Late

Page 60

Page 61

Page 62

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

MEE 1ES-BENZ

has I ry and Power

By John F. Moon,

ROAD TEST: Mercedes-Benz LP 1620 32-ton-gross combination AS detailed on page 53, Daimler-Benz A.G. has developed a direct-injection diesel engine for automotive applications, this being the first vehicle diesel without pre-combustion chambers to have been produced by this long-established concern, and the new 10.8-litre engine has been adopted as standard in the LP and LPS 1620 and 1920 ranges of heavy-duty goods chassis which were introduced at the last Frankfurt Motor Show. It was my privilege to be invited to carry out the first Press tests of vehicles fitted with the new unit last autumn, and the four days that I spent working from the Daimler-Benz Gaggenau factory were sufficient to indicate to me that these latest Mercedes-Benz heavyweights are very fine vehicles.

Unfortunately, I have not tested any Mercedes-Benz models with the OM 326 indirect-injection 10.8-litre engine which the new design replaces, and which has been used in the new 1620 and 1920 chassis up until now and in other Mercedes-Benz heavies also. I am unable, therefore, to comment on the performance differences between the OM 326 and OM 346 engines, but I am assured that the new type has decidedly better fuel economy than its predecessor (and figures I obtained showed good economy at 32 metric tons gross train weight), whilst there is ample power to give unusual liveliness in an effortlet, manner at the same train weight.

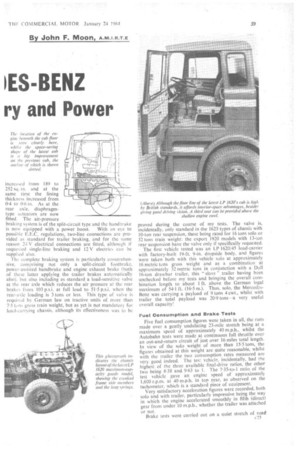

The New Cab Brief details of the new models were contained in my report of the 1963 Frankfurt Show published in our September 20 issue, although at that time the eventual introduction of the direct-injection engine was a well-kept secret. Although mechanically similar to the 334-series vehicles which were introduced in 1961 and went out of production in June of last year, there are certain important differences. By far the most striking of these is the new cab, which Is an all-steel assembly with full forward control: it is located above the engine and so has room for three comfortable seats and two full-size sleeping bunks, and there seems to be little in the way of interior refinements that has been omitted.

At first sight it would appear that submerging the engine u24 beneath the cab floor results in very poor engine accessibility, but further acquaintance with the design shows that there is an entirely adequate number of well-positioned flaps and traps to give good access for routine maintenance, whilst the cab can be lifted off complete in little more than half an hour for more major attention: the electrical side of things is looked after by the provision of four plugs and sockets, the leads to which are all of different lengths so that wrong re-connection is impossible. A particular advantage of the new cab from the operators' angle is that its bumper-to-back-of-cab dimension is only 72.82 in., therefore a 21-ft. body can be mounted on the 14-ft. 9-in.-wheelbase chassis tested, whilst a body of at least 24 ft. 6 in. can be accommodated on the 17-ft.wheelbase model, this latter being available only for export.

In addition to the cab, the many good features of which would occupy far too much space to allow them to be listed here, there have been important mechanical improvements on these new chassis compared with their 334-series predecessors, and these are additional to the adoption of the OM 346 engine. The chassis-frame side members have been increased in section from 9-4 in. by 2.75 in. by 0.25 in. to 9.4 in. by 315 in. by 0.25 in, whilst the frame stiffness in the region of the front axle has been increased. The front and rear springs are nearly 8 in. longer than on the 334, both springs of the new model being 71.5 in. long, with the front springs 3.5 in. wide and the rears 3-9 in.

The front axle has had its track increased by 1.2 in. so that the steering-lock angle could be changed from 42° to 44°, whilst the total front-brake-lining area has been increased from 189 to 252 sq. in. and at the same time the lining thickness increased from 0-4 to 0-6 in. As at the rear axle, diaphragmtype actuators are now fitted. The air-pressure braking system is of the split-circuit type and the handbrake is now equipped with a power boost. With an eye to possible E.E.C. regulations, two-line connections are provided as standard for trailer braking, and for the same reason 24 V electrical connections are fitted, althoueh if requested single-line braking and 12 V electrics can he supplied also.

The complete braking system is particularly comprehensive, comprising not only a split-circuit footbrake. power-assisted handbrake and engine exhaust brake (both of these latter applying the trailer brakes automatically also). but also including as standard a load-sensitive valve at the rear axle which reduces the air pressure at the rear brakes from 103 p.s.i. at full load to 51-5 psi. when the rear-axle loading is 3 tons or less. This type of valve is required by German law on tractive units of more than 7.5 tons gross train weight, but as yet is not mandatory for load-carrying chassis, although its effectiveness was to be proved during the course of my tests. The valve is, incidentally, only standard in the 1620 types of chassis with 10-ton rear suspension, these being rated for 16 tons solo or 32 tons train weight: the export 1920 models with 13-ton rear suspension have the valve only if specifically requested.

The first vehicle tested was an LP 1620/45 load-carrier with factory-built 19-ft. 9-in. dropside body, and figures were taken both with this vehicle solo at approximately 16 metric tons gross weight and as a combination at approximately 32 metric tons in conjunction with a Doll 16-ton drawbar trailer, this " slave " trailer having been unchecked before my tests and bringing the overall combination length to about 1 ft. above the German legal maximum of 54-1 ft. (16-5 m.). Thus, solo, the MercedesBenz was carrying a payload of 9 tons 4 cwt., whilst with trailer the total payload was 20-9 tons--a very useful overall capacity!

Fuel Consumption and Brake.Tests Five fuel consumption figures were taken in all, the runs made over a gently undulating 23-mile stretch being at a maximum speed of approximately 40 m.p.h., whilst the Autobahn tests were made at continuous full throttle over an out-and-return circuit of just over 16 miles total length. In view of the solo weight of more than 15-5 tons, the figures obtained at this weight are quite reasonable, whilst with the trailer the two consumption rates measured are very good indeed. The test vehicle, incidentally, had the highest of the three available final-drive ratios, the other two being 8-38 and 9.63 to I. The 7-35-to-1 ratio of the test vehicle gave an engine speed of approximately 1.600 r.p.m. at 40 m.p.h. in too gear, as observed on the tachometer, which is a standard piece of equipment. Very satisfactory acceleration figures were recorded, both solo and with trailer, particularly impressive being the way in which the engine accelerated smoothly in fifth (direct) gear from under 10 m.p.h.. whether the trailer was attached or not. Brake tests were carried out on a Quiet stretch of road near Jffezheim, and during both the solo and combination tests all the stops were made without any wheel locking or instability, the measured stopping distances being entirely acceptable. The single-line air-pressure system was used for the trailer brakes, although twin-line connections were fitted on both parts of the combination, and the effect of the trailer brakes can be-seen by the higher Tapley-meter readings obtained with the trailer attached when making the handbrake tests from 20 m.p.h. Towards the end of my period with this vehicle, some solo crash " stops were made in the unladen condition on a wet piece of road, and the effectiveness of the load-sensitive valve was shown by the continued absence of wneel locking under these adverse conditions.

All the gradient-performance tests were carried out on Wolfslucht Strasse, Baden-Baden, the average slope of this hill being 1 in II, whilst the length is 1-25 miles. Runs were made with the trailer attached first, and in an ambient temperature of 12°C. (54°F.) a fast non-stop ascent was completed in the good time of 11 min., this causing the engine-coolant temperature (as measured at the cylinder head) to rise from 76'C. (169'F.) to only (176F.. Bottom gear was engaged for a total time of 7 min. 15 sec., and the minimum speed was about 4 m.p.h., corresponding to an engine speed of approximately 1,200 r.p.m.----which is close to the speed at which maximum torque is given. No exhaust smoking was observed during this ascent. It goes without saying that the outfit was not coasted down the Wolfslueht in neutral to check fade resistance (apart from anything else, such a practice is illegal in Germany), but the effectiveness of the exhaust brake was proved by descending the hill without use of the footbrake in 10 min.

Solo, the LP 1620 made the ascent in 5 min. 19 sec., the minimum speed being 10 m.p.h. and the lowest gear used being second, which was employed for only I min. 6 sec. The coolant temperature rose from 74°C. (165'F.) to 78-C. (172 F.) as a result of this fast climb, showing that the engine hardly noticed the extra work! Without the trailer a fade test was made, and this was done in neutral at about 20 m.p.h.: the descent lasted for 3 min. 54 sec., and at the bottom of the hill a " crash " stop produced a Tapley-meter figure of 79 per cent, which was only 12 percent less than that obtained from 20 m.p.h. when the drums were cold. The air pressure stayed up well throughout this test, and a line pressure of only 21 p.s.i. was used most of the time.

The maximum gradient on the Wolfslucht is 1 in 6.7, and on this slope the towing-vehicle handbrake held the outfit easily facing either way.. A bottom-gear restart was shown to be just possible, although it was not easy to avoid clutch -slip, whilst facing down the hill I was unable to reverse the outfit because of clutch slip, and I could not help feeling that perhaps the clutch was not big enough. Solo restarts were made in second and reverse with the greatest of ease.

Both laden and unladen, with and without trailer, the Mercedes-Benz LP 1620 is a delightful vehicle to drive and reaches the highest standards yet set in Europe. The engine pulls well even at the maximum train weight, and very little of its noise reaches the occupants of the cab. The Z.E. box is simple to use and the clutch is light to actuate as a result of an assist spring in the linkage. The gearing suits the engine's power characteristics admirably, and speedometer readings taken in each of the gears indicated respective speeds of 6, .10-5, 17, 26, 40 and 56 m.p.h.: if the engine revs are allowed to go up to the maximum between each change, the ratio-spread is such that the speed of the crankshaft does not fall below 1,600 r.p.m. when the next highest gear is engaged, and this makes for smooth and powerful acceleration at all times.

The ride is remarkably good irrespective of load, but while driving I was always conscious of a certain amount of trailer tugging -even at steady speeds—and this effect must also surely tend to raise the fuel-consumption rate compared with, say, an articulated outfit running at the same weight. No road shocks were transmitted to the steering at any time and the steering itself was beyond reproach, with no tendency to wander, entirely adequate castor effect and progressive servo take-up. The steeringwheel position is good relative to the driving seat—the same can be said of all the controls, in fact—whilst the driving seat is extremely comfortable and fully adjustable. The cab rear mounting consists of the usual Mercedes-Benz damped transverse leaf spring. Because of the cab's high floorlinc, the all-round range of vision is good except for a blind spot in the right-hand rear corner (where there is no glazing because of the bunk beds), and the high seating position helps to cut down dazzle from oncoming traffic also: bad-weather vision is helped by the provision of triple windscreen wipers and twin washers as standard.

Fully Equipped Cab The cab is very fully equipped for long-distanee operations and its finish is comparable with that of Mercedes-Benz private cars. A tremendous amount of attention to detail is evident and standard fittings include a large two-way roof vent and a 6-5 kW. fresh-air heating and demisting set. There are plenty of grab handles to assist getting into and out of the cab, and the entrance steps are ahead of the front wheels, as demanded by German law. Stowage accommodation is generous, and the glove locker in the dash even incorporates an interior light.

Maintenance of the engine is not as difficult as it looks. The front cowl panel hinges up to give access to the fan belt and leading four cylinder heads, the other heads being accessible through the rear half of the cowl. The batteries are housed beneath the folding lower bunk, whilst the radiator and heater are reached through the front grille panel. to each side of which are smaller traps giving access to the steering gear and servo-fluid reservoir on one side and the dipstick and oil filler on the other. Raising the front-step assembly on the left side gives access to the starter motor and generator in addition to that side of the engine, whilst the right-hand steps trap gives access to the injection pump, filters, air compressor and so forth. The Mercedes-Benz LP 1620 load-carrier has a distinctive appearance which its quality and performance live up to admirably. It is the result of Daimler-Benz's long experience in the field of heavy goods transport and should find wide appeal in its country of origin as well as outside Germany. With the OM 346 engine, the chassis-only price is 46.700 D. Marks (approximately £4,700), and the cab is priced at 5,800 D. Marks (£520); the timber-built body as fitted to the test 'vehicle cost 2,500 D. Marks (£225). These prices are 650 D. Marks (£58) more than for the griginal models with OM 326 engine. Right-hand drive is available only on 1920-series export chassis.

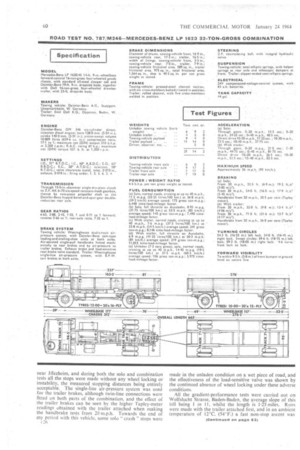

Specification

MODEL Mercedes-Benz LP 1620/45 14-ft. 9-m.-wheelbase forward-control 16-ton-gross four-wheeled goods chassis, with standard all-steel sleeper cab and Daimler-Benz 19-ft, 9-in. dronside body, together with Doll 16-ton-gross four-wheeled drawbar trailer, with 23-ft. dropside body.

MAKERS

Towing vehicle: Daimler-Ben-1 A.G.. Stuttgart. Untertiirkheim, W. Germany.

Trailer; Enid Doll KG., Oppenau, Baden, W. Germany.

ENGINE

Daimler-Benz ON 346 six-cylinder directinjection diesel engine; bore 128.0 mm. (5.04 in.); stroke 140.0 mm. (5.51 In.); piston-swept volume 10.809 litres (659.6 cu. cn.); compression ratio, 17.1 to 1; maximum net (DIN) Output 210 b.h.p. ar 2,200 r.p.m.; R.A.C. racing 61 h.p.; maximum net (DIN) torque .521 b. ft. at 1,300 r.p.m.

SETTINGS 1.0., 31° B.T.D.C.; IC., 60° A.B.D.C.; E.O., 65' B.B.D.C.; EC., 28° A.T.D.C.: injection, 18° B.T.D.C.; valve clearances (cold), inlet, 0.010 in., exhaust, 0.018 in.: firing order, 1. 5. 3. 6. 2. 4.

TRANSMISSION Through 15-0-in.-diameter single-dry-place clutch to Z.F. AK 6-70 six-speed constant-Mesh gearbox, thence by two-piece propeller shaft to the Daimler-Benz hypoid-bevel-and-spur-gear doublereduction rear axle.

GEAR RATIOS 6-63, 3.88, 243, 1-55, 1 and 0-71 to 1 forward; reverse 5.66 to 1; rear-axle ratio, 7.35 to 1.

BRAKE SYSTEM Towing vehicle: Westinghouse dual-circuit airpressure system, with Daimler-Benz cam-type leading-and-trailing-shoe units at both axles. Air-assisted single-pull handbrake linked mechanically to rear brakes and by air-pressure to trailer brakes. Exhaust brake and load-sensitive rear-brake valve standard. Trailer: Westinghouse single-line air-pressure system. with B.P.W. cam brakes at both axles. BRAKE DIMENSIONS • Diameter of drums, towing-vehicle front, 16.9 in., towing-vehicle rear, 17-3 in.; trailer, 16.5 in.; width of linings, towing-vehicle front, 5.5 in., towing-vehicle rear, TO in., trailer, 7.9 in.; towing-vehicle frictional area, 589 sq. in,, trailer frictional area, 975 sq. in., total frictional area, 1,564 sq. in., that is 49.5 sq. in. per ton -gross • waight as tested.

FRAME Towing-vehicle: pressed-steel channel section, with six cross-members bolted/riveted in position. Trailer: rolled channel, with five crass-rnern hers welded in position. STEERING Z.F. recirculating ball, with integral hydraulic ,SUSPENSION Towing-vehicle: semi-elliptic springs, with helper springs at rear axle and telescopic dampers at front. Trailer: slipper-ended semi-elliptic springs.

ELECTRICAL 24V compensated-voltage-control system, with 83 a.h. batteries.

TANK CAPACITY . 44 gal.

Test Figures I

FUEL CONSUMPTION (a) Solo, normal roads, cruising at up to 40 m.p.h., 111 m.p.g. (25-25 litres/100 km.) at 36-8 m.p.h. (59-2 km/h) average speed: 175 gross ton-m.p.g.; 6,440 time-load-mileage factor. (b) Solo, full throttle on Autobahn, 8.95 m.p.g. (31-75 litres/100 km.) at 53.5 m.p.h. (135 km/h.) average speed: 140 gross ton-m.p.g.; 7,490 timeload-mileage factor.

(c) With trailer, normal roads, cruising at up to 40 m.p.h., 7.6 m.p.g. (37.3 litres/100 km.) at ' 33-8 m.p.h. (54-5 km/h.) average speed: 241 gross ton-m.p.g.; 8,146 time-load-mileage factor.

(d) With trailer, full throttle on Autobahn, 6.9 m.p.g. (41.25 litres/100 km.) at 50.3 m.p.h.' (81 km/h.) average speed: 219 gross ton-m.p.g.; 11,015 time-load-mileage factor.

(e) Unladen (7.3 tons gross), solo, normal roads, cruising at up co 40 m.p.h., 14-45 m.p.g. (19.5 litres/100 km.) at 37-5 m.p.h. (60-3 average speed: 106 gross ton-m.p.g.; 3,975 timeload-mileage factor. ACCELERATION (a) Solo:

Through gears, 0-20 m.p.h., 13.5 sec.; 0-30 m.p.h., 24.25 sec..' 0-40 m.p.h., 40.5 sec.

Direct drive 10-20 m.p.h., 11.25 sec;; 10-30 m.p.h., 22.5 sec.; 10-40 m.p.h., 37-75 set.

(b) With trader: • Through gears, 0-7.0 m.p.g., 21-5 sec.; 0-30 _m.p.h., 44.75 sec.; 0-40 m.p.h„ 81-75 sec. Direct drive 10-20 m.p.h., 26.5 sec.; 10-30 m.p.h.,.52-5 sec.; 10-40 m.p.h., 82.5 sec.

MAXIMUM SPEED

Approximately 56 m.p.h., (90 km/h.).

BRAKING (a) Solo: From .2.0 m.p.h., 22.5 ft. (6-9 m.): 19.2 it./s' (5-85 m/0).

From 30 m.p.h., 5+0 ft. (16.5 m,): 17.9 ft./s2 (5-45 m/s').

Handbrake from 20 m.p.h., 30.5 per cent (Tapley meter).

(b) With trailer: From 20 m,p.h., 32.0 'ft. (9.8 m.):. 13-4 (4.06 mis'). from 30 m.p.h., 71-0 ft. (21-6 m.): 13.7 ft./0 (4.17 mls'). Handbrake from 20 m.p.h., 36.0 per cent (Tapley meter). .

TURNING CIRCLES

5+3 ft. (16.55 m.) left lock, 5+0 ft. (1-45 .m.) right lock. Swept circles: 59-6 ft. ('1815 m.) left lock. 59.3 ft. (18.05 m.) right lock. -4-6 turns.'

from lock to lock. • FORWARD VISIBILITY To within 9-2 ft. (2-8 rn,) of front bumper at ground level on centre fine.