• Foden's reputation for building robust trucks with high payloads

Page 100

Page 101

Page 102

Page 103

Page 104

Page 105

If you've noticed an error in this article please click here to report it so we can fix it.

has always placed it amongst the top three or four truck builders when it comes to eight-wheelers. Add to this the option of proprietary engines from Cummins, Perkins and Caterpillar with a wide range of power options and a choice of nine or 13-speed Fuller boxes or the Eaton Twin Splitter transmission and Eaton or Rockwell axles with cross and inter-axle diff-locks, and you have the ingredients for what many operators consider to be the best on/off road driveline in the business.

Foden was the only UK truck manufacturer to offer Caterpillar engines. European emission regs have ruled them out of court for the time being but Euro 2 versions are expected soon. Caterpillar engines are common in plant equipment so they were readily accepted by a large number of operators in the construction industry.

If you don't like the Cat you can always Iv'

Foden's Catpowered eightlegger has a tough driveline and a good residual value. But nothing's perfect: a bit more attention to detail and dealer backup wouldn't go amiss.

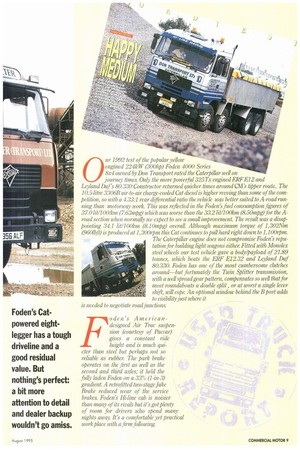

Our 1992 test of the popular yellow engined 224kW (3oohp) Foden 4000 Series 8x4 owned by Don Transport rated the Caterpillar well on journey times. Only the more powerful 325 Tx engined ERE E12 and Leyland Daf's 80.330 Constructor returned quicker times around CM'S *per route. The 10.5-litre 3306B air-to-air charge-cooled Cat diesel is higher revving than some of the competition, so with a 4.33:1 rear differential ratio the vehicle was better suited to A-road running than motorway work. This was reflected in the Foden's fuel consumption figures of 370 lit/100/km (763mpg) which was worse than the 33.2 lit/100km (8.50mpg) for the Aroad section when normally we expect to see a small improvement. The result was a disappointing 34.1 lit/100km (8.10mpg) overall Although maximum torque of 1,302Nm (9601bft) is produc.ed at 1,300rpm this Cat continues to pull hard right down to 1,100rpm. The Caterpillar engine does not compromise Foden's reputation for building light wagons either. Fitted with Monolex steel wheels our test vehicle gave a body/payload of 21.89 tonnes, which beats the ERF E12.32 and Leyland Daf 80.330. Foden has one of the most cumbersome clutches around—but fortunately the Twin Splitter transmission, with a well spread gear pattern, compensates so well that for most roundabouts a double split, or at worst a single lever shift, will cope. An optional window behind the B post adds to visibility just where it

is needed to negotiate road junctions.

Foden's Americandesigned Air Trac suspension (courtesy of Paccar) gives a constant ride height and is much quieter than steel but perhaps not so reliable as rubber. The park brake operates on the first as well as the second and third axles; it held the fully laden Foden on a 33% (1-in-3) gradient. A retrofitted two-stage Jake Brake reduced wear of the service brakes. Foden's Hi-line cab is noisier than many of its rivals but it's got plenty of room for drivers who spend many nights away. It's a comfortable yet practical work place with a finn following

specify 10 and 1 4 -litre Cummins engines, while Perkins Tx 12-litre units, developing high levels of torque low down the rev range, have consistently returned good fuel consumption figures in CMroadtests.

• EVOLUTION

Foden's light but strong high-tensile steel chassis with aluminium crossmembers was carried forward with the introduction of the revised 4000 Series eight-wheelers in May 1987 with a choice of steel, rubber and air suspension. The eight-legger uses much the same GRP cab structure as pre-4000 Series models—but with a smoother external profile. The internal design had been revised to incorporate a dog-leg binnacle with a smarter instrumentation package; seat belt anchor points were fitted standard for the first time.

Popularity of the exceptionally light 12.7litre 6LXDT Gardner engines, initially at 201kW (270hp) and later at 216kW (290hp), was on the wane and so were dropped. The smaller LT10-250 Cummins engine, rated at 187kW (250hp), was retained alongside the new 10.45-litre 3306B Caterpillar engine rated at 201/224kW (270/300hp). In June 1987 the 10-litre Cummins engine was also offered at 216kW (290hp); it was joined in August by the Perkins Eagle unit, also rated initially at 216kW (290hp).

From January 1991 the engine options were expanded to include the Cummins Super E 465, 410 and 365, and Perkins' Eagle 300Tx, 325Tx and 375Tx.

The S108 8x4 tipper chassis arrived at the start of 1992; engine options included the Cummins LTA10-275/325, Super E 320/365. The 224kW (300hp) 3306B Caterpillar engine was joined by the 3406B rated at 350/425hp; Perkins added the 350Tx variant.

In May 1992 Foden put its narrow cab from the 17-tonne chassis on to the 3000 Series eight-wheeler chassis rated at up to 242kW (325hp). In June the full-width cab received a revised grille and Hi-line roof to bring it in line with the tractive units; a 6.05m wheelbase was introduced to prepare for the move to 32 tonnes at the start of 1993.

The 'new' 4000 Series came along in May 1995 with updated cab and engine line-up which included Cummins' all-electronic 11litre M11 alongside the L10.350E.

• OPERATORS

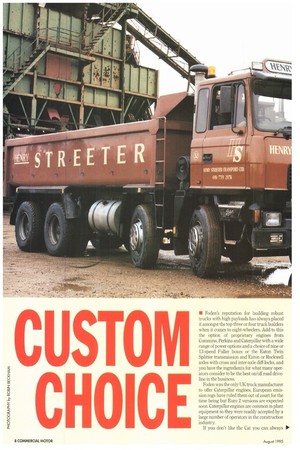

Terry Howell, transport manager for Henry Streeter Transport of Harlington, Middlesex runs 17 Foden eight-leggers, They include old 2000 Series models fitted with 290 engines and the current 4000 Series powered by Caterpillar's 300 and Perkins' Eagle 330Tx. The company has operated Fodens for 34 years and used to hold a Foden franchise. The vehicles mainly operate within 25 miles of base, delivering five or six loads of sand and gravel a day. They cover 50-60,000km a year and, with back loads of muck, run full for about 75% of the time. The entire fleet is fitted with day cabs and rubber suspension_ "We originally moved to the Cat engine after becoming dissatisfied with the service from Gardner and we would still be buying them if they met the Euro 1 specification", says Howell. "They carry a 30-month warranty, compared with 12 months for Gardner and 24 for Perkins. The extra tonne is important to us and we operate our three new vehicles, with the Perkins engines at 32 tonnes, but the existing fleet will still run at 30 tonnes. We get a payload of 20 tonnes with them but, because we have specified thicker floors for the new trucks, we on13r get 21 tonnes at the higher GVW. The Cats give us about 4114 lit/100km (7.0mpg) and with the Gardners we get about 51.414/100km (5.5mpg) which is not so bad as we do a lot of town work.

"At one time we had a four to five-year replacement policy," he adds. "Recently we took delivery of the three trucks fitted with the Tx engines and they are the first we have bought for three years. The Gardner engines are in our older vehicles and they cost a lot more on maintenance: we have had trouble with head gaskets and heads cracking over the past year. They're sold off to private individuals and they are easy to sell, but eight and nine-year-old trucks are not going to fetch good money.

"We've got our own workshop that does all of the servicing," says Howell. "They stick to the manufacturer's recommended schedules. The local dealer delivers daily and if they don't have a part in stock they usually have it to us by eight o'clock the next morning. It's mostly service items we need—the rubber suspensions last pretty well and the whole specification improves with the years."

Earth-moving contractor CJ Pryor has been in business in Harlow, Essex for 30 years. Managing director John Pryor says: "We have had Fodens for most of that time. We bought them originally because they were a British truck with a reputation for reliability. There are 25 road-going units which include 22 8x4 tippers. Fourteen of them are Fodens; the other seven are Leyland Dafs but muck moving forms a relatively smaller side to the core of our business which employs some 200 units of plant. The Cat engines fit in well because of our use of earth moving equipment.

"Fodens cost a bit above the average in the market place," he says. "We usually specify Wilcox aluminium bodies and either Edbro or Hyva tipping gear. The payload is 20 tonnes at 30.5 tonnes but they are only loaded one way. Our mileage isn't very great but we get about 40.41it/100km (7.0mpg). We might move up to 31 tonnes with the current fleet and go to 32 tonnes as we replace them.

"We keep them indefinitely," says Pryor. "Eventually they either get cut up for spares or we might convert them to site vehicles. There is no set policy. We try to replace a couple every year but we haven't managed that over the past 18 months. They are a premium truck and fetch a premium price so we do look at other alternatives. We follow a strict preventative maintenance system and in a mixed fleet, where ages do vary, the Fodens are costing 15 to 20% less than the Leyland vehicles. The residual values are better too, which influences the purchasing decision. They represent more in the bank if it's ever needed for a rainy day".

Don Transport of Telford is a family business run by a father and four sons. Phil Hughes, one of the brothers, put his truck up for Of to test in 1993. The eight-vehicle fleet includes a couple of road sweepers, a Cummins-engined artic and five sleeper. cabbed Foden eight-leggers with Caterpillar engines, nine and 13-speed Fuller boxes and three Twin Splitter boxes. Three are on rubber; the other two have Foden's Air Trac.

"I wish we had never bought them on air," says Hughes. "The spring at the back kept breaking. Both vehicles have had a complete set now. They started breaking just after they were twelve months' old and it's always the bottom leaf in each one that cracks up. They are .:190 each time and each truck has four. The latest problem is that the mountings on the axles are breaking up. That truck went back to Sandbach for a couple of days to be repaired—it's only been back on the road two weeks and it's gone again, For what good they did they might never have bothered. We never have any trouble with the rubber suspensions. The F-reg vehicles are still on the original rubber blocks but they might need changing on one of them this year.

"They are due to be put up to 30.8 tonnes as nothing needs to be done for that," he adds. "The two J-reg and the L-reg will go up to their design weight of 32 tonnes. We get 21.5 tonnes payload out of the J-registered ones but the L-reg is slightly longer and heavier so it only gives us 20.5. The two oldest have Stag aluminium bodies, the two Js have got Wilcox bodies

with an extension to make them into bulkers and the latest one has got a Weightlifter body on it They have a mixture of Hytec, Drum and Carrymore tipping gear. They usually return between 40.411t/100km and 37.7 lit/100km (7.0 and 7.5 mpg) running up to 80% loaded," says Hughes. "We're look. ing for seven years out of them but the two on air might not stay that long, The F.-registered chassis are good for another five years yet. The sleeper cabs make them sell better than if they had day cabs. We used to run plant so we knew about the Cat engine and took one of the first in Shropshire. They haven't given us any trouble at all.

"Resale values have always been pretty good in the past," he adds. "We shopped around before we bought the last two and should have bought a couple of ERFs, the last before the EC, but ERF let us down at the last moment. There is room for improvement in the cabs. We have the Hi-line on the later ones, for a bit more comfort. We had problems with the air suspension deflating so we went back to the mechanical suspension for the seats. The heaters are not as good as they ought to be; to get the screen to clear it has to be on full blast The trim could be a bit darker for our work and the dashboard is not easy to wipe clean—it seems to hold the dirt. The rubber mats are fixed but dirt gets underneath through a gap by the accelerator pedal. The only way to clean it is to remove the chrome strip by the door and vacuum it out "We had a problem with the foot valve on the Is," he reports. "They didn't deliver full pressure to the brakes. It took 11 months to sort that out. With use the cable linkage for the gearbox becomes less positive to the left and right of the gate. Tyres don't seem to last as long as they used to either.

"We do most of our own maintenance but at times we have sent them back to Sandbach Truck Services under warran ty: vehicles have been off the road for a whole day waiting for a few odd parts to arrive from

the factory which is just across the road. The back-up service from the factory is not as good as it ought to be. There always seem to be a number of excuses as to why they can't do anything for us even though we have booked the vehicle in beforehand. We are thinking of putting another one on next year," he concludes, "and might try a different make—maybe the new Iveco".

• DEALERS

Pelican Engineering of Leeds dates back to just after the Great War; it became one of the first Foden franchises in 194,3. Sales manager Ken Grindrod believes the shortage of used vehicles is linked to the upturn in sales of new vehicles.

"We tend to find that if the used vehicle market is busy then the new vehicle side is quiet," he explains. "The surplus of used vehicles has dried up and if people can't find them they are being forced into buying new ones. I advertise for used eight-wheelers every week and I will quite happily buy E-reg vehicles or older for stock because they still attract a high resale value. A younger vehicle, say a Greg, will fetch £25-28,000 depending on specification and the condition. The Caterpillar has been our most popular selling engine right up to the 1st of October. Up to 95% of the vehicles we supply have been on rubber suspension. It's been standard equipment for the past eight years and its reliability has been excellent. The Air Trac is not so popular—it's a Kenworth design which Foden has developed for the British market. When we put it on eight-wheelers we found that the bags deflated very slowly but we changed that by fitting new dump valves.

"The secondhand market is split about 50/50 between companies and owner-drivers," says Grindrod, "so the day cab models sell just as easily as those with sleeper cabs. The advantage of a Foden is that you don't lose out on body length because of the sleeper cab— you can't fit the tipping gear any further forward than the over bell cross member, located above the gearbox. With a day cab steps take up the extra space. The GRP cab lasts, it's not going to rot away. There isn't another manufacturer that can custom-build a vehicle to the extent that Foden can. That's a major benefit to the customer because he can get exactly what he wants as the vehicle comes off the production line in his colours. There is nothing he has to add on later.

"There is nothing prone to failure that I can advise you to look out for," he adds. With any vehicle you must ask yourself is the engine all right, does it change gear as it should, does it drive OK".

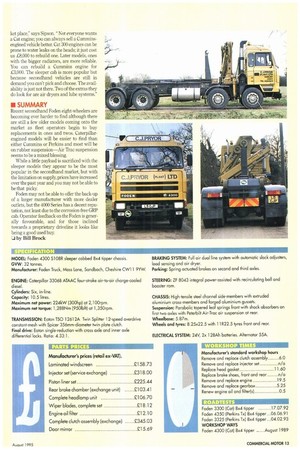

Four years ago Geoff Sipson set up on his own with a used truck business based in Coventry. At the height of the recession he must have got something right because he now has over £250,000 of stock.

"Eighteen months ago I was finding it hard to buy tippers of any age but I have never bought so many as I have over the past six months," he says. "Last year was near a record for new vehicle sales and we have benefited from the knock-on effect. With more younger vehicles becoming available we have seen prices drop by about 12,000 in the past three months for the average four to five-yearold eight-legger.

"The Foden stands up very well in the mar ket place." says Sipson. "Not everyone wants a Cat engine; you can always sell a Cumminsengined vehicle better. Cat 300 engines can be prone to water leaks on the heads; it just cost us £8,000 to rebuild one. Later models, ones with the bigger radiators, are more reliable. You can rebuild a Cummins engine for £3,000. The sleeper cab is more popular but because secondhand vehicles are still in demand you can't pick and choose. The availability is just not there. Two of the extras they do look for are air dryers and lube systems."

• SUMMARY

Recent secondhand Foden eight-wheelers are becoming ever harder to find although there are still a few older models coming onto the market as fleet operators begin to buy replacements in ones and twos. Caterpillarengined models will be easier to find than either Cummins or Perkins and most will be on rubber suspension—Air Trac suspension seems to be a mixed blessing.

While a little payload is sacrificed with the sleeper models they appear to be the most popular in the secondhand market, but with the limitation on supply, prices have increased over the past year and you may not be able to be that picky.

Foden may not be able to offer the back-up of a larger manufacturer with more dealer outlets, but the 4000 Series has a decent reputation, not least due to the corrosion-free GRP cab. Operator feedback on the Foden is generally favourable, and for those inclined towards a proprietary ciriveline it looks like being a good used buy.

by Bill Brock