THE DEMAND FOR BETTER BRAKES.

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

A Criticism of Some Faults and Suggestions for Their. Improvement.

IN THIS • ARTICLE the writer proposes to deal withvehicles of 3-icin .capacity and over ; in • lighter vehicles the .braking question is not so acute. The brakes on heavy petrol lorries are open to criticism from two 'points of view—namely, retardation and the. effort required on the part of the driver. As iil -the case of lighter vehicles, far more attention has been given to the acceleration of heavy lorries than has been devoted to retardation. Acceleration is, of course, a matter of efficient engine and trans-. mission design; retardation is a ' matter of brake design,

The question of retardation is slimmed pp in the 'statement that the maximum retarding force that can act on a vehicle depends upon the load on the braked wheels, and the friction between these wheels and the .road. There is no .practical means 'of increasing this friction temporarily for • braking purposes ; consequently, if brakes are applied to the back wheels only, the retard ing force is only about 60 per cent.

of that which would be available if nil four wheels were utilized. Fur• ey ,t).4p, ther, as was pointed out in an •-..

article which recently appeared in these pages,there are two factors

which tend to increase the load on

the front wheels and reduce that on the rear wheals. These factors

are the downward_ gradient, and and the ''' torque reaction-" or tilting effect produced on a vehicle

which is being pulled up. It The necessary seem:, necessary to emphasize

these important facts, because. many inventors are under themisapprehension that by sufficiently increasing the brake-drum diameter, frietion at the shoes, • and -pressure on the shots) ahy desired retarding foree can be obtained, regardless of the fact that a definite limit is imposed by the axle weight and the friction available between tyre

and road. .

Many people are apt to. criticise British manufacturers for their unwillingness to adopt four-wheel -braking, i3ystems,. se that it may be of interest to recall the fact that over 15, years ago this country led the way in applying this system to a very important type of commercial vehicle—the fire-engine. Unfortunately, several accidents occurred which were traced to the effect of the front-wheel brakes on the steer. ing,.and further work was abandoned owing to official discouragement. french and Italian designers have since carried out a lot of experimental .work on front

wheel brakes, and have brought them to such perfection that the time. now seems ripe for progress on the part of British manufacturers.

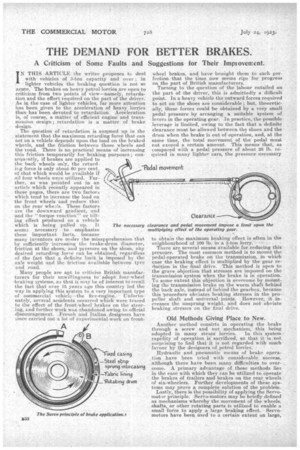

Turning to the question of the labour entailed on the part of the driver, this is admittedly a difficult point. In a heavy vehicle the outward forces required to act on the shoes are considerable ; but, theoretically, these forces could be obtained by a very small pedal pressure by arranging, a suitable system of: levers in the operating gear. In practice, the possible leverage is limited, owing to the fact that a definite clearance must be allowed between the shoes and the drum when the brake is out of operation, and, at the same time, the total movement of the pedal 'MIA not exceed a certain amount. This means that, as compared with a pedal pressure of about N lb. required in many lighter ears, the pressurenecessary

to obtain the maximum braking effect is often in the neighbourhood of 100 lb. in a 3-ton lorry. There are several meanie available forreducing this' pressure. The most common method is to mount the pedal-operated brake on the transmission, in which case the braking effect is multiplied by the gear refluetion in the final drive. This method is open to the grave objection that stresses are imposed on the transmission' system when the brake is in operation. To soine extent this objection is overcome by mounting the transmission brake on the worm shaft behind the back axle, instead of behind the gearbox, because this 'procedure obviates braking Stresses in the propeller shaft and universal -joints. However, it increases the unsprung weight, ahd doe S not obviate braking stresses on the final drive.

Old Methods Giving Place to New.

Another method consists in operating the brake through a screw and nut mechanism, this being adopted in many steam' lorries. In this system rapidity of operation is sacrificed, so that it is, not surmising to fina that it is not regarded with much favour by the designers of petrol lorries. .

Hydraulic and pneumatic means of brake operation have been tried with considerable success, " although there have 'been many difficulties to overcome. A primary advantage of these methods lies in the ease with which they.can be utilized to operate the brakes of trailers and brakes on the rear wheels. of six-wheelers. Further developments of these systems may trove a complete solution of the problem.

Lastly, there is thipoasibility of applying the Servomotar principle. Servo-motors may be briefly defined as mechanisms whereby the movement of the wheels, shafts, or other rotating parts is utilized to enable a small •force, to apply a large braking effect. Servomotors have been used to a certain extent on large,

luxurious types of pleasure car, but the -wide field of application which awaits them in the commercial -vehicle world does not seem to have been generally

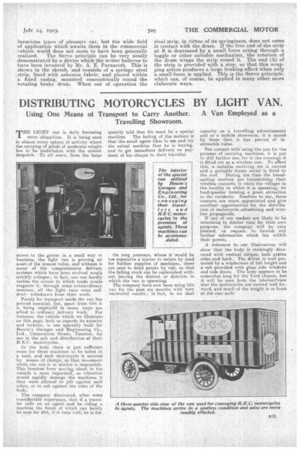

realized. The Servo principle can be very neatly demonstrated by a device which the writer believes to have been invented by Mr. A. E. Parnacott. This is shown in the sketch, and consists of a. springy steel ,strip, lined with a,s-bestos fabric, and placed within a fixed casing, mounted concentrically round the rotating brake drum. When out of operation the

steel strip, in virtue of its springiness, does not come in contact -with the drum. if the free end of the strip at B is depressed by a small force acting through a toggle or other suitable mechanism, the rotation of the drum wraps the strip round it. The end (A) of the strip is provided with a stop, so that this wrapping action produces a large braking effect when only

small force is applied. This is the Servo principle, which can, of course, be applied in many other more elaborate ways.