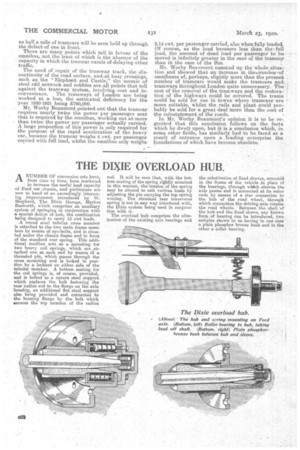

THE DIXIE OVERLOAD HUB.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

ANITMBER OF conversion sets have, from time to time, been marketed to increase the useful load capacity of Ford car chassis, and particulars are now to hand of an exceedingly interesting improvement introduced by W. Shepherd, The Dixie Garage, Market Bosworth, which comprises an auxiliary system of springing in conjunction with a special design of hub, the combination being designed to carry 15 cwt loads. A round steel tubular cross member is attached to the two main frame members by means of eye-bolts, and is situated under the chassis frame and in front of the standard rear spring. This additional merriber acts as a mounting for two heavy coil springs, which are attached one at each end by means of a threaded pin, which passes through the cross mounting and is locked in position by a locknut on either side of the tubular member. A bottom seating for the coil springs is, of course, provided, and is bolted to a square steel support which replaces the bolt fastening the rear radius rod to the flange on the axle • " housing, an additional fiat steel support also being provided and connecteci to the 'housing flange by the bolt which secures the tap member of the radius

rod. It will be seen that, with the bottom seating of the spring rigidly attached in this manner, the tension of the spring may be altered to suit various loads by adjusting the pin carrying the top spring seating. The standard rear transverse spring is not in any way interfered with, the Dixie system being used in conjunction with it.

The overload hub comprises the elimination of the existing axle bearings and

the substitution of fixed sleeves, mounted in the frame of the vehicle n place of the bearings, through wIrith sleeves the axle passes and is connected at its outer ends by means of a star connection to the hub of the road -wheel, through which connection the driving axle rotates the road wheels. Between the .shell of the hub and the fixed sleeve, any known form of bearing can be introduced, two saMples shown to us having in one -case a plain phosphor bronze bush and in the other a roller bearing.