HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best out of a Vehicle, to Secure Reliability and to Avoid Trouble.

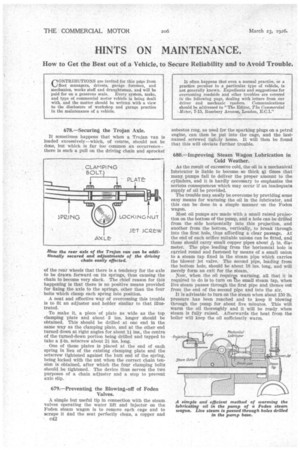

• 678.—Securing the Trojan Axle.

It sometimes happens that when a Trojan van is loaded excessively—which, of course, should not be done, but which is far too common an occurrencethere is such a pull on the driving chain and sprocket of the rear wheels that there is a tendency for the axle to be drawn forward on its springs, thus causing the chain to become very slack. The chief reason for this happening is that there is no positive means provided for fixing the axle to the springs, other than the four bolts which clamp each spring into position. A neat and effective way of overcoming this trouble is to fit an adjuster and holder similar to that illustrated.

To make it, a piece of plate as wide as the top clamping plate and about 3 ins, longer should be obtained. This should be drilled at one end in the same way as the clamping plate, and at the other end turned down at right angles for about 13 ins., the centre of the turned-down portion being drilled and tapped to take a I-in, setscrew about 24 ins. long. One of these plates is placed at the end of each spring in lieu of the existing clamping plate and the setscrew tightened against the butt end of the spring, being locked with the nut when the correct chain tension is obtained, after which the four clamping bolts should be tightened. The device thus serves the two purposes of a chain adjuster and a stop to prevent axle slip.

679.—Preventing the Blowing-off of Foden Valves.

A simple but useful tip in connection with the steam valves operating the water lift and injector on the Foden steam wagon is to remove each cage and to scrape it and the seat perfectly clean, a copper and

c42 asbestos ring, as used for the sparking plugs on a petrol engine, can then be put into the cage, and the lastnamed screwed tighily home. It will then be found that this will obviate further trouble.

680.—Improving Steam Wagon Lubrication in Cold Weather.

As the result of excessive cold, the oil in a mechanical lubricator is liable to become so thick at times that many pumps fail to deliver the proper amount to the cylinders, and it is hardly necessary to emphasize the serious consequences which may occur if an inadequate supply of oil be provided. The trouble may easily be overcome by providing some easy means for warming the oil in the lubricator, and this can be done in a simple manner on the Foden wagon.

Most oil pumps are made with a small raised projection on the bottom of the pump, and a hole can be drilled from the side horizontally into this projection, and another from the bottom, vertically, to break through Into the first hole, thus affording a clear passage. At the end of each orifice suitable unions can be fitted, and

these should carry small copper pipes about in. diameter. The pipe leading from the horizontal bole is carried round and fastened by means of a small union to a steam tap fixed in the steam pipe which carries the blower jet valve. The second pipe, leading from the bottom hole, should be about 18 ins, long, and will merely form an exit for the steam.

;Cow, when the oil requirts warming, all that it is required to do is to turn on The small steam tap, when live steam passes through the first pipe and thence out from the end of the second pipe and into the air.

It is advisable to turn on the steam when about 150 lb. pressure has been reached and to keep it blowing through the pump for about five minutes. This will warm the oil thoroughly and it will be ready when steam is fully, raised. Afterwards the heat from the boiler will keep the oil sufficiently warm.