Coil ignition, 5

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

TICK OVER speeds, the spark the sparking plug must occur st before thee piston reaches Fe top of its compression roke, but it has been found that ; the engine is accelerated it is acessary to advance the ignion timing progressively, if aximum power is to be defloped.

In early vehicles, an advance ld retard lever was provided, .ivally in the middle of the eering wheel, to enable the iver to set the ignition timing • ;cording to engine speed and lad conditions.

It was essential to place the ver in the retard position when arting the engine by hand, therwise the engine would ackfire and the unfortunate river's wrist would, most likely, e fractured.

On all modern vehicles the igition is advanced and retarded Jtomatically.

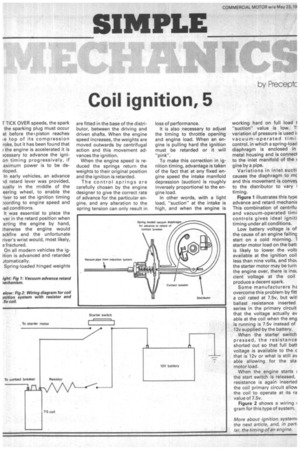

Spring-loaded hinged weights are fitted in the base of the distributor, between the driving and driven shafts. When the engine speed increases, the weights are moved outwards by centrifugal action and this movement advances the ignition.

When the engine speed is reduced the springs return the weights to their original position and the ignition is retarded.

The control springs are carefully chosen by the engine designer to give the correct rate of advance for the particular engine, and any alteration to the spring tension can only result in loss of performance.

It is also necessary to adjust the timing to throttle opening and engine load. When an engine is pulling hard the ignition must be retarded or it will "pink".

To make this correction in ignition timing, advantage is taken of the fact that at any fixed engine speed the intake manifold depression (suction) is roughly inversely proportional to the engine load.

In other words, with a light load, "suction" at the intake is high, and when the engine is

working hard on full load 1 "suction" value is low. TI variation of pressure is used il vacuum-operated timil control, in which a spring-load diaphragm is enclosed in metal housing and is connect to the inlet manifold of the gine by a pipe.

Variations in inlet sucti causes the diaphragm to mc and this movement is convey to the distributor to vary l timing.

Figure 1 illustrates this type advance and retard mechaniE This combination of centrifu and vacuum-operated timi controls gives ideal igniti timing under all conditions.

Low battery voltage is of the cause of an engine failinc, start on a cold morning. 1 starter motor load on the batt is likely to lower the voth available at the ignition coil less than nine volts, and thot the starter motor may be turn the engine over, there is inst cient voltage at the coil produce a decent spark.

Some manufacturers hz overcome this problem by fitt a coil rated at 7.5v, but witl ballast resistance inserted series in the primary circuit that the voltage actually av able at the coil when the eng is running is 7.5v instead of 12v supplied by the battery.

When the starter switch pressed, the resistance shorted out so that full batt voltage is available to the c that is 12v or what is still av able allowing for the sta motor load.

When the engine starts ; the start switch is released, resistance is again inserted the coil primary circuit allow the coil to operate at its ra value of 7.5v.

Figure 2 shows a wiring I gram for this type of system.

More about ignition system: the next article, and, in part far, the timing of an engine.