The All-light-met al Lorry a Practical Proposition

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

IN the immediate pre-war years, considerable interest was being taken in the use of high-strength light alloys in the construction of commercialvehicles. In most cases, however, they were applied more extensively to bodywork than to chassis, whilst attempts to build complete vehicles, using light alloys wherever possible, were rare.

Considering the limitations imposed by statute on the unladen weight of vehicles, and the restriction of speed on those weighing, at that time, over 50 cwt., it is perhaps surprising that even greater attention was not paid to the obvious advantages to be gained by the wider use of light alloys.

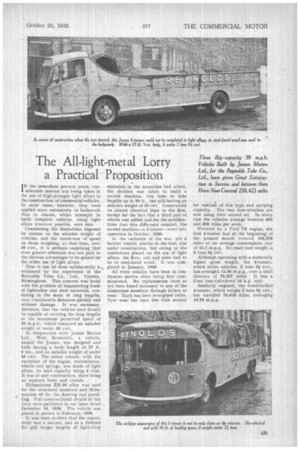

' That it can be done satisfactorily is, evidenced by the experience of the Reynolds Tube Co., Ltd., Tyseley, Birmingham. This concern was faced with the problem of transporting loads of light-alloy and steel materials, consisting in the main of long lengths, over considerable distances quickly and without damage. It was necessary, therefore, that the vehicles used should be capable of carrying the long lengths at the maximum permitted speed of 30 m.p.h., which connoted an unladen weight of under 50 cwt.

In Conjunction with Jensen Motors Ltd., West Bromwich, a vehicle. named the Jensen, was designed and built having a body length of 27 ft. S ins., and an unladen weight of under 50 cwt. The entire vehicle, with the exception of the engine, transmission, wheels and springs, was made of lisht alloys, its load capacity being 4 tons. It was of unit construction, there being no separate body and chassis.

Hiduminium RR.56 alloy was used for the structural members and Hiduminium 45 for the flooring and panelling. Full constructional details of this lorry were published in our issue dated December 16, 1938. The vehicle was placed in service in February, 1939.

It was soon evident that the experiment was a success, and as a demand fbr etill longer lengths of light-alloy materials in the meantime had arisen, the decision was talem to build a second machine, this time to take lengths up to 30 ft., bitt still having an unladen weight of 50 cwt. Constructed on almost identical lines to the first, except for the fact that a third pair of wheels was added and for the modifications that this difference entailed, the second machine—a S-tonner—wen t into operation in October, 1999.

At the outbreak of the war, yet a further vehicle, similar to the first, was under construction, but owing to the restrictions placed on the use of light alloys, the floor, cab and sides had to be of steel-faced wood. It was completed in January, 1940.

All three vehicles have been in continuous service since being first commissioned. No replacements have as yet been found necessary to any of the aluminium members through failure or wear. Each has been re-engined twice. Tyre wear has been less than normal for vehicle; of this type and carrying capacity. The two four-wheelers are now using their second set. In every case -the vehicles average between 600 and 800 miles per week, Powered by a Ford V8 engine, the first 4-tonner had at the beginning of the present month covered 100,578 miles at an average consumption rate of 12.1 m.p.g. Its exact tare weight is 2 tons 61 cwt.

Although operating with a materially higher gross weight, the 5-tonner, which scales unladen, 2 tons si cwt., has averaged 12.56 m.p.g., over a total distance of 75,227 miles. It has a Ford four-cylindered 24 h.p. unit.

Similarly engined, the wood-bodied 4-tonner, which weighs 2 tons 131 cwt., has travelled 74,618 miles, averaging 13.78 m.p.g.