cheffield's Gas Makes Work for 70 Vehicles

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

By Ashley F. Taylor

THE history Of the Sheffield -gas' undertaking is closely linked with the industrial expansion of the City of Steel. In the gradually mounting totals from the annual production of 60,000,000 cubic ft. in 1844 to the 45,000,000-cubic-ft. daily "output of the present time, we can see the building up of the City, which first used gas for lighting alone, then for cooking and heating, and latterly for a variety of industrial processes as well. , The Sheffield and District. Gas Co. celebrated its centenary in November, 1944, although the first undertaking to manufacture gas in the city was formed as early as 1818. This first body was then known as the Sheffield Gas Light Co. and provided itself with a plant in Shude Hill. By all accounts, it failed to give satisfaction to the townspeople and, because of frequent complaints by consumers regarding the prices charged, a successful movement took place with the object of forming a rival concern.

The necessary application was made to Parliament and, after a lengthy hearing before committees of both Houses, the new Act received the Royal Assent in July, 1835, and so the Sheffield New Gas Co., with a capital of £80,000, came into being In 1844 the two companies were amalgamated by Act of Parliament under the title of the Sheffield Gas Light Co., this name being shortened in 1917 to the Sheffield Gas Co As time went on the undertaking spread far and wide, and in 1938 the title was changed once again, becoming the Sheffield and District Gas Co. Altogether, an area of 328 sq. miles is covered, stretching from Elsecar in the north to Cromford and Harlington in the south. The company has four main works in Sheffield, as well as plants at Matlock, Barnsley; Eckington, Dronfield and Elsecar.

Until 1913 horse-drawn vehicles, mainly hired from contractors, were used for the movement of materials, whilst the officials who desired to visit the various works either walked or travelled by public transport, except for the general manager, who could be .seen making his 'way from place to place by hansom cab. It was in 1914 that a transport department was set up, the first motor vehicle purchased being a Willys Overland. , Before the beginningof the 1914-18 war, three Armstrong-Whitworths and six Clement-Talbots had been acquired, all equipped with locally built bodies for the carriage of loads up to a ton. Then the Ford Model T came along to swell the fleet, and one of these vehicles was driven throughout the war period by the first woman motor driver in the city. From 1917 onwards the fleet grew rapidly, with the addition of Stars, Guys, and Wallis and Sentinel steamers.

At the same time, a small pool of private cars was being built up. for official use, the first being a Rover tourer, which was ,followed by a Leon Bolide 15 h.p. saloon. Next came real advance in the form of Wolseiey saloons.

Progress came to the goods fleet in the 'twenties in the shape of Morris-Commercial tonners, Beans and Guys. It is interesting to hear that, in the Sheffield works, a Bean and a Guy of 1927 vintage are still doing valiant service, unlicensed and operating solely on the company's premises in the movement of oxide and so on.

By. 1927 the fleet had grown to 30 vehicles, and it now includes some 70 load carriers, in addition to numerous cars. MT. W. Woodcock, Associnst.T., A.M.I.R.T E., transport and mechanical superintendent of the company, told me that since 1942 the commercial fleet has covered about 500,000 miles annually, whilst the cars run nearly 250,000 miles a year. Because of current shortages, restrictions on running are inevitable, and it will be appreciated that the approximate figures quoted are likely to show an upward trend in the future.

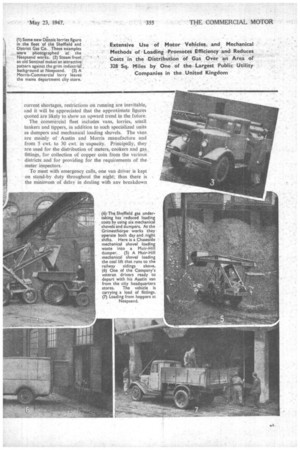

The commercial fleet includes vans, lorries, small tankers and tippers, in addition to such specialized units as dumpers and mechanical loading shovels. The vans are mainly of Austin and Morris manufacture and from 5 cwt. to 30 cwt. in -capacity. Principally, they are used for the distribution of meters, cookers and gas fittings, for collection of copper coin from the various districts and for providing for the requirements of the meter inspectors.

To meet with emergency calls, one van driver is kept on stand-by duty throughout the night; thus there is the minimum of delay in dealing with any breakdown in supplies. For this purpose a utility-type vehicle is used, specifically equipped for conveying men and materials to the scene of any emergency.

Unusual miniature tankers are another feature of this undertaking's fleet". Altogether, there are 10 of these machines (of Dennis andMorris-Commercial manufacture), and they work on a schedule which provides for daily visits to empty the syphon pots in the mains. By this means the pipes are kept free• from liquid, which would otherwise cause a stoppage in supply. The most recent unit acquired for this work is a MorrisCommercial with Butterfield 240-gallon tank and exterior panelling by Marston Excelsior, Ltd. A semirotary pump is used and is enclosed in a locker on the near side behind the cab.

A number of lorries is used for conveying pipes and other equipment for the mains department, and for towing compressors to breakdown and repair sites. Austin, Bedford and Dennis units are included among the 23 tippers, which are employed in delivering coke orders in Sheffield and neighbourhood, for the movement of waste from the works, and for the conveyance of coal and coke to the plants within the works area.

Mechanical Loading Reduces Costs' Loading costs have been greatly reduced by employing six mechanical shovels (mostly of Chaseside manufacture) and Muir-Hill dumpers. Mechanical shovels of i-cubic-yd. capacity are used throughout the company's works for loading road vehicles with coke and waste products, and for loading railway wagons with oxide. At the Grimesthorpe works mechanical shovels operate both day and night shifts, moving up to 150 tons of coal from the sidings to different elevators that feed the gas-manufacturing plants.

Dumpers are used at the Neepsend works, in addition to road vehicles, for the movement of coal and coke within the company's area. A narrow-gauge railway was laid down at this works five •years ago for the purposes of feeding gas-making plants and boilers; an Ailsa Craig Diesel locomotive with Dorman engine is employed. At the Grimesthorpe and Meadowhill works standard-gauge locomotives are in operation for similar purposes.

The transport and mechanical superintendents office, the stores, central repair shops, and painters' and joiners' shops are at present situated at the •Neepsend installation, which is conveniently located within about a mile of the centre of Sheffield.

The repair shop, measuring 100 ft. by 33 ft., is heated by hot-air fans, so that a comfortable working tempera1i6 ture is consistently maintained. Compressed-air lines lead to all the mechanics' benches and to the special high-pressure greasing bay. During the course of inspection it was interesting to observe that the narrowgauge railway track enters the shop on a raised platform for inspection purposes. Provision is also made for Sentinel steam wagons, employed on local work, to be inspected on the same platform.

Maintenance System Both the inspection and the dock-schedule systems are in operation. Commercial vehicles are taken into the repair shops every 8,000 miles and the scheduled overhaul is carried through. All work, except cylinder reboring and crankshaft regrinding, is performed by the company's staff. Spare power units are carried in stock for certain of the types operated and, if necessary, are fitted at the -first or second dock, the original engine later being reconditioned.

Dock schedule boards rare displayed in the transport and mechanical superintendent's office, total mileages being indicated by the insertion of coloured pegs, with pegs of different colours to indicate each service dock. A vehicle allocation board also shows the current location of each machine—whether at one of the depots or in the workshops. Detailed records are maintained which show the monthly mileage for each machine, together with its monthly fuel and oil consumption, dates of overhauls, mileages for brake adjustments, greasing and oil changes, together with other useful information.

A pre-arranged painting schedule ensures that the vehicles always present a smart appearance. The department employs one man specifically as a tyre fitter, and he is responsible for the inspection of every tyre of the fleet at least once a week.

Many Trusted Servants it is an eloquent tribute, not only to the loyalty of the company's employees but to the amicable -relations existing between management and staff, that many instances of long service can be quoted. The traffic foreman has spent 30 years with the company, one driver has 32 years' service, three have 31 years and 14 have over a quarter of a century.

The Sheffield alld District Gas Co. must be one of the largest public utility companies in the country, and there is ample evidence that its road transport fleet is organized with the object of giving every support to the undertaking in its endeavours to justify the claim that gas is really "Public Servant No. 1."