Ci Ca OMEN'S PE

Page 56

Page 57

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon, A.M.I.R.T.E.

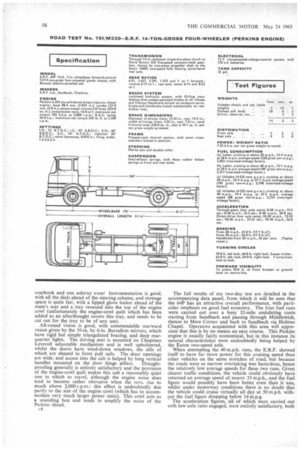

AN operator who is prepared to pay over £2,000 for a 14-ton-gross four-wheeled goods chassis cannot be blamed for expecting for his money a product which is well above the average standard. The purchaser of an E.R.F. 64? will not be disappointed in his buy, particularly outstanding being its fuel economy and its attractive, well laid-out and comfortable cab. Although not cheap—the chassis price is £2,110, plus £300 for the cab—the 64P is well designed and well built, whilst its overall road performance makes it suitable for a wide range of general haulage duties.

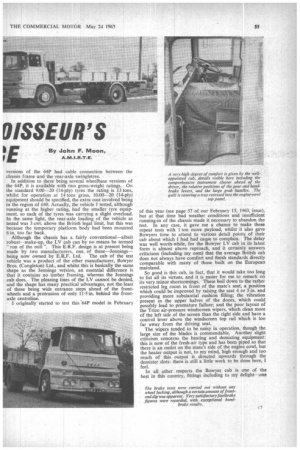

E.R.F. vehicles have for long been renowned for distinctive appearance, and the KV cab, which was introduced towards the end of 1953, has been, to my mind, one of the most attractive heavy-vehicle cabs to have been manufactured in this country. The successor to this cab just had to be at least as attractive and the LV design which is gradually replacing the KV is certainly this. It has the best external appearance of any cab currently being offered as standard on British heavy vehicles, whilst its interior appointments put it well into the Continental " luxury " class. The LV is the sort of cab of which any driver can be proud, and this, in turn, fosters pride in the whole vehicle, resulting in it being well looked after and the driver being content.

So far as road performance is concerned, the 64P, running at well over 14 tons gross, returned 154 m.p.g. at an average speed of 26.6 m.p.h. over a difficult 32-mile route taking in the notorious stretch of A50 between Mere Corner and Holmes Chapel, whilst it confounded the theoreticians by getting half-way up the steep final section of Mow Cop, where the gradient is 1 in 3.75, despite a publicized maximum grade-ability of 1 in +8! Also outstanding was the handbrake retardation, a Tapley-meter reading of 35 per cent being obtained from 20 m.p.h.

As the serial letter " P " suggests, the E.R.F. 64P has a Perkins 6.354 power unit, which is used in its low-rated form and drives through a David Brown 552 direct-top constant-mesh five-speed gearbox. The gearchange lever is remotely mounted to lie approximately beneath the driver's c.6 left elbow: this is farther back than the traditional E.R.F. gear lever position, but it is no less convenient to use, and the new position arises from having moved the handbrake lever forward, where a really good purchase can be obtained on it –hence the good handbrake retardation figure.

The two-piece propeller shaft has a Laynib joint at its forward end and a damper at the rear end, whilst the standard driving axle is an Eaton 16802 two-speed unit with electric shift and ratios of 614 and 8-52 to 1. No single-speed axles are offered, but an Eaton axle with a slightly higher load rating is available as an alternative to the 16802 unit. The ratios of the standard axle, combined with the good spread of the 552 box and the 2,800 r.p.m. top speed of the Perkins engine, give a lively road performance and a maximum of approximately 55 m.p.h.

The chassis-frame side members are 0.25-in. channelsection pressings with an unusual upswept shape, the lower flanges tapering upwards by over 4 in. between the centreline of the front axle and a point approximately mid-wheelbase, the frame depth rearwards of this point being 8 in. The rather high laden frame height of 44 in. resulting from this frame shape and the use of rear springs which lie beneath the frame rather than being outrigged from it, has the advantage of eliminating the need for longitudinal body runners, thereby presenting a weight-saving potential. The single-rate semi-elliptic springs which are used at front and rear have grooved leaves and are supplemented by Aeon rubber auxiliary springs, so that in effect the front and rear suspensions are dual rate. Dampers are not fitted.

Girling two-leading-shoe brakes are used at both axles, these being actuated through a Lockheed hydraulic master cylinder, with boost provided by a Clayton Dewandre Airpak air-pressure servo: this is a true servo, rather than being an air-pressure actuator, so the footbrake pedal is always connected hydraulically to the wheel brakes, thus is not completely worthless in the event of an air pressure failure. The handbrake lever assembly is of E.R.F. design and is linked to the rear brakes through a completely rodded system, a departure from previous E.R.F. practice: original versions of the 64P had cable connection between the chassis frame and the rear-axle swingletree. In addition to there being several wheelbase versions of the 64P, it is available with two gross-weight ratings. On the standard 9.00-20 (14-ply) tyres the rating is 13 tons, whilst for operation at 14 tons gross, 10.00-20 (14-ply) equipment should be specified, the extra cost involved being in the region of £40. Actually, the vehicle I tested, although running at the higher rating, had the smaller tyre equipment, so each of the tyres was carrying a slight overload. In the same light, the rear-axle loading of the vehicle as tested was 3 cwt. above the British legal limit, but this was because the temporary platform body had been mounted 6 in. too far back.

Although the chassis has a fairly conventional—albeit robust--make-up, the LV cab can by no means be termed "run of the mill ". This E.R.F. design is at present being made by two manufacturers, one of these—Jenningsbeing now owned by E.R.F. Ltd. The cab of the test vehicle was a product of the other manufacturer, Bowyer Bros. (Congleton) Ltd., and whilst this is basically the same shape as the Jennings version, an essential difference is that it contains no timber framing, whereas the Jennings cab does. The pleasing lines of the LV cannot be denied, and the shape has many practical advantages, not the least of these being wide entrance steps ahead of the frontwheels and a protrusion of only 11-5 in. behind the frontaxle centreline.

I originally -started to test this .64P model in February of this year (see page 57 of our February 15, 1963, issue), but at that time bad weather conditions and insufficient running-in of the chassis made it necessary to abandon the test. In any case, it gave me a chance to make these repeat tests with 1 ton more payload, whilst it also gave Bowyers time to attend to various detail points of their cab about which I had had cause to complain. The delay was well worth-while, for the Bowyer LV cab in its latest form is almost above reproach, and it certainly answers criticisms (including my own) that the average British cab does not always have comfort and finish standards directly comparable with many of those built on the European mainland.

So good is this cab, in fact, that it would take too long to list all its virtues, and it is easier for me to remark on its very minor shortcomings. These boil down to the rather restricted leg room in front of the mate's seat, a position which could be improved by raising the seat 4 or 5 in. and providing more substantial cushion filling; the vibration present in the upper halves of the doors, which could possibly lead to premature failure; and the poor layout of the Trico air-pressure windscreen wipers, which clean more of the left side of the screen than the right side and have a control lever above the windscreen top rail Which is too far away -from the driving seat. The wipers tended to be noisy in operation, though the large size of the blades is commendable. Another slight criticism concerns the heating and demisting equipment: this is now of the fresh-air type and has been piped so that there is an outlet on the mate's side of the engine cowl, but the heater output is not, to my mind, high enough and too much of this output is directed upwards through the demister slots: there is still a little work to be done here, I feel.

In all other respects the Bowyer cab is one of the best in this country, fittings including to my delight—one coathook and one ashtray even! Instrumentation is good, with all the dials ahead of the steering column, and stowage space is quite fair, with a lipped glove locker ahead of the mate's seat and a tray recessed into the top of the engine cowl (unfortunately the engine-cowl quilt which has been added as an afterthought covers this tray, and needs to be cut out for the tray to be of any use).

All-round vision is good, with commendable rearward vision given by the 10-in. by 6-in. Burrafirm mirrors, which have rigid but simple triangulated bracing, and deep rearquarter lights. The driving seat is mounted on Chapman Leveroll adjustable mechanism and is well upholstered, whilst the doors have wind-down windows, the sills of which are shaped to form pull rails. The door openings are wide, and access into the cab is helped by long vertical

handles mounted on the door hinge pillars. Draughtproofing generally is entirely satisfactory and the provision of the engine-cowl quilt makes this cab a reasonably quiet one in which to travel, although the engine noise does tend to become rather obtrusive when the revs, rise to much above 2,000 r.p.m.: this effect is undoubtedly due partly to the size of the engine cowl (which has to accommodate very much larger power units). This cowl acts as a sounding box and tends to amplify the noise of the Perkins diesel.

The full results of my two-day test are detailed in the accompanying data panel, from which it will be seen that the 64P has an attractive overall performance, with particular emphasis on good fuel economy. The four fuel runs were carried out over a busy 32-mile undulating route starting from Sandbach and passing through Middlewich, thence to Mere Corner and back to Sandbach via Holmes Chapel. Operators acquainted with this area will appreciate that this is by no means an easy course. This Perkins engine is usually fairly economical, but in this instance its natural characteristics were undoubtedly being helped by the Eaton two-speed axle.

When attempting the 40 m.p.h. runs, the E.R.F. showed itself to have far more power for this cruising speed than other vehicles on the same stretches of road, but because the roads were so narrow overtaking was hazardous, hence the relatively low average speeds for these two runs. Given clearer traffic conditions, the vehicle could obviously have returned an average speed of nearer 35 m.p.h., and the fuel figure would possibly have been better even than it was, whilst under motorway conditions there is no doubt that the vehicle could cruise virtually all day at 50 m.p.h. without the fuel figure dropping below 14 m.p.g.

The acceleration figures, all of which were carried out with low axle ratio engaged, were entirely satisfactory, both

through the gears and in top gear. Satisfactory footbrake figures were obtained also, with no wheel locking. Although not quite the best figures obtained with a vehicle of this weight during tests by The Commercial Motor, the stopping distances are still good. The requisite brake pedal effort was on the high side, but this has been done deliberately to reduce the risk of drivers braking excessively hard and so wearing out the brake linings too quickly or getting into trouble when running unladen on slippery_ road surfaces. The efficient handbrake is quite the most powerful single-pull unassisted brake that I have come across so far on a goods vehicle of this weight. Although well beyond the 64P's theoretical performance, I decided to try its paces up Mow Cop, a 0.85-mi1e-long hill with an average gradient of 1 in 9, a section of 1-in-5 half-way up, and a real climax at the very top, where the gradient is 1 in 3-75. The climb was made in an ambient temperature of 16°C. (61°F.), and before making the ascent the engine coolant temperature was recorded as 76°C. (169°F.). Much of the main section of the hill was climbed in bottom-high, though it was necessary to engage low ratio on the 1-in-5 portion and, of course, low was again selected when approaching the 1-in-3.75 stretch.

Unfortunately, this final hump proved a little too much for the hard-working engine, and the vehicle stalled about 40 yd. up the final hump, although an E.R.F. driver had taken this same vehicle right over the top the previous day. The climb was finished after 6.75 minutes, therefore, and the engine coolant's final temperature was 86°C. (187°F.) —a satisfactory low rise for such a gruelling climb. There was no exhaust smoking at any time and bottom-low was engaged for a total time of 2 minutes, with the road speed about 6 m.p.h.

Further proof of the handbrake's effectiveness was its ability to hold the 64P on the 1-in-3.75 section both facing up and down the slope, without having to apply the footbrake first. Mow Cop is a hill to be treated with the greatest of respect, not only because of its steepness, but because the road is narrow and winding, but despite this I decided to try the fade-resistance performance by coasting down the slope at 15 m.p.h., this test lasting 3 minutes 10 seconds, during the whole of which time the footbrake was applied.

Just before the level-crossing at the bottom of the hill I let the speed rise to 20 m.p.h., whereupon I applied the footbrake hard: this produced a Tapley-meter reading of 46 per cent, which indicated that the footbrake efficiency had fallen by only 0-22 g.—and this on a descent for which most drivers would engage second or even bottom gear and crawl down at less than 10 m.p.h.! The brakes had obviously got a lot in hand, for the pedal effort had not risen noticeably; only the offside front brake was smoking, and that only slightly.

Gradient-restart tests were conducted on the 1-in-7.5 slope of Radnor Hill, where an easy reverse-high restart was made while facing down the hill—and—to my surprise —a second-low restart carried out while facing up the hill. This second-low performance again is in excess of that theoretically possible with this vehicle.

As far as general handling is concerned, the 64P rates high marks, The steering is by no means heavy, irrespective of road speed, whilst castor effect is good. The comparatively large number of turns required from lock to lock do not make the vehicle difficult to handle, but on the debit side it was noted that road bumps tended to deflect the steering rather badly at times. Gearchanging is quick and simple, helped by a light clutch which, strange for these days, has mechanical rather than hydraulic actuation, but the gearbox of the particular vehicle I was testing was noisy when in neutral and emitted some rather horrifying vibrations when climbing Mow Cop • on occasions when maximum torque was obviously being put through it.

Laden, the suspension tended to be a bit harsh, and this is probably because the Aeon rubbers were slightly overloaded: indeed, the suspension felt to me to be slightly better when the vehicle was unladen. Under either condition the absence of dampers was in no way harmful, and roll, even when cornering quickly, was virtually negligible.

Despite the length of time spent on the road with the 64P, there was still time for me to carry out a few simple, timed maintenance checks. These included water level (16 sec.), engine oil (55 sec.), gearbox oil (2 min. 15 sec:), axle oil (49 sec.), brake fluid (9 sec.), battery electrolyte (2 mm. 30 sec.), and air-cleaner oil (3 mm. 30 sec.). To check the engine oil it was necessary to raise the cowl top, whilst the short time for checking the brake-fluid level is because the reservoir is mounted on the Lockheed master cylinder, which is on the outside of the right-hand side member, behind the cab.

Other jobs I tackled included changing a fuse in 1 minute and cleaning out the primary filter bowl (and it really needed cleaning too) in well under a minute. There are six fuses in all, the main fuse being housed under a separate cover from the other five, and -all are mounted at an easy working height on the front bulkhead, where they can be reached by opening the bottom-hinged front panel, this being held in place by shooting bolts actuated by a single budget lock. As a final task I removed the spare wheel in 2 min. 15 sec. and restowed it in 1 min. 45 sec.; the 64P has a winch-type carrier operated by the engine cranking handle, and the wheel is secured in place by two nuts on which the wheel-nut box spanner can be used. Generally this E.R.F. appears to be very easy to service, and engine accessibility in particular is very good. The cowl top hinges backwards and can be clipped up against the cab rear panel, whilst the single side panels on each side are quickly detachable and, with these off, the engine is very fully exposed right down to cab-floor level. Because of the large cowl, there is plenty of working room around the Perkins unit.