Unique Covering Method

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

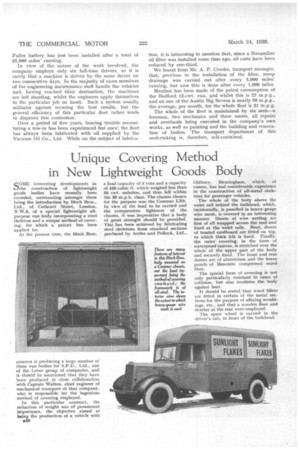

in New Lightweight Goods Body SCOME interesting developments in the construction of lightweight goods bodies have recently been recorded, outstanding amongst them being the introduction by Birch Bros.. Ltd., of Cathcart Street, London, N.W.5, of a special lightweight allpurpose van body incorporating a steel Iceletori and a unique method of covering, for which a patent has been applied for.

At the present time, the Birch Bros.

concern is producing a large number of these van bodies for S.P.D., Ltd., one of the Lever group of companies, and it should be mentioned that they have been produced in close collaboration with Captain Walton, chief engineer of mechanical transport of that company, who is responsible for the ingenious method of covering employed.

In this particular contract, the reduction of weight was of paramount importance, the objective aimed at being the production of a vehicle with BIS a load capacity of 5 tons and a capacity of 450 cubic ft. which weighed less than 50 cwt. unladen, and thus fell within the 30 m.p.h. class. The chassis chosen for the purpose was the Cornrner LN5. In view of the load to be carried and the comparative lightness of the chassis, it was imperative that a body of great strength should be provided. This has been achieved by fabricating steel skeletons from standard sections produced by Accles and Pollock, Ltd,,

Oldbury-, Birmingham, which, of course, has had considerable experience in the construction of all-metal skeletons for passenger vehicles.

The whole of the body above the waist rail behind the bulkhead, which, incidentally, is panelled in heavy-gauge wire mesh, is covered in an interesting manner. Sheets of wire netting are first of all wrapped across the roof and fixed at the waist rails. Next, sheets of treated cardboard are fitted on top, to which thick felt is fixed. Finally, the outer covering, in the form of waterproof canvas, is stretched over the whole of the upper part of the body and securely fixed. The front and rear domes are of aluminium and the lower panels of Masonite compressed wood fibre.

The special form of covering is not only particularly resistant in cases of collision, but also insulates the body against heat. It should be stated that wood fillets are fitted in certain of the metal sections for the purpose of affixing mouldings, etc., and that a wooden floor and shutter at the rear were employed.

The spare wheel is carried in the driver's cab, in front of the bulkhead.