Motor Road Rollers.

Page 14

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

A Few Notes Concerning Recent Progress at Queen Street Iron Works, Peterborough.

Our last article of moment in which reference was made to Barford and Perkins, Ltd., Queen Street Iron Works Peterborough, occurred a. little over four years ago, to be precise, on 22nd August, 1912. It is only to be expected that the company's progress since that date has been extensive. It would have been so apart from war conditions, but the recognition of the value of the motor roller in the war zones has tended further to improve the situation in respect of output. The motor road roller has made its advance in respect of general use side by side with the steam roller, and while replacing the latter in certain spheres for which its particular construction was better adapted, it has opened up new ,Aelds of use for mechanically-propelled rollers, and, in many cases, has made possible the easy levelling of surfaces which would otherwise have had to be finished by the slow, laborious process of rolling by horse-drawn rollers, or by the still slower and still more laborious manual effort.

The outstanding advantages of the internal-combustion-engined roller as compared with the older type employing steam as a motive power are undoubtedly those which it possesses in 'respect of its easily-conveyed fuel, the fact that it does not need frequent fresh supplies of water, and also its capability of being easily started and at short notice.

Permission to Fill Water Tanks Once

A couple of incidents, which, although perhaps in lighter vein, nevertheless serve to throw into high relief these special features of the motor roller, were related to us on the occasion of our recent visit to the works. The first obviously has no regard to current events. It concerns a contract entered into by a French company to make roads in Turkey and Turkeyin-Asia. It was at first decided to use, for the purpose of rolling these roads, the usual type of steam roller, and men were despatched to one of the scenes of operation in time to be able to re-erect the component parts of a roller which had been sent on in advance. After a lengthy delay, which was principally owing to the difficulty of conveying the heavy portions of the roller across a country only partially civilized—and it is interesting to note that the principal item which retarded progress in this regard was the boiler—the machine was eventually erected, and the contractors prepared to get to work. Coal was available at the cost of 25 a ton. No difficulty had been anticipated with regard to the water supply, as

a river ran close by. On the contractors sending down to this river to draw water, however, they were forbidden to do so as it was stated that the river supplied drinking water for the inhabitants of the district. Eventually, after a lengthy delay, permission was accorded them to fill the water tanks once and once only! The feelings of the contractors when awarded this permission can be better imagined than described.

When Coal is Scarce.

The other incident also relates to Overseas use of these rollers and comes from an engineer in the Straits Settlements. This man uses both steam and motor rollers. He works under difficult conditions, inasmuch as some of his roads are on the side of a hill and access to them is so difficult that the steam rollers, owing to the high location of the centre of gravity on these machines, occasionally tip over sideways. In the case of the petrol-driven machine, this difficulty does not exist owing to its low build. Again, the only fuel available for the steam rollers is timber. Timber, unfortunately, gets wet, and, consequently, it is by no means an uncommon occurrence for the engineer to arrive on the scene of any road-making operations only to find that the men, several hours after the normal time of starting, are not yet at work. in such circumstances he is met by the excuse that the wood is wet and the fire in consequence, will not burn. Here, again, the motor roller scores. Motor Rollers the Best in Certain Circumstances.

Neither of these instances, of course, could be taken seriously as indicating that the utility of the steam roller is on the decline, no raore than that the internalcombustion-engine driven machine can improve upon it in every case. They afford proof of the superiority of the newer type in certain circumstances.

One point in the design where the motor roller undoubtedly scores is in relation to the number and width of the rollers. By eliminating the boiler, the design can readily be adapted to the use of a single wide roller in the rear as well as in the front. This is an undoubted advantage, and has contributed largely to the success of Barford and Perkins's rollers, as well as others similar in design. There are many roads the foundations of which are such that they could not, without risk of possible damage, successfully be rolled by the standard type of steam roller having two comparatively narrow wheels at the rear.

Motor Rollers More Easily Manreuvred.

The motor roller is also particularly adaptable for use on work located at considerable distances from central depots, as the necessary bulk of fuel for protracted service can more easily be carried. In respect of its capability of manosuvring in narrow roads and on awkward corners, it shows again to advantage, owing to the shorter wheelbase, which is rendered possible by the elimination of the boiler from its c,on struction. These particular capabilities are useful when considered in conjunction with the possibility of having occasionally to roll short stretches of road, and when operating at street corners. It is possible in such a case to roll right up to the kerb and round the corner without having to tack two or three times on each occasion.

As regards the constructional features of these rollers, they were described in some detail in the article to which we referred in our opening paragraph. A few modifications and one or two slight improvements suggested in the course of lengthy experience, have been made, but as the design is very much the same as it then was, WeWill not weary our readers with a repetition. One point, however, which strikes us again as requiring emphasis is that relating to the springing.

Adequate Springing.

Each roller is fully sprung both as to its rear and front axles. The drive is transmitted through locomotive-type axle boxes sliding between guides, each axle box being carried by coil springs. The front end of the frame terminates in a massive casting, a recess in which covers the top of the pivot over the front roller. Two coil springs separate the pivot from this housing. They are located in recesses in the casting mentioned, one on each side of the pivot.

As might be expected, the company does not make its own engines, but purchases the power units from specialists. The engine employed on the smallest machine is a Gardiner, on the largest machines a four. cylinder White and Poppe is used ; on the others, that exceedingly popular and reliable Albion two-cylinder 16 h.p. engine supplies the power. They are all arranged so that they can utilize paraffin as a fuel.

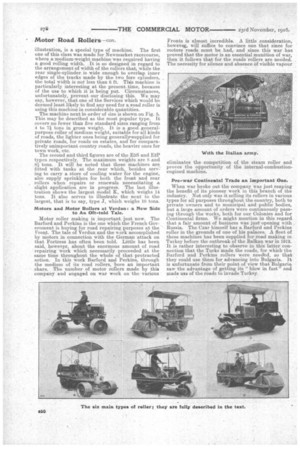

The company makes in all twenty different typesof roller, which 'are divided principally into six ,classes, each of which is shown on our composite illustration which appears on the next page, the smallest being tons, the largest 14 tons in weight. By different combinations it is possible to. arrange for almost any weight in between these two extremes. The need for all these types is due to the varying combinations of track-width, weight, etc., demanded by engineers and surveyors in various parts of the world. The most popular sizes vary between the limits of 4 and 8 tons respectively.

The Various Models Described.

The following descriptions read in conjunction with the illustration showing the six types will lot. fail to be of interest. The first figure is representative of types designated A2 and A3. The limits of the weight

of this class are and 2 tons, the rolling width being from 5 ft. to 6 ft. These machines are particularly. suitable for rolling lawns, light roads, paths, etc. The bottom left-hand figiare, No. 4 on the group

illustration, is a special type of machine. The first one of this class was made for Newmarket racecourse, where a medium-weight machine was required having a good rolling width. It is so designed in regard to the arrangement of width of the rollers that, while the rear single-cylinder is wide enough to overlap inner edges of the tracks made by the. two fore cylinders, the total width is not less than 6 ft. This machine is particularly interesting at the present time, because of the use to which it is being put. Circumstances, unfortunately, prevent our disclosing this. We may say, however, that one of the Services which would be deemed least likely to find any need for a road roller is using this machine in considerable quantities. The machine next in order of size is shown on Fig. 5. This may be described as the most popular type. It covers no fewer than five standard sizes ranging from 4 to 7 tons in gross weight. It is a good generalpurpose roller of medium weight., suitable for all kinds of roads, the lighter ones being generallyasupplied for private roads, for roads on estates, and for comparatively unimportant country roads, the heavier ones for town work, etc.

The second and third figures are of the E3S and E2P types respectively. The maximum weights are B and 81 tons. It will be noted that these machines are fitted with tanks at the rear which, besides serving to carry a store of cooling water for the engine, also supply sprinklers for both the front and rear rollers when repairs or renewals necessitating a slight application. are in progress. The last illustration shows the largest model K, which weighs 14 tons. It also serves to illustrate the next to the largest, that is to say, type J, which weighs 10 tons.

Motors and Motor Rollers at Verdun: a New Side to An Oft-told Tale.

Motor roller making is important just now. The Barford and Perkins is the one which the French Government is buying for road repairing purposes at the Froat. The tale of Verdun and the v. ork accomplished by motors in connection with the German attack on that Fortress has often been told. Little has been. said, however, about the enormous amount of road repairing work which necessarily proceeded at the same time throughout the whole of that protracted action. In this work Barford and Perkins, through the medium of its road rollers, bore an important share. The number of motor rollers made by this company and engaged on war work on the various Fronts is almost incredible. A little consideration, howevetc, will suffice to convince one that since for motors roads must be had, and since this war has proved that the motor is an essential munition of war, then it follows that for the roads rollers are needed. . The necessity for silence and absence of visible vapour eliminates the competition of the steam roller and proves the opportunity of the internal-combustionengined machine.

Pre-war Continental Trade an Important One.

When war broke out the company was just reaping the benefit of its pioneer work in this branch of the industry. Not only was it selling its rollers in various types for all purposes throughout the .cou.ntry, both to private owners and to municipal and public bodies, but a large amount of orders were continuously passing through the works, both for our Colonies and for Continental firms. We might mention in this regard that a fair amount of business was just' opening with Russia.. The Czar himself has a Barford and Perkins roller in the grounds of one of his palaces. A fleet of these machines has been supplied for road making in Turkey before the outbreak of the Balkan war in 1912. It is rather interesting to observe in this latter connection that the Turks made the roads, for which the Barford and Perkins rollers were needed, so that they could use them for advancing into Bulgaria. It is unfortunate from their point of view that Bulgaria saw the advantage of getting its "blow in fast" and made use of the roads to invade Turkey.