IT'S THE TRANSPO.RT THAT COUNTS

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

The text-book operation of John Player's transport protects a daily investment of more than £1 million and the regular supply of cigarettes to a multiplicity of retail outlets. The continued and efficient operation of the Horizon factory at Lenton depends on it, too

by Johnny Johnson

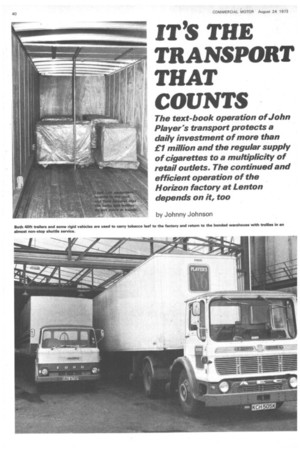

LARGE SUMS are often at stake in the operation of road transport particularly when it is used by a manufacturer as an extension to a production line delivering raw material to the processing plant and distributing the finished product to the consumer.

There can be few manufacturers, however, who depend on the flexibility and efficiency of road transport to protect an investment of more than £.1 million every day as does John Player and Sons at its Nottingham factory. Each day, a cheque for this amount is deposited with HM Customs and Excise to release tobacco from the company's bonded warehouse at Radford and any delay in transforming this into a saleable product could have considerable financial consequences.

It is from this point that Player's own transport fleet takes over carrying the tobacco to the new factory on the Lenton industrial estate about three miles away and transporting the finished cigarettes to distribution depots at Brimsdown in London, York and Glasgow.

Tobacco is drawn from the warehouse in different varieties and quantities according to the demand of the day's production schedule. Leaf tobacco is packed in bales which are loaded into vehicles using low four-wheel trollies and transferred quickly to the factory. For the bales of leaf, three 40ft York trailers are used. These LB26 Freightmasters can carry about 21 of the 8501b bales and they have guide-rails along the side walls so that the trollies do not damage them. The rails also serve to locate the bales in the trailer.

Load-Lok equipment is provided to retain the bales in position during transit. It is built into the floor and roof so that a single bar will prevent both trollies and bales from moving.

The average payload is between eight and nine tons and for this job the company has specified the trailer with tandem axles fitted with single wheels and tyres. The tractive units are Ford D1000 and AEC Mercury.

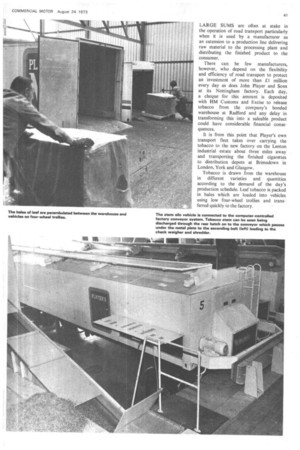

Although the leaf is easily handled into the factory on the wheeled trollies, the delivery of this type of tobacco is not as sophisticated as the handling of tobacco stem Stem is transported in a purpose-built trailer built by Charrold Ltd, Huntingdon, on a Crane Fruehauf single-axle skeletal trailer. It comprises a 30ft aluminium-clad body which encloses a stainless-steel hopper, 8ft wide by 511 6in. high to guard against contamination. A conveyor belt runs along the bottom of the vehicle and this is driven by a Pye TASC unit three-phase 7+hp electric motor and a 200:1 reduction gear providing a variable speed of + rpm for the conveyor so that stem is discharged through a small oblong rear hatch. The vehicle is loaded through an air-operated one-piece hatch which runs the length of the top of the body. There are two air reservoirs for hatch operation and it can be manipulated either from these or from an external source. This means that the hatch can be opened or closed when the vehicle is free standing and independent of the traction unit.

Stem is cleared from the warehouse and into the vehicle along a conveyor belt system which incorporates magnets to remove metal objects. When the vehicle arrives at the factory it is connected to an automatic discharge system controlled by a computer.

The rear hatch is positioned over the beginning of a conveyor belt system taking the stem to the production line. The computer is programmed according to the demands of the day's production schedule and the rate of discharge varies according to the particular needs of the moment.

The stem is conveyed into the factory where it is check-weighed and shredded and passed on to the next process automatically in a continuous flow line.

For this reason, the company runs five of these vehicles so that one is loading at the bonded warehouse, one is in transit and two are positioned at the factory delivery dock. There is one spare for maintenance, DoE testing, and for emergencies.

Artics and rigida Player's operates a total of 70 vehicles and 60 trailers on its 0 licence and this fleet comprises artics drawing 30ft and 2411 trailers as well as rigid units. The majority of the vehicles are employed in carrying the finished cigarettes to the three distribution depots and this operatien is vital to the company's profitability, too.

In a fiercely competitive market such as cigarette retailing, it is imperative that the supply to the consumer is maintained in accordance with demand. The alternative is that the consumer will buy another brand.

Therefore, although the company is exceedingly transport cost conscious, it has to balance the cost of the transport provided with the convenience of delivery and the service to the customer.

Nevertheless, a close cost control is maintained on the delivery fleet for Player's knows how much the cost of transport can influence the cost of the finished product and the profit margin which exists.

Not all of the vehicles which remain after the bond-factory shuttle vehicles have been discounted are engaged on the distribution activity, however.

Some of the rigids are used, as are the 40ft York trailers, to carry trollies back from the factory to the warehouse and, naturally, they also return with leaf tobacco bales. Some of them are used to carry back to bond tobacco unsuitable for manufacturers on which the Customs will allow an amount of tax drawback provided it conforms to certain specified standards of cleanliness and purity.

Three other vehicles are 2711 6in.long York SFT 28 step-frame semi-trailers which are used to supply the factory with materials other than tobacco. These are cardboard cartons, cigarette papers, stationery and so on.

The company's transport operation is a well-planned co-ordinated activity which amounts to a classic example of the way in which transport should be used to the utmost econoinical advantage.