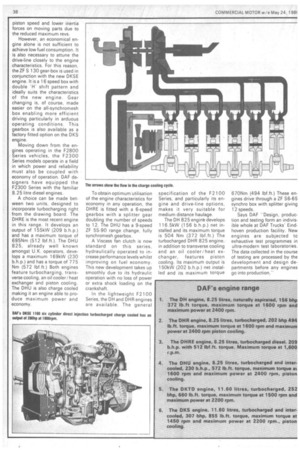

Moving down from the engines operating in the F2800 Series vehicles, the F2300 Series models operate in a field in which power and reliability must also be coupled with economy of operation. DAF designers have equipped the F2300 Series with the familiar 8.25 litre diesel engines.

A choice can be made between two units, designed to incorporate turbocharging right from the drawing board. The DHRE is the most recent engine in this range. It develops an output of 155kW (209 b.h.p.) and has a maximum torque of 695Nm (512 lbf.ft.). The DHU 825, already well known amongst U.K. operators, develops a maximum 169kW (230 b.h.p.) and has a torque of 775 Nm (572 lbf.ft.) Both engines feature turbocharging, transverse cooling, an oil cooler/heat exchanger and piston cooling. The DHU is also charge cooled making it an engine able to produce maximum power and economy. To obtain optimum utilisation of the engine characteristics for economy in any operation, the DHRE is fitted with a 6-speed gearbox with a splitter gear doubling the number of speeds to 12. The DHU has a 9-speed ZF 5S-90 range change, fully synchromesh gearbox.

A Viscass fan clutch is now standard on this series, hydraulically operated to increase performance levels whilst improving on fuel economy. This new development takes up smoothly due to its hydraulic operation with no loss of power or extra shock loading on the crankshaft.

In the lightweight F2100 Series, the DH and DHR engines are available. The general specification of the F2100 Series, and particularly its engine and drive-line options, makes it very suitable for medium distance haulage.

The DH 825 engine develops 1 16.5kW (156 b.h.p.) net installed and its maximum torque is 504 Nm (372 lbf.ft.) The turbocharged DHR 825 engine, in addition to transverse cooling and an oil cooler/heat exchanger, features piston cooling. Its maximum output is 150kW (202 b.h.p.) net installed and its maximum torque 670Nm (494 lbf.ft.) These engines drive through a ZF S6-65 synchro box with splitter giving 12 speeds.

Says DAF "Design, production and testing form an indivisible whole at DAF Trucks' Eindhoven production facility. New engines are subjected to exhaustive test programmes in ultra-modern test laboratories. The data collected in the course of testing are processed by the development and design departments before any engines go into productions"