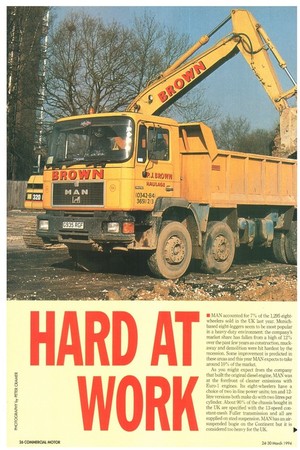

MAN accounted for 7% of the 1,295 eightwheelers sold

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

in the UK last year. Munich based eight-leggers seem to be most popular in a heavy-duty environment: the company's market share has fallen from a high of 12% over the past few years as construction, muckaway and demolition were hit hardest by the recession. Some improvement is predicted in these areas and this year MAN expects to take around 10% of the market

As you might expect from the company that built the original diesel engine, MAN was at the forefront of cleaner emissions with Euro-1 engines. Its eight-wheelers have a choice of two in-line power units; ten and 12litre versions both make do with two litres per cylinder. About 90% of the chassis bought in the UK are specified with the 13-speed constant-mesh Fuller transmission and all are supplied on steel suspension. MAN has an airsuspended bogie on the Continent but it is considered too heavy for the UK.

MAN eightleggers have a reputation for thriving under tough working conditions. Good used examples are commanding a premium price, but are later models better?

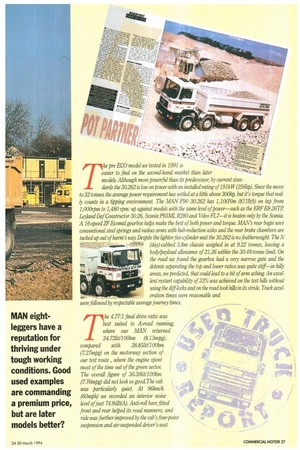

he pre ECO model we tested in 1991 is

easier to find on the second-hand market than later -----""-----141f-Z*;,5,.

models Although more powerful than its predecessor, by current stan

dards the 30.262 is low on power with an installed rating of 191kW (256hp). Since the move to 32 tonnes the average power requirement has settled at a little above 300hp, but it's torque that really counts in a *ping environment. The MAN F90 30.262 has 1,100Nm (811lbft) on tap from 1,000rpm to 1,480 rpm: up against models with the same level of Power—such as the ERF E8-26TR Leyland Daf Constructor 3a26, Scania P93ML R280 and Volvo FL 7—it is beaten only by the Scank A 16-speed 2F Ecomid gearbox helps make the best of both power and torque MAN's rear bogie uses conventional steel springs and radius arms with hub-reduction axles and the rear brake chambers are tucked Hp out of harm's way Despite the lighter five-cylinder unit the 30.262 is no featherweight. The N (day)-cabbed 5.8m chassis weighed in at 9.22 tonnes, leaving a body/payload allowance of 21.26 within the 3048-tonne limit. On the road we found the gearbox had a very narrow gate and the detente separating the top and lower ratios was quite stiff—in hilly areas, we predicted, that could lead to a bit of arm aching An excellent restart capability of 33% was achieved on the test hills without using the diflocles and on the road took hills in its stride Track accet eration times were reasonable and

were followed by respectable average journey times

The 4.77:1 final drive ratio was best suited to A-road running, where our MAN returned 34.731it/100km (8.13mpg), compared with 38.85lit/100km (727mpg) on the motorway section of our test route, where the engine spent most of the time out of the green sector The overall figure of 36.391u/100km (7.76mpg) did not look so good The cab was particularly quiet. At 96Iem/h \ (60mph) we recorded an interior noise level of just 74.9dB(A). Anti-roll bars fitted front and rear helped its road manners, and ride was further improved by the cab's four-point suspension and air-suspended driver's seat. EVOLUTION

MAN'S 30.240 eight-wheeler, on a 6.3m wheel/ base, dates back to January 1984. Its naturally aspirated 11.4-litre engine was rated at 176kW (237hp) and drove through a 400mm clutch to a six-speed, constant-mesh ZF box, In 1986 power was given a boost with chargecooling; capacity was increased to 11.97 litres for the 30.291 and 30.331, which also took the 13-speed Fuller RTO 11613 crash box.

In April 1989 these models were superseded by the F90-cabbed 30.262, 30.292 and 30.332. A charge-cooled 10-litre, five-cylinder unit rated at 191kW (256hp) was introduced for the lower powered model. Both of the more powerful models stayed with the 12-litre unit, still rated at 213 and 242kW (285 and 325hp), but driving through a larger 430nun clutch.

The 30.262 ran through to March 1990 and road speed limiters were introduced to the remaining two models in 1992. That was also the year that operators were given the choice of NIAN's environmentally friendly ECO models in the form of the five-cylinder Euro-1 32.322, rated at 239kW (320hp), and 32.372 six-cylinder model, rated at 276kW (370hp). Both now have a design weight of 32 tonnes.

OPERATORS

Toby Taylor, managing director of bulk earthworks specialist T Taylor (Contractors), operates 34 pieces of plant and 12 tippers within 40 miles of his base at Steeple Claydon, Bucks. He bought his first MAN 30.291 in 1986 and an 30.331 acquired soon after has now covered 540,000 miles. "We were looking to move on from our Magirus tippers and the MANs came along at the right time," says Taylor. "They were more expensive and heavier than the Maggies but they have been very reliable on tipping work. They do a lot of site work with as many as 30 to 40 tips a day. We had a bit of trouble with the early chassis so we !Etched them—we did the same for all our Magirus Deutz. After taking delivery of a new truck it takes about a week to modify it for our use; we fit heavier springs on the rear bogie and lift the exhaust to improve ground clearance.

"Short runs and standing time doesn't do a lot for fuel consumption," he adds, "we get about 6.5mpg. Their one downfall is the chassis weight. We fit Hyva five-stage rams with Thompson steel bodies which leaves us with a payload of 18 tonnes.

"I am looking at increasing our operational weight to 31 tonnes," says Taylor, "but haven't decided yet whether it will be economical for us to go to the full 32 tonnes. We used to change trucks after four or five years but everyone has had to alter their replacement policy over the past few years. People ring us up wanting to buy the next ones due to be replaced. Residuals are very good and they are easy to sell; particularly so if they are only five or six years old. We are beginning to appreciate their long life and are happy to keep them even six or seven years. We are building our own high-tensile steel bodies to replace those we've worn out on the older trucks. The materials are very expensive. We use Domex 690 with Hardox 400 floors and incorporate Autogate's air operated tailgate. At the same time we refurbish them mechanically and they even get a new colour scheme.

"We get through a lot of tyres," he adds. "On site work they don't last long enough to wear out so for the past few years we have fitted pre-cured retreads to the drive axles. They are supplied locally through CTS (Brackley), part of the QA Retreading Group. We are one of the first fleets in the country to use its pre-moulded tyre. Its called the Entyre and uses a contoured tread which also replaces the sidewall veneer. It gives the performance of a precured tread with the looks of a premium beadto-bead remould.

"All of our MANs are 331s and 332s now with the 12-litre six-cylinder engine, which is about as good as there is," he believes. "I've only had two head gaskets go—the Caterpillar engines on the plant give me a lot more trouble."

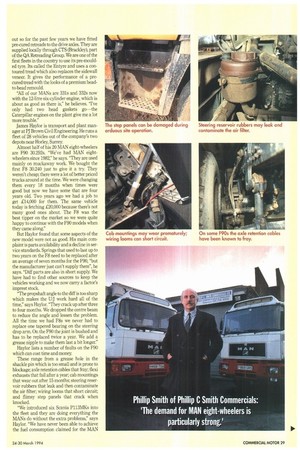

James Haylor is transport and plant manager at PJ Brown Civil Engineering. He runs a fleet of 28 vehicles out of the company's two depots near Horley, Surrey.

Almost half of his 20 MAN eight-wheelers are F90 30.292s. "We've had MAN eightwheelers since 1982," he says. "They are used mainly on muckaway work. We bought the first F8 30.240 just to give it a try. They weren't cheap; there were a lot of better priced trucks around at the time. We were changing them every 18 months when times were good but now we have some that are four years old. Two years ago we had a job to get £14,000 for them. The same vehicle today is fetching £20,000 because there's not many good ones about. The F8 was the best tipper on the market so we were quite happy to continue with the F90 models when they came along."

But Haylor found that some aspects of the new model were not as good. His main complaint is parts availability and a decline in service standards. Springs that used to last up to two years on the F8 need to be replaced after an average of seven months for the F90, "but the manufacturer just can't supply them'', he says. "Diff parts are also in short supply. We have had to find other sources to keep the vehicles working and we now carry a factor's imprest stock.

"The propshaft angle to the diff is too sharp which makes the U/J work hard all of the time." says Haylor. "They crack up after three to four months. We dropped the centre beam to reduce the angle and lessen the problem. All the time we had F8s we never had to replace one tapered bearing on the steering drop arm. On the F90 the joint is bushed and has to be replaced twice a year. We add a grease nipple to make them last a bit longer."

Haylor lists a number of faults on the F90 which can cost time and money.

These range from a grease hole in the shackle pin which is too small and is prone to blockage; axle retention cables that fray; flexi exhausts that fail after a year; cab mountings that wear out after 15 months; steering reservoir rubbers that leak and then contaminate the air filter; wiring looms that short circuit; and flimsy step panels that crack when knocked.

"We introduced six Scania P113MKs into the fleet and they are doing everything the MANs do without the extra problems," says Haylor. "We have never been able to achieve the fuel consumption claimed for the MAN 30.322—the best we got was 5.8mpg (48.7 lit/100km) while the Scanias average between 7.5 and 8.5mpg (37.7 and 33.21it/100km)."

Sheffield Auto Hire has a fleet of 600 vehicles on short and long-term hire. The company runs a mixed fleet of Leyland Daf and MAN eight-wheeled tippers which are equipped with heavy-duty insulated bodies to suit a mixture of work from aggregates to tarmac. General manager Patric Riley runs five MAN 32.322 8x4s that cover about 100,000km a year: "Everything is for sale for the right money from the word go," he says, "but we wouldn't be looking to dispose of them until they have done five years. During their midlife with us we repaint them to keep them looking up to the mark. New prices have gone up a fair lump this year and you can pick them up for £2,000 to £3,000 less than we want for them secondhand, but then we specify different bodies to most other people.

"We try to specify them so that they will take a flap door and barn doors which means two type of mountings at the rear," Riley explains. "Holes in the top rail make it so that greedy boards just slot in. It depends on price as to how easy they are to sell, but people do seem to like MAN eight-wheelers. When I buy a vehicle I look for the best possible deal I can do on the day. MAN is very tight on the warranty with one year on the complete vehicle and secondyear driveline or 100,000miles, where as the competition go to three years on the driveline. The way I look at it, if MAN was confident in its product it would offer the same. We don't have many troubles on the service side but if there is a problem they will talk to you and when the trucks work out of town there are plenty of dealers dotted around to provide the necessary back-up. It's a good driving machine and a good all-round package, but now that Leyland Daf has got its act together with the 85 Series there will be a bit more competition".

DEALERS

Walls Trucks of Newport are one of the more successful MAN dealers in the eight-wheeler market. As well as selling new trucks it normally has 15 to 20 used MAN models in stock. When it comes to warranty Stewart Masterson says: "In special cases I think MAN would extend it to three years if they were asked. The second year is free but you would have to make a contribution towards the third-year cover. But having said that I generally find MAN is quite generous on its policy claims.

"Our prices are not as low as some of the competition," says Masterson, "because the MAN eight-wheeler is a superb vehicle and you get what you pay for. There isn't much that can be added in the way of extras; apart from a stereo they are ready to roll. The residual values are excellent compared with some other makes that are cheaper initially. Operators don't always look at that side of the price equation—they only consider what they are having to pay up front. We get some eight-wheelers back in, but in the main operators tend to hang on to them. Most of the ones we sell locally go on to muck shifting or are used on forestry work. The 12-litre engine is probably the more popular choice and the Eaton box is the best for that type of application. We are fortunate on parts because if we don't have what is needed in stock then we are only three-quarters of an hour down the road from Swindon.

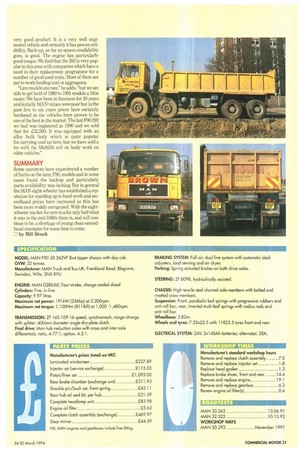

Phillip C Smith Commercials of London Road, Glasgow is one of the largest non-franchise dealers of new and used trucks in the UK, with a stock of some 150 vehicles and 70 trailers. Managing director Phillip Smith says: "The demand for MAN eight-wheelers is particularly strong and has been since the spring of 1993. We have found that there has been a noticeable hardening in the market. We buy nationally but it is difficult to find clean, low-mileage vehicles which have a service history. The vehicle is a very good product. It is a very well engineered vehicle and certainly it has proven reliability. Back-up, as far as spares availability goes, is good. The engine has particularly good torque. We find that the 292 is very popular in this area with companies which have a need in their replacement programme for a number of good used units. Most of them are put to work hauling coal or aggregates.

"Late models are rare." he adds, "but we are able to get hold of 1989 to 1991 models a little easier. We have been in business for 20 years and initially MAN values were poor but in the past five to six years prices have certainly hardened as the vehicles have proven to be one of the best in the market. The last F90 292 we had was registered in 1990 and we sold that for £22,500. It was equipped with an alloy bulk body which is quite popular for carrying coal up here, but we have sold a lot with the Multilift roll on body work on older vehicles."

SUMMARY

Some operators have experienced a number of faults on the later, F90, models and in some cases found the backup and particularly parts availability was lacking. But in general the MAN eight-wheeler has established a reputation for standing up to hard work and secondhand prices have increased as this has been more widely recognised. With the eightwheeler market for new trucks only half what it was in the mid-1980s there is, and will continue to be, a shortage of young clean secondhand examples for some time to come.

71 by Bill Brock