AIDS TO SOLVING FORD PROBLEMS.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase ot Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

1N THIS series of hints concerningthe Ford light chassis and ton truck wherever they are employed tor commercial purposes, we -endeavour; to deal with the subject from every -view-point, so that the advice given will appeal to the owner", driver, maintenance engineer, or mechanic. Valuable sources of information kre being tapped for this purpose, and it should be understood that the information given will be derived from those with an intimate

knowledge of the subject. .

We shall welcome for inclusion. anaiingst the hints those which have proved of value to individual users, and will make suitable remuneration for any published. 'What we desire are the results of practice.

71.—Saving the Commutator Wires.

It will be noticed that the wires of the commutator run directly under the extending .edge of the filler cap, which also serves as a breather for the Crankcase. The constant puffing of hot oily vapour on to the insulation of the wires soon causes this to perish, the rubber often peeling -off and leaving the wire naked, thus causing shorts, usually against the timing cover. Patching up with insulating tape is not a very satisfactory or lasting repair ; besides this, the tape quickly becomes soaked with oil and then comes off. The trouble can be completely overcome by making a tin tube from 4 ins. to 6 ins, long and fastening this to the filler cap. This tube removes the cap to a convenient distance from the wires, and the draught from the fan diverts the downwardly projected vapour to a horizontal direction, and the cap in its new position gets the full benefit of the draught.

Close to its bottom the tin tube should be expanded slightly to form a lip which prevents the tube being inserted too far into the breather orifice.

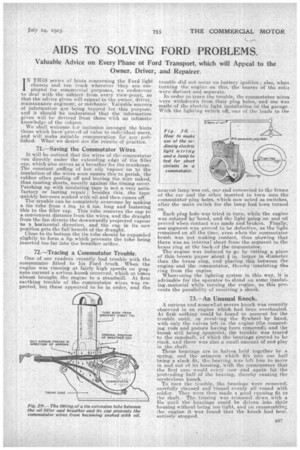

. 72.—Tracing a Commutator Trouble.

One of our readers recently had trouble with the commutator fitted to his Ford truck. When the engine was running at fairly high speeds on viagneto current a serious knock occurred, which at times almost brought the engine to a standstill. . At first earthing trouble of the commutator wires was expected, but these appeared to be in order, and the

trouble did not occur on battery ignition ; also; when turning the engine on this', the buzzes of the coils were distinct and separate.

In order to trace the trouble, the commutator wires were withdrawn from their plug holes, and use was made of the electric light installation in the garage. With the lighting switch off, one of the leads to the nearest lamp was cut, one end connected to the frame of the ear and the other inserted in turn into the commutator plug holes, which now acted as switches; after the main switch for the lamp had been turned on.

Each plug hole was tried in turn, while the engine was yotatedby' hand,and the light going-on and oil: proved when contact was made and broken. Finally; one segment was -proved to be .defective, as the light remained on all the time, even when the commutator brush was not making contact, thus showing that there Was an-internal short from the Segment to the brass ring at the back.of the commutatoa%. The -engine was induced to go by cutting a piece of thin brown paper about in. larger in diameter than the brass ring, and placing this between the engine, and the commutator, thereby' insulating tho "ring from the engine. •

Whenitising the lighting system in this way, it is advisable for the operator to stand on some•insulating.material while turning the engine, as this prevents the possibility of receiving a shock. •

73.--An Unushal'Knock.

A curious and somewhat severe knock was recently observed in an engine which had been overhauled. At first nothing 'could be found to account for the trouble until,' on revolving • the -flywheel by hand, with Only the 'valves left in the engine (the connecting.-rods and pistons having been removed); and the knock still being ,apparent. the trouble was traced to the camshaft, of which the bearings proved to be slack, and there was also a smallamount of end play

in the shaft, These bearings are in halves held together by a spring, and the setscrew which fits into one half being a slack fit, the-bearing was left free to move in and out of its housing, with the consequence that the first cam would every now -and again hit the protruding half of the bearing,_ thereby causing the mysterious knock.

To cure the trouble, the bearings were removed, carefully Cleaned and tinned evenly all round with solder. They Were then made a good running fit to the shaft. The tinning was trimmed -dCwn with a file until the bearings could be driven into their housingwithout being too tight, and on reassembling the engine it Was found that the knock had been entirelystopped.