The Comme Bridge: Lorimer

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

e Gap

By Anthony Ellis

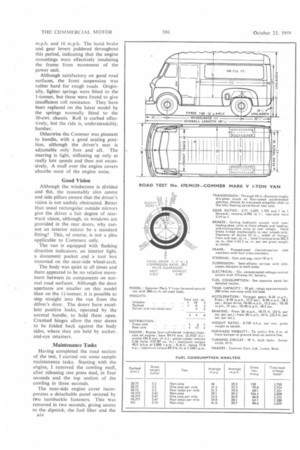

TO fill the gap in their range between the Superpoise 15-cwt. chassis and the 14-tonners, Commer Cars, Ltd., have produced a 1-ton version of their 1+-ton forwardcontrol chassis, The major difference between the smaller and larger models lies in the wheelbase, which has been . shortened by 1 ft. without altering the front and rear overhang.

Lighter springs are fitted at the rear and 7.00-16 (8-ply) tyres are used. As in the 14-tonner, either the Rootes four-cylindered petrol engine or the four-cylindered indirect-injection oil engine is offered. Both units have a capacity of 2.26 litres. The petrol engine develops 56 b.h.p. at 3,400 r.p.m. and 104 lb.-ft. torque at 1,600 r.p.m. and the oiler, 48.5 b.h.p. at 3,000 r.p.m. and 89.5 lb.-ft. torque at 1,500 r.p.m. A higher-rated version of the oil engine is offered for arduous operation.

With an oil engine the standard van costs £843, or with petrol engine. £723.

The synchromesh gearbox is identical to that fitted in the 14-tonner, but the rear-axle ratio is raised to 5.14 to 1, whereas a 5.57 to 1 ratio is used in the larger model.

In constructing the 280-cu-ft. allsteel van body, maximum use has been made of existing pressings. The roof panels. suitably cropped, are from the 300-cu.-ft. body normally fitted to the 14-ton chassis, whilst the body side panels from the larger van are incorporated without obvious modification; the extra length merely reduces the opening for the sliding doors.

The standard van provided for test was an oiler. When introduced some e 1 2 three years ago, the engine was the first production unit in this country to be fitted with the C.A.V. distributor-type fuel pump. Although some teething troubles were experienced in the early days, this simple and effective pump has now built up a reputation for reliability.

The van weighed 1 ton 18+ cwt. unladen; 1 ton 01 cwt. of sand bags and iron weights was added to bring the weight up to 2 tons 191 cwt., which, with myself and two Commer representatives aboard, made the gross weight 3 tons 4 cwt.—a 2-cwt. overload on the manufacturer's gross rating of 3 tons 2 cwt.

As this degree of overload would probably be the rule rather than the exception in service, I did not remove any of the load. It is noteworthy that, although nominally a 1-tonner, the van can carry 1 ton 3} cwt., including the driver, yet remain within the recommended gross rating.

A graduated test tank was fitted before making a fuel-consumption run on our familiar six-mile course between Barton and Clophill on the A6 road. On this representative, undo

lating circuit an average speed of 30 m.p.h. was aimed at for the non-stop runs. During the stopping runs, the engine was left idling for 15 seconds at each halt.

Road conditions varied markedly during the three hours which it took to complete the seven runs and were reflected in the figures obtained. There was little traffic during, the non-stop run at full load, which allowed the exceptional figure of 40 m.p.g. to be returned.

This was 0.9 m.p.g. better than the figure achieved with half the payload removed when the same average speed was maintained in heavier traffic. I think 40 m.p.g. with full load is rather better than would be achieved in service at average speeds in the order of 30 m.p.h.; a more likely figure is about 38 m.p.g., which is, nevertheless, satisfactory.

I attempted next to test the brakes and was forcibly reminded that sunsoftened tarmacadam surfaces can be as slippery as wet ones; full-pressure brake applications from 20 m.p.h. provoked violent skidding and gave stopping distances of more than t. Brake testing was accordingly postponed until a cooler we could be found.

4ch heat seemed ideal for assessing the efficiency of the ing system. At the foot of Bison Hill, near Whipsnade, ambient temperature was 91° F. and the coolant tempera 174° F. The climb, which has an average gradient in 101, was made in 3 minutes 25 seconds with first gear se for 8 seconds.

ad T not delayed the change from third to second gear, kg road speed, the van would have made the ascent without rt to the lowest ratio. The water temperature after the b had risen by only 6° F.—a very good performance from m-pressurized system on such a hot day.

s the 1-tonner has an identical braking system to the )nner, it should have exceptional ping power with spare braking :t to allow for fade and similar ictions in efficiency. To ascertain her this was so, I coasted down the in neutral, restricting the speed to a.p.h. with the foot brake. As the [lent decreased towards the bot

of the hill, top gear was engaged the vehicle driven at full throttle nst the brakes to maintain the a speed.

he complete descent occupied 2 utes 30 seconds, with 32 seconds Lt in top gear. A full-pressure :e application from 20 m.p.h. proxi the astounding reading on the Icy meter of 100 per cent. although brake pedal almost touched the rboards. Earlier the meter had red slightly erratic and the reading rded was obviously not true. How, during the stop all the wheels ed and there was clearly little iction in braking effect through Ideed, the DM8 moulded facings loyed are claimed to increase ktly in efficiency when heated. The

• ee of drum expansion which took e was obviously severe, even wing for the high ambient ternlure, and some alteration in the gn of the 12-in.-diameter castings in the material used for them ht reduce it. Full pedal travel was vered in less than two minutes there was no smoke or smell of

• heating from the facings thems.

eturned to the I in 6 section of hill. the van was held easily on hand brake. Restarts in bottom were made without slipping the 11, although the vehicle would get away in second gear. The theoretical maximum gradient ability of the 1-tonner is 1 in 4 and at the weight at which it was tested, I would assume that it could be restarted without difficulty on at least a 1 in 5 slope,. During these tests no excessive exhaust smoking was noticed, even when the engine was labouring at full throttle in second gear.

An early start next morning • produced a satisfactory surface on whi.:•.h to obtain braking figures on a section of the North Orbital Road. The Girling system employed is powerful and pleasantly progressive, requiring only light pedal pressures for normal retardation.

Straight-line Braking On the slightly polished road used for the test, the vehicle pulled up in a straight line with all wheels locked on all occasions both from 20 m.p.h. and 30 m.p.h. Even better figures than those obtained would have resulted from similar tests on a roughsurfaced road.

Although the lever is not ideally situated—when applied, it is rather far back in relation to the driver's seat-the hand brake produced an average reading on the Tapley meter of 43.5 per cent. from 20 m.p.h. Doubts as to the accuracy of this reading were dispelled when 1 measured the skid marks (only the off-side rear wheel locked during these tests), and found

them to average 30 ft. As there would be no delay in the system. this figure tied in well with the meter reading and shows the hand brake to be really effective.

The North Orbital Road was employed also for acceleration tests. Each figure quoted in the data panel is the mean of one run in each direction. •

David Whitten, of Commer, handled the vehicle during these runs, as 1 found the synchromesh on the three upper gears rather heavy, hampering fast gear-changing by one not used to the vehicle. Starting in first gear for all the through-the-gears runs the van reached 30 m.p.h. in 17.5 seconds. Acceleration then tailed off rather, as a further 21 seconds were required to attain 40 m.p.h. Maximum speeds in the gears were found to be: First, 10 m.p.h., second, 20 m.p.h., and third, 34 m.p.h. As the maximum speed is just over 50 m.p.h., the overall gear ratios with the 5.14 to 1 ratio axle fitted are well split for normal operation.

Considering that the Rootes oil engine runs up to 3,000 r.p.m., the van was surprisingly tractable in top gear, running at slightly under 10 m.p.h. in this ratio without distress. From this speed the acceleration was constant in increments of approximately 15 seconds for each gain in speed of 10 m.p.h. up to 40 m.p.h.

Slight vibration was felt between 12 B13 m.p.h. and 16 m.p.h. The hand brake and gear levers juddered throughout this period, indicating that the engine mountings were effectively insulating the frame from movement of the power unit.

Although satisfactory on good road surfaces, the front suspension was rather hard for rough roads Originally, lighter springs were fitted to the 1-tonner, but these were found to give insufficient roll resistance. They have been replaced on the latest model by the springs normally fitted to the 30-cwt. chassis. Roll is curbed effectively, but the ride is, understandably, harsher.

Otherwise the Commer was pleasant to handle, with a good seating position, although the driver's seat is adjustable only fore and aft. The steering is light, stiffening up only at really low speeds and then not excessively. A muff over the engine covers absorbs most of the engine noise.

Good Vision

Although the windscreen is divided and flat, the reasonably slim centre and side pillars ensure that the driver's vision is not unduly obstructed. Better than usual rectangular outside mirrors give the driver a fair degree of rearward vision, although, as windows are provided in the rear doors, why cannot an interior mirror be a standard fitting? This, of course, is not a plea applicable to Commers only.

The van is equipped with flashing direction indicators, an interior light, a document pocket and a tool box mounted on the near-side wheel-arch.

The body was quiet at all times and there appeared to be no relative movement between its components on normal road surfaces. Although the door apertures are smaller on this model than on the 11-tonner, it is possible to step straight into the van from the driver's door., The doors have excellent positive locks, operated by the normal handle, to hold them open. Cranked hinges allow the rear doors to be folded back against the body sides, where they are held by socketand-eye retainers.

Maintenance Tasks

Having completed the road section of the test, I carried out some sample maintenance tasks. Starting with the engine, I removed the cowling muff, after releasing one press stud, in four seconds and the top section of the cowling in three seconds.

The near-side engine cover incorporates a detachable panel secured by two turnbuckle fasteners. This was removed in two seconds, giving access to the dipstick, the fuel filter and the B14 :tion pump. The cover can be ched without taking off the muff. aving done this. I checked the ne oil level with the flexible dipin 15 seconds. The bowl of the V. paper element fuel filter, the filter in the system, was removed replaced after inspecting the dcin 3 minutes 50 seconds: allow the filter bowl to be drawn through • the side panel it was ssary to remove the inlet pipe to filter to give sufficient clearance. flat spanners provided in the lard tool kit would not fit the ring nut on top of the filter or banjo bolts on the fuel line. ough the adjustable spanner in the vould have sufficed, it is not the tool for this sort of work.

injector was then removed in 3 nes 20 seconds, but I was fortuin that the injector had been in lead for only 800 miles and was easily withdrawn. I replaced it in nutes after experiencing difficulty nking up the inlet and overflow ;.

bile carrying out this task I spilt 'uel on the rubber sealing strip minding the top flange of the engine cowling. It promptly detached itself from the metalwork, indicating that a Derv-resistant adhesive would be an advantage.

Bleeding the fuel system can be rather involved. To be performed thoroughly it necessitates attention to seven bleeding points; the air filter, two unions on the fuel pump and the four injectors. The task is complicated by the difficulties of getting a spanner anywhere near one of the unions on the fuel pump and of releasing the injector feed pipes without first removing the overflow pipes.

I left this operation to the Commer service department, who had the engine running in 25 minutes. I was told that bleeding can take anything from 15 minutes with luck to half a day without this valuable commodity. The task could certainly be simplified by tidying up the injection system in general.

After noting that the air cleaner was mounted accessibly on top of the engine and that the Purolator oil filter could be reached only from underneath the vehicle, 1 turned to maintenance of the chassis.

Forty-five seconds sufficed to inspect the gearbox oil level. This operation was carried out in the cab with a dipstick covered by a rubber plug in the floor. A similar plug in the driver's toe board reveals, when removed, the hydraulic fluid reservoir for the braking system. It took 35 seconds to check its level.

The level plug for the rear axle is situated in the differential cover pan at the rear. It is loosened by means of a large Allen key and was removed and replaced in 65 seconds.

To adjust the rear brakes, I jacked both rear wheels up together with the screw-type jack provided in the tool kit. This proved hard and rather slow work and more normal practice, when the vehicle is fully laden, would be to jack the wheels up separately.

Once the wheels were clear of the ground the single square-headed adjusters on the back plates presented no difficulty. Both brakes were adjusted in 8 minutes 40 seconds. I did not take up the front brakes. Had I done so they would have required less time than the rear brakes, even though there are two adjusters to each brake, because the front-axle loading is lighter.