THE BOMB IN TOUR WORKSHOP

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

TYRE-CHANGING DANGERS ARE STILL TAKEN TOO LIGHTLY

CARELESSNESS and ignorance are still resulting in death or serious injury to fitters when removing wheels and changing tyres.

Some of the dangers were highlighted in a recent paper by two members of the Dunlop Tyre Technical Division who conducted an investigation into bursting tyres and wheels. It is a clue to the grim nature of their findings that the paper was presented to an international meeting of forensic scientists.

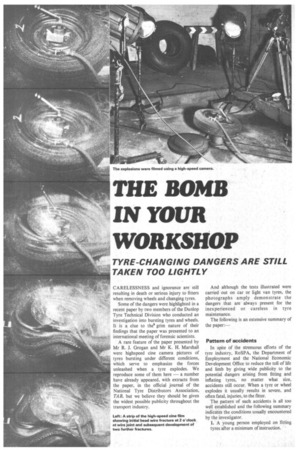

A rare feature of the paper presented by Mr R. J. Grogan and Mr K. H. Marshall were highspeed eine camera pictures of tyres bursting under different conditions, which serve to emphasize the forces unleashed when a tyre explodes. We reproduce some of them here — a number have already appeared, with extracts from the paper, in the official journal of the National Tyre Distributors Association, TAB, but we believe they should be given the widest possible publicity throughout the transport industry.

Left: A strip of the high-speed cine film showing initial bead wire fracture at 2 o'clock at wire joint and subsequent development of two further fractures.

And although the tests illustrated were carried out on car or light van tyres, the photographs amply demonstrate the dangers that are always present for the inexperienced or careless in tyre maintenance.

The following is an extensive summary of the paper:—

Pattern of accidents In spite of the strenuous efforts of the tyre industry, RoSPA, the Department of Employment and the National Economic Development Office to reduce the toll of life and limb by giving wide publicity, to the potential dangers arising from fitting and inflating tyres, no matter what size, accidents still occur. When a tyre or wheel explodes it usually results in severe, and often fatal, injuries, to the fitter.

The pattern of such accidents is all too well established and the following summary indicates the conditions usually encountered by the investigator.

I. A young person employed on fitting tyres after a minimum of instruction. 2. The absence of, or disregard of, safety cages or restraining devices.

3. An airline taken from a compressor without any form of pressure reducing valve, indicating gauge or remote control device.

4. A large, very much used tyre, or a wheel in poor condition. Taking these factors in order: 1. After serving a probationary period making the tea, sweeping up and running errands a young person is "promoted" to tyre fitting. He approaches the task with all the enthusiasm and self-assurance of youth but with little or no qualified instruction or training apart from the usual "Have 10 minutes with Bill, he'll show you how to do it" (and Bill himself was probably inadequately trained).

2. Many establishments do have safety cages in their fitting bays but, owing to shortage of space, bad siting and lack of proper safety training, they area put to more "important" uses such as storage of flaps, innertubes, discarded correspondence or slow moving stock. Restraining devices are rarely in evidence because they encumber the floor of the fitting bay. Any kind of safety device is usually considered a nuisance outside the tyre manufacturing industry.

Safety devices Tyre fitters employed within the industry invariably use safety devices, for two good reasons, (i) because they are aware of the potentially fatal consequences of a bursting unit and (ii) the regular inspection of all methods and equipment by the local safety officer ensures that the subject is always uppermost in fitters' minds. Another built-in safety factor is that in industry most tyres and wheels are new or little used unlike the local garage which has to deal with tyres that have been weakened by service, repairs and unskilled fitting and stripping. Wheels are very often badly corroded, have distorted fittings, and in many instances, have been modified or repaired by the local "do-it-yourself" expert.

3. Most garages have only one compressor. Consequently it is usually set at the maximum attainable pressure (180-200 psi). As reducing valves are another costly item and require maintenance they are not fitted. The airlines have a simple chuck-type inflation fitting, and it is all too easy for the fitter to clip on the inflation line and leave the tyre to inflate. Where an on /off control is fitted, the length of airline between the control and the valve connection is often so short that the fitter has no option but to crouch over the inflating unit or, more usually, to sit on it, so making the consequences of any burst much more serious.

Rear tyres worst 4. The type of tyre or wheel has an important bearing on the likelihood of a unit to explode. The rear tractive unit tyre seems to be the arch villain, and explosions with these tyres are all too common and the consequences nearly always fatal. The reasons are not difficult to establish. There is a natural tendency to equate size with strength. A rear tractive unit tyre looks rugged and it is difficult to accept that it is, in fact, little stronger than a car tyre, with a maximum safe inflation pressure of 40 psi. Because of its large volume any explosion which occurs is a severe one. Added to this, rear tractive unit tyres are rather more difficult to fit than any other tyres, because the deep well in the one-piece rim makes it comparatively easy for the bead to wedge on the shoulder of the well and to remain there until driven violently onto. the bead seat by the increasing tyre pressure. When this happens the bead, which by then has probably been weakened by kinking, fractures and permits an explosion.

Wheels with safety humps to prevent tyre dislodgement present a tricky fitting problem to the unskilled. To reach the bead seat, the tyre bead has to mount a raised hump. With reasonable care and adequate bead lubrication these wheels give little trouble.

However, if the fitter attempts to seat the bead by air pressure alone, and neglects to use lubricant, the bead can be restrained until the pressure is dangerously high and the bead finally locates with sufficient force to cause a fracture of the wires, and again an explosion results.

Another type of safety feature used on modern car wheels is the wide ledge. In this type of wheel the outer facing bead seat is much wider than usual, so giving an increased resistance to dislodgement of the tyre. It may seem obvious that the tyre must always be fitted or removed over the narrow ledge, but there are many occasions when tyres are damaged or the bead wires broken by a tyre being forced over the broad ledge.

Multipiece wheels The possibilities for the misuse of multipiece wheels are almost endless. Despite the care which manufacturers take to ensure the non-interchangeability of parts, we still encounter cases where wheels have fractured due to the use of incorrect lock rings or flanges. One• sees spring flanges which have fractured during demounting and the pieces have been re-assembled and used.

Sometimes the inner loose flange sticks unnoticed to the old cover and when a new cover is fitted the tyre is located against the loose flange retaining lip, where it retains the bead long enough for the tyre to be inflated to a high pressure before the lip fractures. In a few cases the wheel only fractures at a subsequent re-inflation.

The dangers of separating divided wheels with the tyre under pressure should, by now, be well known and yet accidents due to this cause still occur.

A puzzling factor in tyre explosions has been the unusual appearance of the exploded tyre. In all cases it is found that the bead wire has fractured in several places. Close examination of the ends of the wires reveals the ball-and-cup fracture typical of a tensile break. This appearance of several simultaneous fractures of the wire has puzzled investigators in this field for many years.

It seems improbable that every portion of the wire will have absolutely identical strengths particularly when one considers that the coil contains an overlap joint. One could argue, and indeed it has been argued in courts, that the wire will break at its weakest point and deflate the tyre without further damage. How then can the wire be broken in many places?

In order to investigate this paradox it was decided to burst tyres and to film the results. Initially a high-speed flashing light was synchronized to a normal eine camera. On examining the film it was obvious that the normal 24 frames /second was far too slow to capture the whole sequence of events in sufficient enough detail for close analysis. Accordingly a high-speed camera was used. This gave problems because the ordinary sunlight was not bright enough to enable a satisfactory image to be captured even on the fastest film. Ultimately 12--kW of lighting was used.

The Kodak 600 high-speed camera is shown trained upon the tyre surrounded by a battery of powerful lamps. The tyre is remotely inflated from a cylinder of low-moisture nitrogen and a pressureoperated switch is used to start the camera just when the tyre is about to burst. By this means we were able to obtain film of the tyre bursting without being obscured by condensed water vapour and with the camera running at a maximum speed of about 1000-1200 frames /second. At this speed the 100ft of film lasted 3+-4 seconds so that an accurate prediction of the burst was essential. In practice it was found that if the switch triggered the camera at 214 psi satisfactory results were obtained, the cross-ply 5.20-13 tyres bursting consistently at 240-250 psi.

Conclusions

As a result of investigations into tyre and wheel accidents and the use of the high-speed eine film we now have a clear idea of how a tyre or wheel explosion develops. Whether the lower or uppermost bead fractures is a matter of luck, much depending on the condition of the tyre or wheel and the way in which the tyre has been fitted. A lower-bead burst directs the air blast against the floor and the unit is propelled upwards. An upper-bead burst causes far less movement of the unit but the full force of the explosion is directed upwards, usually at the tyre fitter. Similar considerations apply to the vertical unit. This type of accident with attendant death or injury will continue until tyre fitters realize the inherent dangers of their job and adopt safe methods of working which must involve devices to restrain, or, beam still, enclose the unit during inflation.