WHERE THE STEAMER GETS THE PULL.

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

"A Petrol Engine Stopped is Dead : A Steam Engine May be Exerting Its Maximum Power When Stationary," Says a Writer Who Here Favours the Steam Wagon.

IN an earlier article, which appeared on page 658 of The Commercial Motor for December 20th, I remarked on the unchallenged supremacy of the steam wagon as compared with the petrol vehicle when really heavy work had to be done. In particular I pointed out the striking difference in performance between the two types, exemplified when, for some reason or other, the wagon had got into a hole or was in some place whence it was 'lifficult to emerge. I showed in part that this was due to the fundamental difference in operation of the two machines, in that while a petrol engine when stopped is inert and useless, a steam engine may be stationary yet at the same time be exerting an enormous pull.

A Startling Assertion.

This assertion will probably be found hard of acceptance by many, even by those well acquainted as users with both types—those who have perhaps observed the difference in operation of the two types of vehicle in the circumstances named but who have no real idea why that reason exists and who have not been able to discover it.

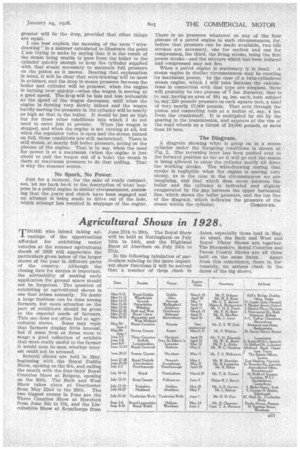

As a preliminary to proving this statement, I showed in that first article the way in which a petrol .engine operates. Knowledge of that in a more or less superficial form is fairly widespread to-day, and it might have been thought unnecessary to enlarge upon it. I wanted, however, to make sure that that knowledge was precise and not, as is, I am afraid, the case with the majority of people, somewhat nebulous and hazy. It was essential to have that exact knowledge in order to make fair and more or less accurate comparisons possible. To facilittite the understanding of the textual description of that operation a diagram accompanied the article, showing the rise and fall in pressure of the gases within the cylinder of an internal-combustion engine during the four strokes familiarly known as suction, compression, firing and exhaust. That diagram is reproduced herewith for purposes of comparison with the steam-engine diagram to which reference will be made a little later.

Steam and Internal-combustion Cycles of Operation.

The diagram relating to the petrol engine has to be arranged to illustrate four strokes of the piston because those four strokes are necessary in order to complete the cycle of operations as enumerated above. In a B30 steam engine only twostrokes need thus be illustrated : the power stroke and the exhaust stroke, the cycle of operations within the cylinder of a steam engine being completed in those two. In a four-cylindered petrol engine there are two power strokes per revolution. The same number of power strokes is available for the same period in a single-cylindered, double-acting steam engine—and most steam-wagon engines are doubleacting, that is to say, the steam is admitted alternately to both sides of the piston.

As every steam wagon has two cylinders, it follows that there are twice as many power strokes per revolution to a steam engine as there are to that of a fourcylindered petrol engine, which is the type most often used to-day on commercial vehicles. The steam engine, consequently, has twice as many power strokes as the petrol and the pressure which is transferred to the driving wheels is therefore, flywheel apart, more even and continuous in the steam wagon than in the other. In that fact alone lies one reason why the steam wagon has the advantage in the circumstances we have been considering. The crankshaft of a steam engine is always subject to steam pressure acting through its piston rod, except when the reversing lever is linked up almost tc its mid position, and that only happens at the wish of its driver and when the demand for power is negligible.

The Working Pressure of the Steam.

Before going on to the description of the operation of the steam in the cylinder I must first clear up a point which is not properly understood even by many

who consider themselves to he fairly well acquainted with a steamer. The pressure of the steam in the eylinder. of the engine is not always that which is shown on the steam gauge. The latter indicates the pressure in the boiler. There is a drop between the boiler and the cylinder. Its extent depends on conditions of design and construction, the speed at which the engine is running and the care with which the wagon is maintained". Some a these conditions I shall consider in a later article. Just now I am only concerned with those which induce what is called "wiredrawing," and that is the fall in pressure which is brought about by.the steam having to pass through the pipe between the boiler and the engine and through the ports by which it enters the cylinder. The smaller and longer the pipe and the smaller the ports the

greater will be the drop, provided that other things are equal.

I can best explain the meaning of the term " wiredrawing" in a manner calculated to illustrate the point I am trying to make by saying that it is the result of the steam being unable to pass from the boiler to the cylinder quickly enough to keep the cylinder supplied with that steam necessary to maintain full pressure on the piston as it moves. Bearing that explanation in mind, it will be clear that wire-drawing will be most in evidence, and the drop in steam pressure between the boiler and cylinder will be greatest, when the engine is turning over quickly—when the wagon is moving at a good speed. The drop will be less and less noticeable as the speed of the wagon decreases, until when the engine is turning very slowly indeed and the wagon hardly moving the pressure in the cylinder will be nearly as high as that in the boiler. It would be just as high but for those other conditions into which I do not need to enter just at present. When the wagon is stopped, and when the engine is not turning at all, but when the regulator valve is open and the steam turned on full, those conditions are still maintained. There is still steam, at nearly full boiler pressure, acting on the pistons of the engine. That is to say, when the need for power is at a maximum (when the engine is just about to pull the wagon out of a hole) the steam is there at maximum pressure to do that pulling. That is why the steamer scores.

No Spark, No Power.

Just for a moment, for the sake of ready compari-. son, let me hark back to the description of what happens in a petrol engine in similar circumstances, assunaing that the gears and clutch have been engaged and an attempt is being made to drive out of the hole, which attempt has resulted in stoppage of the engine. There is no pressure whatever on any of the four pistons of a petrol engine ia such circumstances, for, before that pressure can be made available, two idle strokes are necessary, one for suction and one for compression, the third, the firing stroke, being the first power stroke—and the mixture which has been induced and compressed may not fire.

When a petrol engine is stationary it is dead. A steam engine in similar circumstances May be exerting its maximum power. In the case of a twin-cylindered steam engine, which I will take because the calculations in connection with that type are simplest, there will probably be two pistons of 7 ins, diameter, that is to say, havingun area of 38-i sq. ins. each, both subject te, say, 220 pounds pressure on each square inch, a total of verynearly 17,000 pounds. That acts through the piston and connecting rods at a radius of, say, 4 ins. from the crankshaft. It is multiplied by six by the gearing in the transmission, and appears at the rim of the road wheels as a thrust of 24,000 pounds, or more than 10 tons.

The Diagram.

• A diagram showing what is going on in a steam cylinder under the foregoing conditions is shown at Fig. 2. The reversing lever has been pushed over to the forward position as far as it will go and the steam is being allowed to enter the cylinder neatly all down the working stroke. The wire-drawing during that stroke is negligible when the engine is moving very slowly, as is the case in the circumstances we are imagining, and that which does occur. between the boiler and the cylinder is indicated and slightly exaggerated by the gap between the upper horizontal line, which shows the boiler pressure, and the top line of the diagram, which indicates the pressure of the steam within the cylinder. COMPOUND.