MAKING BEST USE OF THE FORD.

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which Will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer or mechanic. We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any such information which we publish. Readers are recommended to obtain the original " Book of the Ford," which constitutes a complete manual dealing with the Ford car, the van and the truck. 2s. 9d. post free from the offices of this journal.

24L—A Stay for the Ford Engine.

The power unit of the Ford is suspended in the chassis at the point of balance by two pressed steel arms, and at the rear of these there is an overhang of about 16 ins. It is here that the greatest stresses occur, often resulting in the breaking off of the crankcase arms.

When starting en a hill, the drive shaft tries to lift the engine, and the reverse occurs when the brakes are applied. This is apart from the twisting stresses.

At all times the weight of the torque tube is considerable, and this is accentuated if a gearbox be fitted at the front end.

In order to overcome the trouble of broken arms, J. T. Greenwood, of Burnley Road, Colne, Lanes., has devised a special strengthening attachment known as the Super-Stay. This bridges the frame and is provided with a plate which encircles the torque ball casing, so that the stresses are conveyed direct to the frame instead of through the crankcase, whilst the method of fitting is such that the principle of three-point suspension is not upset. The price of the device is only 30s., and it is provisionally protected.

242.—Obtaining More Wear from the Rear Brake Linings.

One of our readers, having occasion to adjust the rear brakes of his ton truck, found that further adjustment on the rods was not possible, and yet the linings at the thinnest places were not less than in. thick.

The vehicle was wanted urgently and, consequently, there was no time to reline the shoes, but he happened to have a pair of split steel bushes for the steering spindle arms, and after unscrewing the brake shoe bolts, one hush was sprung on to each, a washer placed against the bolt head and the bolts again screwed into position, after which. the shoes were adjusted by slacking back the rods.

This method gives a longer life to the friction material, and when the shoes require relining the bushes can easily be removed and the brake restored to its original condition.

243.—Repairing a Ford Crankcase by Oxy.. Acetylene Welding.

In some repair shops where oxy-acetylene welding devices are installed, it is the most satisfactory method to employ for repairing Ford crankcases., as the fractured or cranked parts can be perfectly united and great strength secured by reinforcing the weld.

Briefly, the process consists in chipping a triangular groove of the width and depth of the crack, and filling this groove with molten Swedish iron of the best quality.

The use of a flux is not necessary in welding steel, and after the completion of the repair the welded part should be annealed by heating to cherry-red and allowing it to cool gradually.

244.—A New Type of Detachable Transm:ssion Band.

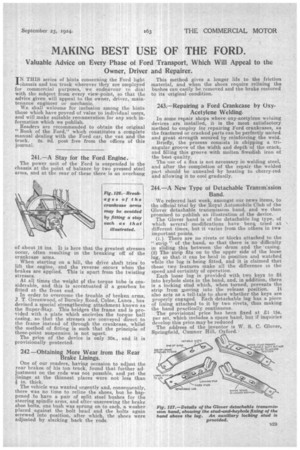

We referred last week, amongst our news items, to the official trial by the Royal Automobile Club of the Glover detachable transmission band, and we then promised to publish an illustration of the device.

The Glover band is of the detachable lug type, of which several modifications have beeii tried at different times, but it varies from the others in two important points,

(I.) There are no rivets or blocks attached to the " strip " of the band, so that there is no difficulty in sliding this between the drum and the 'casing. (2) The strip. fits on to the upper side of the loose lug., so that it can be heid in position and watched while the lug is being fitted, and it is claimed that these two features make all the difference in the speed and certainty of operation.

i Each loose lug s provided with two keys to fit into keyhole slots in the band, and, in addition, there is a locking stud which, when turned, prevents tbe strip from gloving into the release position. It also acts as a tell-tale to show whether the keys are properly engaged. Each detachable lug has a piece of lining attached to it by two rivets, thus making the band practically continuous. The provisional price ha 8 been fixed at 21 15s. per set, which includes a spare band, but if inquiries develop this price may be reduced

The address of the inventor is W. S. C. Glover, Springfield, Cumnor Hill, Oxford.,