IN The eight-legger market increased by a massive 98.4% last

Page 106

Page 107

Page 108

Page 109

Page 110

Page 111

If you've noticed an error in this article please click here to report it so we can fix it.

year, recovering from a very low base of only 800 units in 1992. While the trend has continued upwards, now a slowdown in the construction industry could preempt a turndown in the eight-legger market. Without the promise of work, operators are reluctant to invest in new equipment with the result that the vehicle parc is becoming older and young secondhand vehicles are becoming ever more difficult to find.

This Used Truck Report spotlights the Leyland Daf eight-wheeler range which, back in 1991, was market leader with a 34.6% share. This was before its financial troubles which pre-empted a break-up of the company during the worst commercial vehicle recession the UK has experienced.

Miraculously, although much slimmer, individual fractions have survived through a number of separate management buyouts.

Daf Trucks NV continues to build heavy

Leyland Daf multi-wheelers are no-frills, hard working vehicles with a useful payload potential, but users and dealers do report some weak spots.

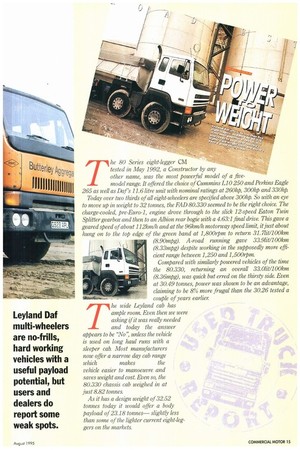

The 80 Series eight-legger CM tested in May 1992, a Constructor by any other name, was the most powerful model of a fivemodel range. It offered the choice of Cummins L10 250 and Perkins Eagle 265 as well as Daf's 11.6 litre unit with nominal ratings at 260hp, 300hp and 330hp.

Today over two thirds of all eight-wheelers are specified above 300hp. So with an eye to move up in weight to 32 tonnes, the FAD 80.330 seemed to be the right choice. The charge-cooled, pre-Euro-1, engine drove through to the slick 12-speed Eaton Twin Splitter gearbox and then to an Albion rear bogie with a 4.63:1 final drive This gave a geared speed of about 112km/h and at the 96km/h motorway speed limit, it just about hung on to the top edge of the green band at 1,800rpm to return 31.71it/100km (8.90mpg). A-road running gave 33.9lit/100km (8.33mpg) despite working in the supposedly more efficient range between 1,250 and 1,500rpm.

Compared with similarly powered vehicles of the time the 80.330, returning an overall 33.0lit/100km (8.36mpg), was quick but erred on the thirsty side. Even at 30.49 tonnes, power was shown to be an advantage, claiming to be 8% more frugal than the 30.26 tested a couple of years earlier

The wide Leyland cab has ample room. Even then we were asking if it was really needed and today the answer appears to be "No", unless the vehicle is used on long haul runs with a sleeper cab. Most manufacturers now offer a narrow day cab range

which makes the vehicle easier to manoeuvre and saves weight and cost. Even so, the 80.330 chassis cab weighed in at just 8.82 tonnes.

As it has a design weight of 32.52 tonnes today it would offer a body payload of 23.18 tonnes— slightly less than some of the lighter current eight-leggers on the markets.

trucks at Eindhoven in the Netherlands. In Lancashire Leyland Trucks produces a range of light and middleweight commercial and military trucks for the UK and the Continent. Leyland Daf Vans at Birmingham has retained its share of the UK van market while in Glasgow, Albion Automotive continues to make axles for van and truck models.

Spares back-up is provided by Multipart Distribution based at Chorley, while Leyland Daf Trucks, the marketing operation at Thame, handles the complete range from 3.5 tonnes to 38 tonnes-plus, supplied from Leyland Trucks and Daf Trucks.

• EVOLUTION

The Leyland Constructor 30.21 tipper chassis with the T45 cab was first on the scene, in January 1980, equipped with the Leyland TL11A 11.1-litre engine rated at 156kW (209hp), Eaton D473 gearbox and a 5.64m wheelbase. It continued to May 1984. when the TL11C, rated at 183kW (246hp), was introduced and ran in the 30.25 until May 1989.

As an alternative the six-cylinder Rolls Royce 220 engine was also offered in the 30.21 on special order from May of that first year through to December 1982.

A less powerful 6LXC Gardner engine also came on line in the 30.19 in May 1980. Two years later the 10.45-litre 6LXC rated at 172kW (231hp) replaced the earlier Gardner option, only to be dropped off the option list in November 1986.

In January 1982, the first 30.25 took the Rolls 265, rated at 183kW (254hp). Just over a year later there was another 30.25 with the turbocharged Cummins 10-litre LT10 delivering 177kW (238hp). The Rolls was dropped in November 1986 to be replaced by its new owners with the 12.17-litre Perkins Eagle 800, rated at 198kW (265hp)—its power was boosted to 224kW (300hp) in 1987. Daf's own 11.6-litre turbocharged KT191 was added to the list in April 1989.

The 3025 was discontinued with the Cummins L10 in September 1990, only to be replaced by a 186kW (250hp) version in the newly designated FAD80.250 the following month. This model took the Spicer 10speed constant-mesh box and Rockwell singlereduction axles and a sleeper cab became an option. The FAD80.260 with the Daf engine took the ZF nine-speed synchromesh box and hub-reduction axle.

The Eaton Twin Splitter box was introduced a month later on the Perkins-powered FAD80.270 and Daf-powered FAD80.330. The 224kW model was introduced in the summer of 1991.

With the launch of the 75 and 85 Series in 1993, the 70 and 80 Series Constructor 6x4s and 8x4s have since been discontinued.

• OPERATORS

James Pugh-Lewis now runs the transport operations for the company his father set up back in 1966 at Pilsley near Chesterfield. His brother Tim controls the fencing and drainage contracting side of the businesses. Over the past three years it has been necessary to cut the fleet back from 40 to 25 vehicles. Today he has a mixed fleet of Iveco, Foden, MAN and Leyland tractive units and eight-wheelers. Out of 12 8x4 rigids, eight are Leyland Daf 30.26 chassis.

"We do some muck shifting but our main work is from the opencast coal mines," he says. "With the closure of the deep mines the job has become more competitive; there is just less work to go round. The trucks do five loads a day and cover about 350km of which about 12km is off-road. It's a deep hole so they need low gearing to climb out of the cut but then they have to be able to run at 60mph on the motorway.

"My father bought our first Leylands," he adds. "The ones we have now were the result of a special trade-in deal we did on some Dregistered vehicles that were giving us some problems. We stayed with the Leyland Daf 30.26 because it has a very good payload of about 20.5 tonnes and that is grassing at 30.49 tonnes. Up to now I have mainly specified Wilcox or Don-Bur bodywork with Drum or Edbro tipping gear. They all have the small Cruiser cab; two are fitted with the Leyland TL 11C engine and the rest have Daf's KT191 11.6-litre engine rated at 256hp. It has the same rear end as the six-wheel Constructor with the three-spring parabolic suspension used to locate the Albion hub reduction axles.

'They would be too expensive to uprate so we will continue to run them at the old weight," says Pugh-Lewis. "That will still give us more payload than we would get from some of the new 32-tonners. They are running up to 80,000km or so a year. I would like to be clear of them in an other 12 to 18 months—six to seven years is as much as I need them. Fuel consumption can vary day to day but overall they are returning between 48 and 461W100kin (5.9-6.1mpg). I sold some 12 months ago and didn't get a very good price at all but just recently I have just been looking for some young secondhand vehicles and they are fetching a better price now.

"As far as new vehicles go," he says, "I am waiting to see the lightweight Iveco eightwheeler with the Seddon Atkinson chassis and Iveco engine. The Leyland Daf 85 Series looks very good too, but of course it's not a Leyland any more. Whatever we choose it's not worth considering anything below 320hp and it will need a 12 or 13-speed transmission to maintain the speed. We had some early problems with the diffs on the 30.26s but that was mostly solved by Leyland. Diffs, half

shafts and hub reduction fail regularly they are just not up to the work we use them for.

"The suspension bushes wear very quickly," he reports, "and it's not unusual to have to replace them twice a year. Because they locate the axle they have to withstand the tractive force. The rear bogie design was probably OK for the six-wheeler but the eight-wheeler's greater torque is too much for it. Propshafts break off at the flanges so we have heavy duty ones made up. Trunnion bolts also have a habit of snapping off.

"The Daf engine is one of the plus points," he adds. "We have never had to strip one down and I can't fault the nine-speed ZF box either. We had some manifolds crack but that's probably caused by the wheel wash at the mine. The TL11 is another story: most of its problems are due to insufficient cooling. There are no problems to talk of with the steering or brakes and the chassis stands up to the work OK. The cab is low on creature comforts and suffers from rust as it gets older but the ground clearance is good and it's a nice vehicle to drive. The high-ratio steering is good for manoeuvring.

"We have moved up from 10 to 15 weeks on oil changes without any problems," says Pugh-Lewis," but we take the occasional sample to keep a check. Our local dealer has just gone over to Iveco but the Leyland Daf network is very good and I have no complaints on warranty. It might sound as though we have had a lot of problems but we have put up with them because of the payload."

Drinkwater Sabey is part of the Attwood group of companies, which has interests in waste management, recycling, municipal services, landfill and quarry products in the UK. It runs a fleet of 362 vehicles. Most of them are multi-axle Volvos but the fleet includes a number of Mercedes 4x2 skip loaders and a growing number of artics, providing collection services to some 20,000 businesses and 320,000 households in the UK.

"We have about 25 Leyland Daf eightwheelers," says fleet administration manager Paul Washington. "Just under half of them were acquired through company acquisitions They are mostly fitted with Jack Allen bodies but the suspension is wrong for operating on soft landfill sites. When the wheels go in to the axles the suspension bottoms out. It acts as a skid so that the vehicle looses traction, then it has to be either towed or pushed out. Apart from becoming unpopular this inevitably leads to vehicle damage.

"We bought a couple of new 30.33 Constructors on ET and G plates," he says. "One of them went through eight clutches in under two years and was finally upgraded by the dealer. Both of them had new axles under warranty— they couldn't stand up to the work they were doing and just fell apart. We have 13 30.30 chassis fitted with tanks which work in a haulage environment and they are as good as any other vehicle doing the job, but they are not suited to the refuse collection work.

"The RCVs cover about a 1,000 miles a week with a lot of stop/start and repeated PTO operation," Washington explains. "We expect to get between eight and lOmpg. Residual values of RCVs tend to be quite low in general: I would like to replace them after five years when we refurbish the chassis but as we refurbish the bodies at four years they are often worth more to us than we can get for them, so we run them for as long as is practical. Traditionally, we purchase all new vehicles and obtain the full warranty and servicing package on offer but we are looking at contract hire.

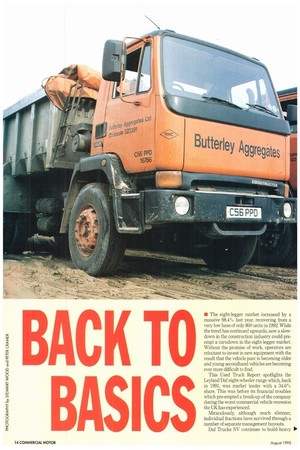

"We carry out servicing at eight of our 45 operational depots in the south," he adds. "With so few Leylands we don't carry the same amount of spares for them as we do for our Volvos. The availability of spares from some Leyland dealers, outside of normal working hours, leaves a lot to be desired", Butterley Aggregates, a subsidiary of RMC, has its head office in Lincoln and operates a fleet of 38 vehicles including four Constructor six-wheelers, one Ford Cargo 2421 and 33 eight-wheeled Constructors ranging from A to H registrations.

They carry limestone, sand and gravel from the company's quarries and pits, which are located in the east, between Peterborough

vailability of -from some Leyland dealers, outside of normal working hours, leaves a lot to he desired'

Scunthorpe, to customers throughout the country Transport supervisor Peter

Hunt says: "They are not a bad truck but as they get old they take a lot of looking after. But because they are virtually all the same we have the repairs off to a tee. There isn't a job on them that we couldn't do. The earliest eight-wheelers are fitted with the Gardner 230 turbo and the later ones have the Cummins LIO 250 engines. It was a group decision made by our engineering and transport division to buy Leyland Dais but we haven't had any new ones in the last two years.

"We reckon to cover 50,000 miles a year," says Hunt, "and aim to run loaded each way, but we can't always manage it. They are all plated at 30.49 tonnes and will carry up to 20.5 tonnes of payload. The best fuel consumption is from the Cummins L10 250 at 8.2mpg but the average across the fleet is about 726mpg. We refurbish them and make them as good as new but there is always something that will go wrong with them. When they get old they take a lot of maintenance.

"Nothing major has gone wrong with the later H-reg vehicles and the engines don't give us much trouble considering the amount of work they do," he adds. "Springs and rear suspensions have been uprated and modified. When they are well into their life they start to give problems with cab electrics, starter motors, wheel bearings front and back, diffs, and propshafts. Warranty from new normally includes two years on the engine and driveline. We have taken some back after five years and had chassis modifications done and there is no problem whatsoever with local back-up. I think the company will stay with Leyland Dd. When we move up to 32 tonnes it will probably be with the 85.300 Series with the Daf engine. "We do oil/filter changes at 20,000km," says Hunt, "but Mobil takes oil samples from the engines, gearboxes and diffs regularly every 40,000km and carries out diagnostic checks on the engine. It can show up the problems before we notice them and 99% of the time they are spot on with the diagnosis."

• DEALERS

Paul May of Chaddesley Commercials i n Kidder minster reports: "Late Leyland Daf eight-wheelers are very hard to come by. They do appear, and always will do, but they are getting scarcer and scarcer. Any good late vehicle of any make is getting hard to find but tippers are the hardest of all.

"Most of the Leyland Constructors come with either the 10-litre Cummins or the Leyland TL11 engines," he says," but we have had later ones with the 300hp Perkins engine. I — don't know of anyone who has had the 85 Series yet with the Daf engine.

"It's easier to sell Volvos and Scanias but we still sell a lot of Leyland Dais," says May." It's a good truck. The cabs are a bit dated but being basic they are easy to clean. You can stick a hose or steam cleaner in and clear it out—if you did that to a Scania or Volvo you would wreck everything. It's a working man's cab. We don't see many with sleeper cabs. Over 90% of tippers must be with day cabs, The sleeper cabs are usually on trucks with the larger bulk bodies. Most of the operators buying secondhand are sticking to 31 tonnes to keep under the tax limit and the Cummins will pull all day at that weight."

Despite being a Leyland Daf franchised dealer, Watts Truck Centre of Gloucester is not restricted to selling Leyland Daf used trucks. Mike Curtis shares May's view that there is a shortage of good late multi-wheelers: "Would you believe I have reverted to selling vehicles as far back as '83 if they are good and tidy," he says. "We are in a very strong tipping area and we sell a lot of vehicles into south and mid-Wales, The Leyland Daf Constructor is still one of the most popular and there is an abundance of customers seeking them.

"It must be because its spring time," says Curtis. "There is a lot of road work and construction going on and the tipper work always picks up at this time of year. I think the majority of companies tend to buy secondhand vehicles for the short term and fill the immediate need. Owner-drivers buy as late as they can afford and go up market.

"I still think the proprietary brand of engine, Cununins and Perkins, would outsell the Daf 11.6-litre,"he adds, "It's a question of the perceived engine and what the customers are used to.

"People do like to go for the rubber suspension. It gives less problems in the long run although it gives a different type of ride. Rubber became an option in the late '80s and some people had their chassis converted by specialists but it was not offered as standard. The Rockwell axles with the Scanunell back end was also an option but became the standard in about 1989. Although the Leyland hub reduction gave good ground clearance it had problems. It was very noisy and had a tendency to break up."

• SUMMARY

Late 8x4 Leyland Dafs are not any easier to find than any other used trucks. The rear suspension, drive axles, propshafts and cabs are all areas that can give problems. Proprietary engines are probably more popular than either the Leyland or later Daf versions. They are popular with large and small companies alike but owner-drivers will probably go for something a bit more up market. The payload is a strong point but it is too expensive to uprate early models to the new maximum weight

by Bill Brock