RUNNING PETROL I ES ON HEAVY OIL.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

!THE ORDINARY type of petrol engine, as

applied to the commercial vehicle, is, in its present state, almost entirely dependent for its fuel supply on the lighter fractions resulting from the distillation or cracking of heavy oils and having a sp. gr. pot greater than .760. The result is that there is an intensified demand upon fuels which form a comparatively small proportion of the total output of crude oil, and as this demand is steadily increasing, and there is, in some quarters, a constant fear that the sources of supply may eventually diminish in number, the average price seldom remains stable for more than a few months, and lately has had a decided tendency to rise.

Various attempts have been made to modify the petrol engine so that it would be capable of running satisfactorily on the heavier constituents, but so. far very little success has been achieved in this direction, except in marine work, where weight is not a matter of the greatest importance, and where the engines do not have to possess the same degree of flexibility as is desirable—and, in fact, essential—in the power units of road transport vehicles.

The chief difficulties have been due to recondensabon of the vaporized, or partially vaporized, fuel in the air-fuel mixture, this resulting in dilution of the lubricating oil, with the consequent evil effects of undue wear on the bearings and sometimes seizures, unless the oil be constantly changed. In many cases, due to defective carburation, there were excessive deposits of carbon, necessitating constant cleaning of the cylinders, pistons, etc. ; in fact, taken altogether, many users consider that "the game is not worth the candle," as the increase in the consumption of oil and the extra work required in maintenance more than offset any gain through reduced fuel cost.

It must. not be thought, however, that we place all the devices for permitting the use of paraffin into the same category. Two or three have been devised which give very satisfactory running on paraffin, and in at least one type we believe that no trouble through crankcase condensation has been experienced. However, in this article we are dealing more particularly with the possibility of employing fuels far heavier than the ordinary grade of paraffin—in other words, gag oils and Diesel oils ranging from .880 sp. gr. to .900 sp. gr., and which hitherto it has only been possible to employ with any considerable measure of success in Diesel and semi-Diesel engines in which

B32 high compression is always embodied.

If such fuels could be utilized with success on the average commercial vehicle' a great vista of possibilities would be open to us, and the range of fuels would at once be increased to a remarkable degree. We may consider that approximately 75 per cent. of the whole of the petrol used in this country is consumed by the engines of commercial vehicles, and if a considerable portion of this could be saved it would, as an incidental, have an immediate tendency to cheapen the petrol employed for private uses, or on the smaller types of commercial vehicle where the fuel consumed is not sufficient to justify radical alterations in power units.

Oils of the sp. gr. mentioned can be purchased at from 40. to 6d. per gallon, which is approximately onethird of the cost of petrol. There should be no difficulty in the supply, as it is not a matter of vital importance to the oil companies whether they obtain their profit from the sale of crude oil or refined spirit, and the crude oil must always necessarily be much cheaper because of the saving in the refining and the considerable reduction in wastage, for it is well known that in the case of the lighter fractions of petroleum this wastage is considerable. Apart from this, the fire risks are also reduced to a great extent, and it is a fact that fires can even be choked out by the use of heavy oil. This question of fire risk and insurance would also apply to vehicles employing the heavier oils. From the national point of view we must always consider the extreme danger to our transport arrangements if we are ever cut off from our external sources of supply, and we may point out in this connection that we have in this country quantities of shale oil from which gas oil of a good quality can be obtained. Incidentally, it may be raentionbd at this point that the best oils for use in low-compression engines are those having a low paraffin-wax content, as this wax is apt to cause pinking at low engine speeds., and here shale oil shows its value as it contains no paraffin-wax at all.

It may surprise many of our readers to know that for some 18 months past roadtransport vehicles with power units of the ordinary petrol type have been running on gas and Diesel oils in Italy, and have given some very successful re suits, so reliable have they proved, indeed, that they are now being employed for carrying the Royal Mails. In addition, the Michelin Co., of Turin, have been running a fleet of vehicles on gas oil of .880 sp. gr. to .890 sp. gr. between Turin and Valle di Susa, using petrol for starting purposes.

The figures obtained in the use of one of these vehicles, consisting of an 18 B.L. Fiat lorry with trailer, are of startling interest. Running on petrol only, this vehicle cost .527d. per ton-mile for fuel; with a mixture of one-third petrol and two-thirds paraffin, the fuel cost was reduced to .412d. per ton-mile, but when arranged for utilizing gas oil, the cost was reduced to .188d. per tonmile in the month of March, which was reduced steadily to .163d. in the month of June the costs being based on petrol at ls. 3d. per gallon and gas oil at 6d. per gallon. It will thus be seen that the cost, when using gas oil, was only one-third of that when using petrol only. The apparatus used for the purpose is known in Italy as the "Naftoil," but in this country is designated the " Vapour Oil," the concessionnaires being the Vapour Oil Co., Ltd. 2 and 3, Duke Street, St. James's, Ltd., S.W.1.

It is desirable to emphasizehere that the system is primarily designed for incorporation during manufacture, and if embodied in this manner adtls but little to the first cost, except that a second carburetter of ordinary type is required.

However, to assist those users who are particularly desirous of adapting their engines for heavy °ill a series of standard castings for individual existing engines is being developed.

The Vapour Oil construction involves minor alterations in the design of the cylinder head castings, these castings being's arranged with suitable ports chambers f or the oil "boilers," or vaporizers, and leads from the carburetters, but no alterations are made to the stroke, the cycle of operations or the compression, and th e monobloc head with the heavy-oil carburetter, that for petrol and the connections simply go into place, connect up to the standard controls and the device is ready for service, providing that the tanks for petrol and heavy oil respectively are in position.

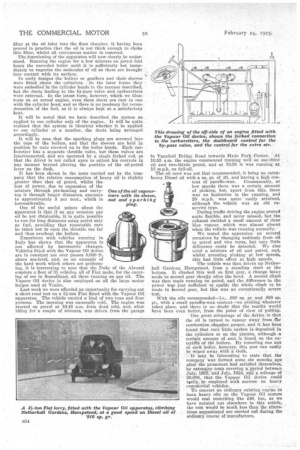

The Vapour Oil system has the great advantage of simplicity. To obtain a clear understanding of the arrangement, it will be advisable for the reader closely to examine the line and half-tone illustrations accompanying this matter. It will be seen that above each cylinder is a large socket, almost equal in bore to that of the cylinder, and into it is screwed a hollow steel member which is known as the boiler. This member is not watercooled, and surrounding it is a sleeve provided at its upper circumference with a piston ring and with a skirt which fits fairly closely round the bottom of the boiler, and enters what may be termed the boiler trough. A port in this sleeve puts it into direct communication, through a duct in the cylinder-head casting, with the oil carburetter. ' In the inlet pipe of the lower, or petrol carburetter, is a barrel by-pass valve, and, when this valve is turned to the petrol position, the petrol carburetter is in direct communication with the duct leading to the inlet valve. When, however, the by-pass barrel is rotated to the Vapour Oil position, the inlet duct is placed into communication with the exterior of the sleeve surrounding the boiler, and the mixture of air and minute globules of oil is sucked into the sleeve, down the sides of the boiler, under the skirt of the sleeve, through a subsidiary duct leading to the by-pass valve, and thence to the inlet valve.

We have already alluded to the fact that petrol is employed for starting purposes. To effect this, the lever on the-dash by which the by-pass valve is controlled is turned to petrol and the engine started. It can then be driven straight away, using petrol only, and after a few minutes, when the temperature of the cooling water has reached from 105 degrees F. to 125 degrees F. (which usually means a running distance of only a few hundred yards), the lever is turned to a position about midway between the petrol and oil. By this means the vapour drawn into the combustion chamber is a mixture of petrol, oil vapour and air, and, if the engine continues to function satisfactorily with the lever in this position, it is turned to the full-oil position, in which the petrol carburetter is entirely out of action. If necessary, an extraair inlet can also be opened. The two carburetters are practically identical. In the apparatus we inspected they were of Solex make, and in the case of the device as fitted to the 311i-ton Fiat, the petrol jet was .135 rum. and the jet for gas oil .140 mm., but, in addition, a smaller choke tube was fitted for the heavy-oil jet, and a special

filter at the oil inlet into the float chamber, it having been proved in practice that the oil is not thick enough to choke this filter, whilst all extraneous matter is removed.

The functioning of the apparatus will now clearly_he understood. Running the engine for a few minutes an petrol fuel heats the uncooled holler until it is sufficiently hot immediately to vaporize the molecules of oil as these are brought into contact with its surface.

In early designs the "boilers or gasifiers and their sleeves were fitted above the cyliudem In the later forms they were embodied in the 'cylinder heads in the manner described, but the ducts leading to the by-pass valve and carburetters were external. In the latest form, however, which we illusElate on an actual engine, even these ducts are east in one with the cylinder head, and so there is no tendency for recon-. densation of the fuel, as it is always kept at a satisfactory heat.

It will be noted that we have described the system aa applied to one cylinder only of the engine. It will be quite realized that the system is identical whether it be applied to one cylinder or a number, the ducts being arranged accordingly.

It will be seen that the sparking plugs are screwed into the tops of the boilers, and that the sleeves are held in position by nuts screwed on to the boiler heads. Each carbnretter has a separate throttle valve, but these valves are interconnected, and are operated by a single forked rod, so that the driver is not called upon to adjust his controls in any manner beyond altering the position of the oil-petrol lever on the. dash.

It has been shown in the tests carried out by the Company that the relative consumption of heavy oil is slightly greater than that of petrol, whilst the loss of power, due to expansion of the mixture through pre-heating and carrying it through longer distances, amounts to approximately 3 per cent., which is inconsiderable.

One of the useful points about the apparatus is that if on any occasion gas oil be not obtainable, it is quite possible to run for long distances using petrol only as fuel, providing that reasonable care be taken not to open the throttle too far and thus overheat the boilers.

Experience with vehicles running in Italy has shown that the apparatus is not affected by barometric changes. Vehicles fitted with the Vapour Oil device are in constant use over passes 8,000 ft. above sea-level, and, as an example of the hard work which others are performing, it is interesting to note that the Duke of the Abruzzi employs a fleet of 31 vehicles, all of Fiat make, for the carrying of ore in Somaliland, all these running on gas oil. The Vapour Oil device is also employed on all the large motor barges used at Venice.

Last week we were afforded an opportunity for carrying out a short road test on S 3i-ton Fiat fitted with the Vapour Oil apparatus. The vehicle carried a Raid of two tons and four :ersons. The morning was unusually cold. The engine was started on petrol at 10.48 a.m. from dead cold, and, after -tiling for a couple of minutes, was driven from the garage

One of the oil vapo izers with its Wee nut and spark, plug.

in Vauxhall Bridge Road towards Hyde Park Corner. At 10.55 a.m. the engine commenced running well on one-third oil and two-thirds petrol, and at 10.58 it was running at 15 m.p.h. on full-oil.

The oil used was not that recommended, it being an extraheavy Diesel oil with a sp. gr. of .91, and having a high con

tent of parafin-wax. Consequently, at • low speeds there was a certain amount

Urof pinking, but, apart from this, there tie, was no hesitation in the running, and n g 20 m.p.h. was quite • easily attained,

although the vehicle was an old exservice type.

During traffic driving the engine proved quite flexible, and never missed, but the exhaust emitted a small amount of clear blue vapour, which was almost absent when the vehicle was running normally.

We tested the apparatus on several

occasions by changing suddenly from oil to petrol and vice versa, but very little difference could be detected. We also tried a mixture of oil and petrol, and, whilst arresting pinking at low speeds, this had little effect at high speeds.

The vehicle was then driven up Nether hall Gardens, Hampstead, from a standing start at the bottom. It climbed this well on first gear, a change being made to second gear shortly after the bend. A second climb was then made running on petrol, and the difference in the power wq,s just sufficient to enable the whole climb to be made in Second gear, but this was an exceptionally severe test.

With the oils recommended—i.e., .880 sp. gr. and .890 sp. gr., with a small paraffin-wax content—no pinking whatever takes• . place, and there is no doubt that the results would have been even better, from the point of view of pulling.

One great advantage of the device is that

the oil is turned to vapour away from lie combustion .chamber proper, and it has been found that very little carbon is deposited in the _cylinders or on the pistons, although a certain amount of soot is found on the extcriks-of the boilers. By remoVing one nut of each boiler, however, this soot can easily be wiped away with a cloth.

'It may, be interesting to state that th6 company was formed some six months ago after the promoters had satisfied themselves, by extensive tests covering a period between July, 1923; and July, 1924, and a mileage of 20,000, that the Vapour Oil device could really, he employed with success on heavy corartiercial vehicles.

To convert an ordinary existing engine to burn heavy oils on the Vapour Oil system would cost soniething like £40, but, as we have pointed out elsewhere in this article, the cost would be much less than the alterations necessitated are carried out during the ordinary Course of manufacture.