Vehicle Remodelling to Save Renewal

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

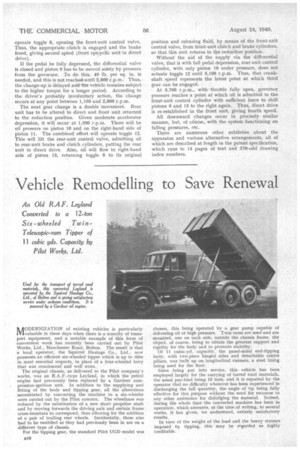

An Old R.A.F. Leyland "Converted to a 12-ton

Six-wheeled TwinTelescopic-ram Tipper of 11 cubic yds. Capacity by Pilot Works, Ltd.

AODERNIZATION of existing vehicles is particularly /VIvaluable in these days when there is a scarcity of transport equipment, and a notable example of this form of conversion work has recently been carried out by Pilot Works, Ltd., Manchester Road, Bolton. The result is that a local operator, the Squirrel Haulage Co., Ltd., now possesses an efficient six-wheeled tipper which is up to date in most essential respects, in place of a four-wheeled lorry

that was obsolescent and well worn. •

The original chassis, as delivered to the Pilot company's works, was an R.A.F.-type Leyland, in which the petrol engine had previously been replaced by a Gardner compression-ignition unit. In addition to the supplying and fitting of the body and tipping gear, all the alterations necessitated by converting the machine to a six-wheeler were carried out by the Pilot concern. The wheelbase was reduced by the substitution of a new short propeller shaft and by moving forwards the driving axle and certain frame cross-members to correspond, thus allowing for the addition of a pair of trailing rear wheels. Incidentally, these also had to be modified as they had previously been in use on a different type of chassis.

For the tipping gear, the standard Pilot UGD model was chosen, this being operated by a gear pump capable of delivering oil at high pressure. Twin rams are used and are mounted, one on each side, outside the chassis frame, the object, of course, being to obtain the greatest support and rigidity for the body and to promote stability.

Of 11 cubic-yd. capacity, the panel-sided end-tipping body, with two-piece hinged sides and detachable centre pillars, was built up on longitudinal runners, a steel lining being used for the floor, Since being put into service, this vehicle has been employed largely for the carrying of tarred road materials, the usual pay-load being 12 tons, and it is reported by the operator that no difficulty whatever has been experienced in discharging the full quantity, the angle of tip being fully effective for this purpose without the need for recourse to ,any other assistance for dislodging the material. Indeed, during the whole time the converted machine has been in operation, which amounts, at the time of writing, to several weeks, it has given, we understand, entirely satisfactory results.

In view of the weight of the load and the heavy stresses imposed by tipping, this may be regarded as highly creditable.