SAVING FIFTY PER CENT. OF WHEEL WEIGHT

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

The Aluminium Cast Wheel for Commercial Vehicles is Behaving Well Under the Test to Which it is Being Subjected.

AS WAS RECENTLY remarked by Major Victor W. Page, who is a prominent writer on the subject of commercial-motor vehicles in the States, the• riding qualities of a commercial motor are as much to be considered as those of passenger cars, and they can be

improved by a reduction of the unsprung weight.

When a motor vehicle is travel ling at a fair speed over an irregular road,

there is a ten

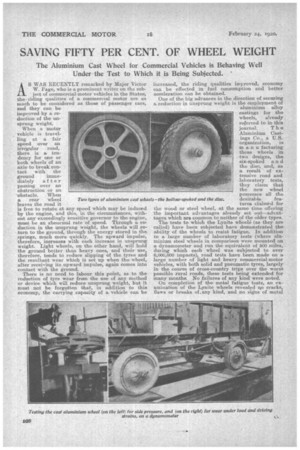

dency for one or both wheels of an axle to break con tact with the ground imme diately after passing over an obstruction or an obstacle. When a rear wheel Two types of aluminium cast whee leaves the road it is free to rotate at any speed which may be induced by the engine, and this, in the circumstances, without any exceedingly sensitive governor to the engine, must be an abnormal rate of speed. Through a, reduction in the unsprung weight, the wheels will return to the ground, through the energy stored in the springs, much more quickly. The upward impulse, therefore, increases with each increase in unsprung weight. Light wheels, on the other hand, will hold the ground better than heavy ones, and their use, therefore, tends to reduce slipping of the tyres and the resultant wear which is set up when the wheel, after receiving its upward impulse, again comes into contact with the ground. There is no need to labour this point, as to the reduction of tyre wear from the use of any method or device which will reduce unsprung weight, but it must not be forgotten that, in addition to this economy, the carrying capacity of a vehicle can be increased, the riding qualities improved, economy can be effected in fuel consumption and better acceleration can be obtained.

One of the big advances in the direction of securing a reduction in unsprung weight is the employment of aluminium alloy castings for the wheels, already referred to in this journal. The Aluminium Castings Co., a U.S. organization, is mann facturing these wheels in two designs, the six-spoked an d the disc, and, as a result of extensive road and laboratory tests, they claim that the new wheel possesses all the

Is hollow-spoked and the disc, desirable fea

tures claimed for the wood or steel wheel, at the same time offering the important advantages already set out—advantages which are common to neither of the older types. The tests to which the Lynite wheel i (as they are called) have been subjected have demonstrated the ability of the wheels to resist fatigue. In addition to a large number of laboratory tests (where aluminium steel wheels in comparison were mounted on a dynamometer and run the equivalent of 500 miles, during which each wheel was subjected to over 6,000,000 impacts), road tests have been made on a large number of light and heavy commercial-motor vehicles, with bath solid and pneumatic tyres, largely in the course of cross-country trips over the worst possible rural roads, these tests being extended for many months. No failures of any kind were noted. On completion of the metal fatigue tests, an examina,tion of the Ignite wheels revealed no cracks, flaws or breaks of,any kind, and no signs of metal fatigue were perceptible at any point in the wheels. On an examination of the solid tyres on these wheels, no cracks were to be found and the tyre cora was intact all the way round. Sets of tyres on steel wheels, which were being run at the same time and under the same conditions, for the purpose of comparison, showed that the tyres in these circumstances were worn so that a smooth edge existed at each edge of the face, whilst a number of deep lateral cracks were perceptible across the entire width of the face.

An important point is the question of heat. The temperature of a set of Lynite wheels, .after three hours' continuous running, was found to be 119 degross, and that. of steel wheels, running in the same circumstances, 127 degrees. A further series of tests is now being undertaken in order to ascertain the resistance Of the Lynite wheels to side thrust and radial compression.

In the matter of the careful study of wheel tyring, and in the matter of lightening of tyred wheels, the manufacturers in the United States are showing really commendable enterprise, and it is to be hoped that manufacturers on this side of the -Atlantic will not leave the whole of the running to their transatlantic competitors.