WORKSHOP AND GARAGE NOTES.

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

Some Useful Contributions from Our Driver and Mechanic Readers.

Tightening a Fan Belt.

1/rUCIE trouble that is experienced ..l.V.Lwith overheated engines, boiling and loss of water may be traced to an inefficient drive for the fan. The fan may appear to be revolving at its correct speed, but in this case, as in so many others, the eye may easily be deceived.

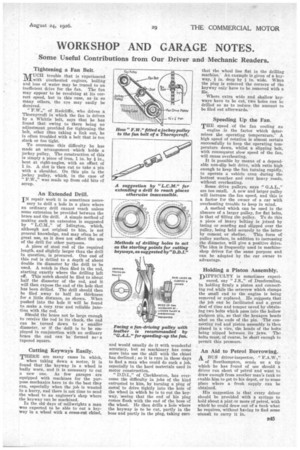

" F.W.," of Radcliffe, who drives a Thornycroft in which the fan is driven by a Whittle belt, says that he has found that owing to there being no adjustment provided for tightening the belt, other than taking a link out, he is often troubled with a belt that is too slack or too tight.

To overcome this difficulty he has made att arrangement which holds a jockey pulley. The construction of this is simply a piece of iron, 1 in. by / in., bent at right-angles, with an offset of 1 in. A slot is then cut to take a pin with a shoulder. On this pin is the jockey pulley, which, in the ease of was made up from odd bits of scrap.

An Extended Drill.

IN repair work it is sometimes neces sary to drill a hole in a place where an ordinary drill cannot reach unless some extension be provided between the brace and the drill. A simple method of making such an extension is suggested by " L.C.M.," of Islington, which, although not original to him, is not general knowledge, and may often be of great use, as it does not affect the use of the drill for other purposes.

A piece of steel rod of the required length, and slightly larger than the drill in question, is procured. One end of this rod is drilled to a depth of about double its diameter by the drill to be used.. A notch is then filed in the rod, starting exactly where the drilling left off. This notch should be filed to about half the diameter of the rod, and it will then expose the end of the hole that has been drilled. The drill should then be filed away to half its thickness for a little distance, as shown. When pushed into the hole it will be found to make a very true and reliable junelion with the rod.

Should the brace not be large enough to receive the rod in its chuck, the end can be turned down to a smaller diameter, or if the drill is to be employed in conjunction with an ordinary brace the end can be formed as a tapered square.

Cutting Keyways Easily.

THERE are many cases in which, when taking down a motor, it is found that the keyway in a wheel is badly worn, and it is necessary to cut a new one. As few garages are equipped with machines for the purpose mechanics have to do the best they can, especially when the job is wanted in a hurry, and there is not time to send the wheel to an engineer's shop where the keyway can be machined.

In the old days of millwrights a man was expected to be able to cut a keyway in a wheel with a cross-cut chisel, and would usually do it with wonderful accuracy, but as machinery has come more into use the skill with the chisel has declined; so it is rare in these days to find a man who could do such a job, especially in the hard materials used in motor construction.

" D.D.I.," of Cleckheaton, has overcome the difficulty in jobs of the kind entrusted to him, by turning a plug of metal to drive tightly into the hole of the wheel in which he is to cut the keyway, 'seeing that the end of his plug comes flush with the end of the boss of the wheel. He then drills a hole where the keyway is to be cut, partly in the boss and partly in the plug, taking care that the wheel lies fiat in the drilling machine: An example is given of a keyway, / in. deep by in. wide. When the plug is removed the corners of the keyway only have to be removed with a file.

Where extra wide and shallow keyways have to be cut, two holes can be drilled so as to reduce the amount to be filed out afterwards.

Speeding Up the Fan.

THE speed of the fan cooling an

engine is the factor which determines the operating temperature. A high speed of rotation is almost certain successfully to keep the operating temperature down, whilst a slipping belt, with consequent slow speed of the fan, will cause overheating.

It is possible by means of a dependable non-slip belt drive, with ratio high enough to keep the fan turning rapidly, to operate a vehicle even during the hottest weather and over heavy roads, without overheating.

Some drive pulleys, says " G.A.L.," are too small. A new and larger pulley will increase the fan speed, and this is a factor for the owner of a car with overheating trouble to keep in mind.

A method which can be used in the absence of a larger pulley, for flat belts, is that of filling the pulley. To do this a piece of heavy belting is joined by lacing or scarfing and slipped over the Pulley, being held securely to the latter by cement or shellac. This form of pulley surface, in addition to increasing the diameter, will give a positive drive. The idea is frequently used in machineshop drives for the same purpose and can be adopted by the car owner to advantage.

Holding a Piston Assembly.

DIFFICULTY is sometimes experi enced, say " J.S.," of Dunfermline, in holding firmly a piston and connecting rod while the setscrew which clamps the small end to the engine is being removed or replaced. He suggests that Elie job can be facilitated and a great deal of time and temper saved by obtaining two bolts which pass into the hollow gudgeon pin, so that the hexagon heads abut on the ends of the pin. The connecting rod and piston assembly is then placed in a vice, the heads of the bolts being nipped between its jaws. The bolts must, of course, be short enough to permit this pressure.

An Aid to Petrol Borrowing.

A. BUS driver-inspector, " F.A.W.," of Southampton, sends us a tip which he has found of use should a driver run short of petrol and want to draw enough from another man's tank to enable him to get to his depot, or to some place where a fresh supply can be obtained.

His suggestion is that every driver should be provided with a syringe to hold about a pint or more of petrol, with which he could draw out of a tank what he requires, without having to find some utensil to carry it in.