Pressed-steel Frame for Utility Van

Page 117

If you've noticed an error in this article please click here to report it so we can fix it.

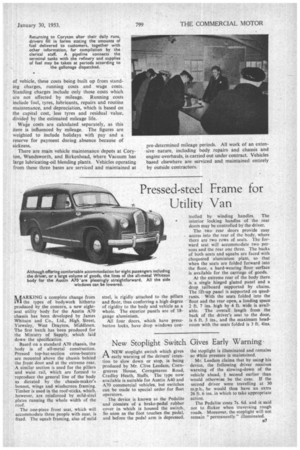

AARK1NG a complete change from 01 the types of bodywork hitherto produced by the concern, a new eightseat utility body for the Austin A70 chassis has been developed by lames Whitson and Co., Ltd., High Street, Yiewsley, West Drayton, Middlesex. The first batch has been produced for the Ministry of Supply, which laid down the specification.

Based on a standard A70 chassis, the body is of all-metal construction. Pressed top-hat-section cross-bearers are mounted above the chassis behind the front door and at the extreme rear. A similar section is used for the pillars and waist rail, which are formed to reproduce the general line of the body as dictated by the chassis-maker's bonnet, wings and windscreen framing. Timber is used in the roof-sticks, which,however, are reinforced by mild-steel plates running the whole width of the roof.

The one-piece front seat, which will accommodate three people with ease, is fixed. The squab framing, also of mild steel, is rigidly attached to the pillars and floor, thus conferring a high degree of rigidity to the body and vehicle as a whole. The exterior panels are of 18gauge aluminium.

All four doors, which have pressbutton locks, have drop windows con trolled by winding handles. The interior locking handles of the rear doors may be controlled by the driver.

The two rear doors provide easy access into the rear of the body, where there are two rows of seats. The forward seat will accommodate two persons and the rear one three. The backs of both seats and squabs are faced with chequered aluminium plate, so that when the seats are folded forward into the floor, a hard-wearing floor surface is available for the carriage of goods.

At the extreme rear of the body there is a single hinged glazed panel and a drop , tailboard supported by chains. The lift-up panel is supported on quadrants. With the seats folded into the floor and the rear open, a loading space 2 ft. 7 ins, high by 4 ft. wide is available. The overall length from the back of the driver's seat to the door, is 6 ft. 3 ins., and the maximum headroom with the seats folded is 3 ft. 4ins.