FORD HINTS AND TIPS.

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS NEW series of Hints and Tips concerning the Ford light chassis and ton trucks wherever they are employed for commercial purposes, which commenced in our last issue, we propose to deal with the subject from every viewpoint, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information will be tapped for this purpose, and it should be understood that the information given will all be derived from those with a practical and intimate knowledge of the subject.

We shall welcome for inclusion amongst the hints those which have proved of value to individual users, and will make suitable remuneration for any published. What we desire are the results of practice, and not so-called improvements, which are but theoretical.

Continuing with breaking (spelt with an drivers often cause themselves quite a considerable amount of trouble by breaking off short the cylinderhead studs. One frequent cause of this is that small particles of carbon fall into the stud-holes during the process of decarbonization, and when attempts are made again to screw the stud home they break off and must then be drilled out and the holes retapped, for it is hardly likely that the broken piece can be extracted in the ordinary way as it will be 60 thoroughly jammed, or, rather carboned," at its lower end.

To avoid all this work—and the Ford driver usually has quite enough to do on his round without making any extra work on the vehicle—after decarbonizing, each stud-hole should be cleaned out by means of a twist drill of a size 1-64th in, under the inner diameter of the threads, so that there is no risk of injuring them.

A second cause of breakage is pulling down the studs too tightly. This would seem obvious, but it is surprising how often it is done, as it is only with continuous practice that a man who is not gifted with that fine sense of touch which enables him to feel the limiting strength of a bolt can use a spanner for tightening studs or nuts to the maximum point of tightness consistent with safety.

7.—Where Not to Use Oil.

We regret that we have now to bring our, we trust, patient readers back to the subject of oil. In this case it is "where oil should be avoided." We are not referring to clothing or hands, but to those parts of a Ford where the use of oil is deleterious.

Always use grease for the back axles whether thee be of the bevel or worm-driven type. Oil quickly softens the felt washers at the end of the axle and, escaping through the wheel bearings, bespatters the

tyres, and these, in the matter of Oil, can be classed as conscientious objectors,4 If the oil ever does rest on the rubber for any appreciable length of time it soon rots it. This is a tip whieh should be remembered when the vehicle is standing. in the garage, for far too often puddles of oil and grease are to be seen all over the floor, and here the poor, long-suffering tyres have to rest, instead of being at their ease in a nice cool, dry spot. •

8.—Finding Cracks in Crankshafts.

Our oil gusher is not yet exhausted, and here is a method of using paraffin in order to find if there are any cracks in a Ford crankshaft. in the ordinary course these cracks are almost invisible, although they are a fairly common fault. To find them, soak the crankshaft in paraffin for a short time and then carefully dry it off round the journals and the parts of the crankshaft in their vicinity. Now, if the webs are given a fairly sharp blow, with a hammer, the paraffin in any crack will be jerked out and can then readily be seen. A similar object can be achieved if one end of the crankshaft be held in the hand and the other dropped with a thud on the floor. The paraffin shows itself as a thin streak. It is hardly worth while repairing crankshafts as they can be replaced for a few shillings.

9.—Why the Carburetter is Sometimes Starved.

Having already mentioned oil and paraffin, we will get on to a lighter topic and deal with petrol. If trouble be experienced owing to a poor feed to the carburetter, this will probably be due to sediment in the bulb, to a kink in the pipe, or airlocks. The lastnamed are of frequent occurrence, and the cure is to disconnect the pipe at the carburetter end and to blow through the tank. It is advisable to take a deep breath before doing this, as petrol fumes are somewhat di,staateful. Cures for the other two faults are obvious—clean the bulb and " unkink " the pipe ; in any case the matter should be attended to at once, for it does not pay to starve the ox that treads the corn.

10.—Adfusting the Clutch.

In order to overcome the trouble of a slipping clutch which causes the vehicle to shy at hills, except when in low gear, and sometimes even then, it will be necessary to adjust the finger pins. To do this, re-move the split-pins ; half a turn on each with a screwdriver should be sufficient to overcome the trouble. Of course if, instead of slipping, the clutch has proved too fierce, turn the screws in the opposite direction. Be most careful to replace the split-pins.

11.—Strengthening Springs for Bigger Loads.

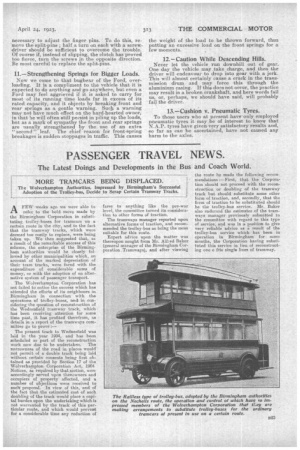

Now we come to that bugbear of the Ford, overloading. It is a compliment to the vehicle that it is expected to do anything and go anywhere, but even a Ford may feel augrieved if it is asked to carry for most of its running time loads far in excess of its rated capacity, and it objects by breaking front and rear springs as a gentle warning. Such a warning may not have much effect on the hard-hearted owner, in that he will often still _persist in piling up the loads, but as a mark of sympathy the front and rear springs are usually strengthened by the. use of an extra " second " leaf. The chief reason for front-spring breakages is sudden stoppages in traffic. This causes the weight of the load to be thrown forward, thus putting an excessive load on the ft out springs for a few moments.

12.— Caution While Descending Hills.

Never let the vehicle run downhill out of gear. One day the vehicle may . take charge, and then the driver will endeavour to drop into gear with a jerk. This will almost certainly cause a crack in the transmission drum and may force this through the aluminium casing. If this does not occur, the practice may result in a broken crankshaft, and here words fail us, or, perhaps, we should have said, will probably fail the driver.

13.—Cushion v. Pneumatic Tyres.

To those users who at present have only employed pneumatic tyres it may be of interest to know that N.A.P. tyres have given very satisfactory results and, so far as can be ascertained, have not caused any harm to the axles.