How important is accurate wheel balancing ?.

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

WHEN a truck can be driven at any speed without front wheel wobble, shimmy or excessive shake it is normally assumed that the steered wheels are well balanced. Any out-of-balance which exists is then thought to be so minor that it could not materially effect vehicle handling or cause damage to chassis components or bodywork by producing highor low-speed vibrations.

According to a technician of the service department of Fort Dunlop, Birmingham, operators rarely bother about balancing the front wheels unless a driver complains of wobble and that the vehicle is dangerous to drive. Undoubtedly, out-of-balance front wheels can accelerate wear and tear of tyre treads, joints and so on and hasten the onset of driver fatigue without influencing vehicle handling in an obvious way.

This being so, balancing the rear wheels might also be justified on economic grounds. So far it has been impossible to find an operator who worries about the back end. But that doesn't prove anything.

Demonstration

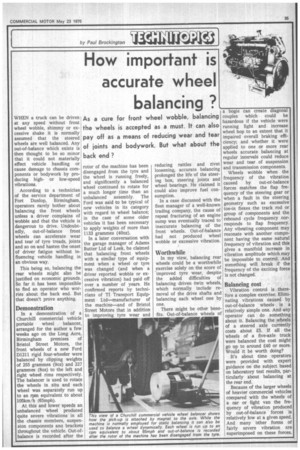

In a demonstration of a Churchill commercial vehicle portable wheel balancer, arranged for the author a few weeks ago on the Long Acre, Birmingham premises of Bristol Street Motors, the front wheels of a new Ford D1211 rigid four-wheeler were balanced by clipping weights of 255 grammes (9oz) and 227 grammes (Soz) to the left and right wheel rims respectively. The balancer is used to rotate the wheels in situ and each wheel was separately run up to an rpm equivalent to about 105km/h (65mph).

At this and lower speeds an unbalanced wheel produced quite severe vibrations in all the chassis members, suspension components ana brackets throughout the vehicle. Out-ofbalance is recorded after the rotor of the machine has been disengaged from the tyre and the wheel is running freely, and significantly a balanced wheel continued to rotate for a much longer time than an unbalanced assembly. The Ford was said to be typical of new vehicles in its category with regard to wheel balance; in the case of some older vehicles it has been necessary to apply weights of more than 1133 grammes (40oz).

In a later conversation with the garage manager of Adams Butter Ltd of Leek, he claimed that balancing front wheels with a similar type of equipment when a wheel or tyre was changed (and when a driver reported wobble or excessive vibration) had paid off over a number of years. He confirmed reports by technicians of TI Transport Equipment Ltd—manufacturer of the machine—and of Bristol Street Motors that in addition to improving tyre wear and reducing rattles and rivet loosening, accurate balancing prolonged the life of the steering box, steering joints and wheel bearings. He claimed it could also improve fuel consumption.

In a case discussed with the fleet manager of a well-known trading company, the cause of repeat fracturing of an engine sump was eventually traced to inaccurate balancing of the front wheels. Out-of-balance had not produced wheel wobble or excessive vibration.

Worthwhile

In my view, balancing rear wheels could be a worthwhile exercise solely on the score of improved tyre wear, despite the added difficulties of balancing driven twin wheels, which normally include removal of the drive shafts and balancing each wheel one by one.

There might be other benefits. Out-of-balance wheels of a bogie can create diagonal couples which could be hazardous if the vehicle were running light and increase wheel hop to an extent that it impaired overall braking efficiency; and whether it were applied to one or more rear wheels accurate balancing at regular intervals could reduce wear and tear of suspension and transmission components.

Wheels wobble when the frequency of the vibration caused by out-of-balance forces matches •the flap frequency of the steering gear or when a fault in the steering geometry such as excessive toe-in flexes the track rod or group of components and the rebound cycle frequency corresponds to flap frequency. Any vibrating component may resonate with another component having the same natural frequency of vibration and this gives a manifold increase in vibration amplitude which may be impossible to control. And something will break if the frequency of the exciting force is not changed.

Balancing cost

Vibration control is therefore a complex exercise. Eliminating vibrations caused by out-of-balance wheels is a relatively simple one. And any operator can do something about it. Balancing the wheels of a steered axle currently costs about £5. If all the wheels of a five-axle truck were balanced the cost might go up to around £40 or more. Would it be worth doing?

It's about time operators were provided with expert guidance on the subject •based on laboratory test results, particularly about balancing at the rear end.

Because of the larger wheels of heavier commercial vehicles compared with the wheels of a oar or light van the frequency of vibration produced by out-of-balance forces is relatively low at a given speed. And many other forms of fairly severe vibration are superimposed on these forces.