Drivers &Mechanics

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send us an account of any special incident of your work or experience. If suitable, we will edit your notes, supply a sketch when required, and pay you for everything published. Mention your ensfiloyer's name, in confidence, as evidence of good faith. Address to The Fditor, THE COM"NIERCIAL MOTOR, Rosebery Avenue, London, EC.

Light Up Your Lamps At — 5.50 on Thursday ; 5.48 on Friday ; 5.46 on Saturday; 5.42 on Monday ; 5.40 on Tuesday ; 5.38 on Wednesday.

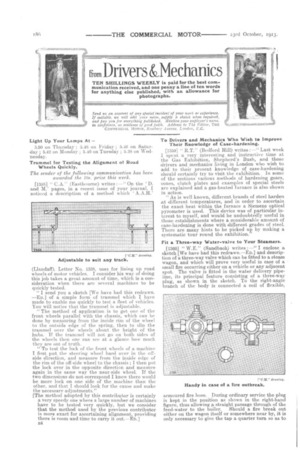

Trammel for Testing the Alignment of Road Wheels Quickly.

The sender of the following communication has been awarded the los. prize this week.

[13581 " C.A." (Eastbn.urne) writes :—" On the 'P. and M.' pages, in a recent issue of your journal. I noticed a description of a method which A.A.H.'

(Llandaff), Letter No. 1338, uses for lining up road wheels of motor vehicles. I consider his way of doing this job takes a great amount of time, which is a consideration when there are several machines to be quickly tested.

"I send you a sketch [We have had this redrawn. —En.] of a simple form of trammel which I have made to enable me quickly to test a fleet of vehicles. You will notice that the trammel is adjustable.

"The method of application is to get one of the front wheels parallel with the chassis, which can be done by measuring from the inside rim of the wheel to the outside edge of the spring, then to slip the trammel over the wheels about the height of the hubs. If the trammel will not go on both sides of the wheels then one can see at a glance how much they are out of truth.

" To test the lock of the front wheels of a machine I first put the steering wheel hard over in the off side direction, and measure from the inside edge of

the rim of the off-side wheel to the chassis ; I then put the .lock over in the opposite direction and measure

again in the same way the near-side wheel. If the two dimensions do not correspond I know there would be more lock on one side of the machine than the other, and that I should look for the cause and make the necessary adjustments."

[The method adopted by this contributor is certainly a very speedy one where a large number of machines have to be tested very quickly, but we consider that the method used by the previous contributor is more exact for ascertaining alignment, providing there is room and time to carry it out.—ED.] To Drivers and Mechanics Who Wish to Improve Their Knowledge of Case-hardening.

[1359] "R.T." (Bedford Hill) writes :—" Last week I spent a very interesting and instructive time at the Gas Exhibition, Shepherd's Bush, and those drivers and mechanics living in London who wish to add to their present knowledge of case-hardening should certainly try to visit the exhibition. In some of the sections various methods of hardening gears, cones, clutch plates and examples of special steels are explained and a gas-heated furnace is also shown in. action.

'As is well known, different brands of steel harden at different temperatures, and in order to ascertain the exact heat within the furnace a Siemens optical pyrometer is used. This device was of particular interest to myself, and would be undoubtedly useful in those establishments where a considerable amount of ease-hardening is done with different grades of steel. There are many hints to be picked up by making a systematic tour round the exhibition."

Fit a Three-way Water-valve to Your Steamers.

[1360] " W.E." (Sandbach) writes :—" I enclose a sketch [We have had this redrawn.—En.] and description of a three-way valve which can be fitted to a steam wagon, and which will prove very useful in case of a small fire occurring either on a vehicle or any adjacent spot. The valve is fitted in the water delivery pipeline, its principal feature consisting of a three-way plug, as shown in the sketch. To the right-angle branch of the body is connected a coil of flexible, armoured fire hose. During ordinary service the plug is kept in the position as shown in the right-hand figure, thus allowing a. straight passage through of the feed-water to the boiler. Should a fire break out either on the wagon itself or somewhere near by, it is only necessary to give the tap a quarter turn so as to

bring the ports of the plug in position as shown in the lower sketch. Tilts will then shut off the passage of water to the boiler and deflect it into the fire hose, which, of course, is fitted with a suitable jet at its extremity. The flexible hose should be always connected up to the valve and rolled up in a coil, and hung up in a handy place on the wagon ready for immediate use. I think drivers of steam-wagons would do well to fit one on their machines. It is not costly to procure, or the valve itself may he made if the suitable tools be at hand, and the arrangement is very useful to have in readiness in case of fire."

Making a Drilling Block Out of an Old Crankshaft.

[1361] "ix. " (Cardiff) writes :—" A most handy packing or drilling block can be made from a discarded crankshaft. The cheeks are of course planed quite parallel, thus making this portion of the shaft particularly suitable for the purpose. " I send you a sketch [We have had this redrawn.En.] showing such a block which I have put into use from an old four-cylinder crankshaft which was knocking about the shop. The journals are sawn off so that each cheek can be utilized on the table of the drilling machine. The remaining cheeks can be cut up and used on a shaping machine as packing strips. " The block, as illustrated, is specially suited for drilling light bentwork and the raised portion enables the bent portion of the work to clear during the operation of drilling. A spring clip is just the thing for clamping the block on to the machine table."

Repairing a Leaking Radiator Tube Block.

[1362] " (Llandaff) writes " I have noticed from time to time. on machines which come into our garage for repairs the very shoddy way in which leaky radiator tube blocks are stopped up. Sometimes two small brass plates have been cut out and fitted over the leaking portion of the honeycomb one being fitted to the front and one to the back of the tube block and clamped together by means of a small bolt passimg right through the radiator, rubber insertion having been put bet si een the radiator and the plates.

" Another careless method one man had resorted to for stopping the leakage was by filling about 4 ills. area of the radiator with white lead ; he had also disfigured the index number to such an extent as to have been cautioned by the police. These are. but two instances showing the shoddy method with which some drivers try to stop such leaks.

" Now the method which I always carry out is as follows : --I take the radiator adrift from the chassis, find the exact place of the leak and mark it round with chalk. All grease and dirt is then thoroughly scraped away from around damaged part of the honeycomb. I fill the small tubes up with paper,

pressing it tightly inside the honeycomb to a depth of about in. from the face. This is done both at the back and front of the radiator. I then run solder into the damaged area. This makes a satisfactory joint, and also a clean repair.

" It can then be repainted, and does not interfere with the number or lettering in any way whatever. For a. leakage of more than 3 in. square the radiator should be sent to the manufacturer to be put right."

A Few Hints to Steam-Wagon Drivers.

[1303] " (Swindon) writes I am send ing one or two hints for your ' D. and M.' pages, thinking perhaps they will interest drivers of steamwagons. " Most driver-mechanics know, of ()nurse, how to set a slide-valve. There may be some, however, to whom a brief description of how I manage the job myself may be helpful. " Put the crankshaft alternately on its two dead centres, and measure the opening of the port to steam allowed by the slide-valve at each end of the stroke. When the measureme.nts are equal the ' lead,' and position, of the valve for each stroke is correct. The amount of opening of the admission port when the piston is at the beginning of each stroke is, of course, called the

" With regard_ to the boiler tubes, they should be cleaned about once a month so as to prevent choking up with soot and portions of clinker.

" Never use gritty packing, or you will score your rods.

" Keep the driving chain well lubricated but not excessively so.

" Do not leave ashes or clinker on the roadside, or you may get into trouble with the authorities and public: besides causing trouble for yourself it makes it had for your fellow drivers.

" Always use the correct size of spanner for your nuts and you will never round off the corners, which makes it difficult for them to be removed when a quick repair is necessary."

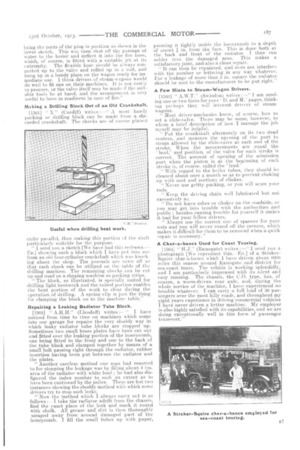

A Char-a-bancs Used for Coast Touring.

[1364] " (liamsgate) writes I send you a photograph [We reproduce this.En.] of a StrakerSquire char-asbancs which 1 have driven about 6000 miles this season around Ramsgate and dist jet for sea-coast tours. The vehicle is working splendidly, and I am particularly impressed with its silent and easy running. The chassis, the 0.0. type, has, of course, a worm-driven rear axle, and during the whole service of the machine, I have experienced no trouble whatever. I can carry a full load of 30 passengers over the most hilly roads, and throughout my eight years experience in driving commercial vehicles I have never driven a better machine. My employer is also highly satisfied with its capabilities, and we are doing exceptionally well in this form of passenger transoort."