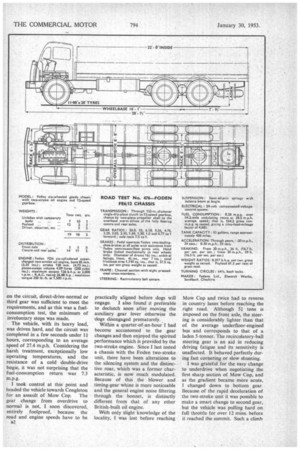

A GEAR T SPARE ON 1 1N3.8

Page 110

Page 111

Page 112

Page 113

If you've noticed an error in this article please click here to report it so we can fix it.

Fog a fraction of a second, i -WOndered what would happen next when the Foden 1 was driving, weighing almost 20 tons with full load, came abruptly to a stop with a stalled engine on Mow Cop. I was testing the overseas version of the six-wheeled chassis on the 1-in-3.8 ' gradient in Cheshire add, when making stop-start trials, I. stilled the

engine. -, In a vehicle which relies solely_ on an engine-driven pump for brake boosting this could have been serious, but when I depressed the clutch and brake pedals the starter came into action and the engine idled to give the requisite hydraulic brake pressure. Previously it ;tad made a clean climb using second gear.

This was one of the highlights in a test of a chassis equipped with the twostroke oil engine and 12-speed gearbox, which is now being shipped to South Africa for demonstration in various parts of that country. For operation in warmer climates, it was fitted with semi-tropicaltype water and oil radiators, which were blanked off over two-thirds of their frontal area, during the latter part of my trials, to maintain a moderate working temperature.

Supercharged .

The Foden standard six-cylindered 4.1-litre supercharged oil engine, which is fitted, is set to develop 126 b.h.p. at 2,000 r.p.m. and 350 ft.lb. torque at sea level. The corresponding output at 5,000 ft. is 115 b.h.p. Features of this unit include a light-alloy crankcase and cylinder-block casting with wet liners and a seven-bearing crankshaft having steel-backed white-metallined shells.

Cast-iron pistons are used and the C.A.V. N-type hydraulically governed fuel-injection pump is mounted on the Roots-pattern blower. The engine employs the Kadenacy principle of induction, in which the low-pressure supercharger delivers air to an internal chest, _where it is passed into the cylinders through tangential ports to promote swirl.

The engine is supported, together with the clutch and gearbox, on three Silentbloc mountings and draws a

cold-air supply through a large wet filter pack attached to the rear of a front panel of the cab, The main section of the gearbox has four widely spaced ratios of 6.18, 3.03, 1.69 and 1 to 1, housed in a standard cast-iron case, which is machined on the rear face to accept the preselec tive epicyclic unit. This auxiliary section has large planetary carriers, equal in torque capacity to a 5-in. gear wheel, thus overcoming the main weakness normally associated with underdrive gears.

The compound epicyclic train, which is engaged through springloaded dogs, is arranged for underdrive, normal and overdrive gears with ratios of 3.29. 1.00 and 0.77 to

1. Becanse of this spacing, the higher six gears are obtained using normal and overdrive in conjunction with second, third and top of the normal gearbox.

The transmission is taken through a two-piece shaft, supported at the

centre by a rubber-encased bearing, to a double-drive bogie, with overhead-worm gear of 81-in. centres. This bogie is an exceptionally heavy-duty unit, designed for hard work, having fully floating 2-in.-diameter .drive shafts and large-diameter integral flange driVe at the hub ends. Unlike most overseas multi-wheelers, the Foden is specified with a balance-beam linkage for the bogie suspension.

The bogie is supported on six brackets with four heavy leaf springs and compensa ting arms. To offset the load and rotary movement, large fully floating pins are , used and, sealed against dirt or water, they also embody a reservoir for grease.

Although the chassis has the Foden hydraulic-boost braking system, a Clayton Dewandre combined compressor-exhauster unit fitted, together with reservoirs for either. type of

trailer brake gear. This unit is mounted to accept a drive from the side of the gearbox, and setting for pressure or vacuum operation is controlled by a valve in the cab.

Emergency Warning

The vehicle hydraulic boost is supplied from an engine-driven

pump, but as no reservoir is included, there would be no assistance with a stalled engine. An emergency brake boost and engine-oil pressure warning device has been incorporated as a safeguard.

Should the engine stop, or the lubricating-oil pressure fall below a predetermined level, a pressure switch becomes closed to complete an electrical circuit, which sounds a warning buzzer in the cab. Immedi ately the brake pedal is pressed it connects a booster-box switch which, in turn, operates the starter motor through a relay, so rotating the engine and the brake boost pump.

Even should the engine fail to start, sufficient working pressure is available from the speed of the starter turning the flywheel. Loss of engine-oil pressure, while the vehicle is in motion, will again cause the buzzer to operate and give warning before any material damage is done.

A 22-ft.-long platform body was attached to the chassis for my tests, and with the standard all-metal cab, spare wheel, 50 gallons of fuel and all accessories, the Foden weighed 71 tons. A 12-ton payload was imposed, and after fitting the brake-marking device and other equipment, it was ready for the road.

My test was started in Sandbach, and, as a preliminary, a fuel-consumption trial was carried out from cold on a raw morning, when the temperature was 38 degrees F. When the control-panel switch was pressed down, the buzzer sprang into life and emitted a piercing noise until the starter button was pressed, and the engine fired.

Easy Starting

The engine started almost immediately the button was depressed, and after the preliminaries of weighing, loading and topping-up the fuel tank, the Foden was headed towards Middlewich on a 34.2-mile hilly circuit incorporating Northwich, Mere, Knutsford and Holmes Chapel.

On such a cold morning there was considerable oil drag, and it took practically the complete circuit to raise the transmission lubricants to anything like a working temperature. During the earlier part of the day the radiators were not blanked off, and the engine oil and water temperatures ranged from 105 to 115 degrees F.

The undulating course, with relatively short gradients, presented no obstacles to the Foden without a trailer, therefore few gear changes were required. Starting from rest in low-gear-normal, subsequent changes were made through the main gearbox, using top-overdrive as a fifth gear. When climbing normal inclines on the circuit, direct-drive-normal or third gear was sufficient to meet the requirements, arid as this was a fuelconsumption test, the minimum of involuntary stops was made.

The vehicle, with its heavy load, was driven hard, and the circuit was completed in a few seconds under 11 hours, corresponding to an average speed of 27.4 m.p.h. Considering the harsh treatment, exceptionally low operating temperatures, and the resistance of a cold double-drive bogie, it was not surprising that the fuel-consumption return was 7.3 m.p.g.

I took control at this point and headed the vehicle towards Congleton for an assault of Mow Cop. The gear change from overdrive to normal is not, I soon discovered, entirely foolproof, because the road and engine speeds have to be 132 practically aligned before dogs will engage. I also found it preferable to declutch soon after moving the auxiliary gear lever otherwise the dogs disengaged prematurely.

Within a quarter-of-an-hour I had become accustomed to the gear changes and then enjoyed the spirited performance which is provided by the two-stroke engine. Since I last tested a chassis with the Foden two-stroke unit, there have been alterations to the silencing system and the distinctive roar, which was a former characteristic, is now much modulated. Because of this the blower and timing-gear whine is more noticeable and the general engine noise filtering through the bonnet, is distinctly different from that of any other British-built oil engine.

With only slight knowledge of the locality, I was lost before reaching Mow Cop and twice had to reverse in country lanes before reaching the right road. Although 51 tons is imposed on the front axle, the steering is considerably lighter, than that of the average underfloor-engined bus and corresponds to that of a laden 5-tonner. The recirculatory-ball steering gear is an aid in reducing driving fatigue and its sensitivity is unaffected. It behaved perfectly during fast cornering or slow shunting.

I was grateful for the easy change to underdrive when negotiating the first sharp section of Mow Cop, and as the gradient became more acute, I changed down to bottom gear. Because of the rapid deceleration of the two-stroke unit it was possible to make a smart change to second gear, but the vehicle was pulling hard on full throttle for over 12 mins. before it reached the summit. Such a climb could have caused high operating temperatures, but the maximum recorded were 125 degrees F. for the top water pipe and 135 degrees F. for the engine lubricant.

I had no hesitation in reversing the lorry to the Railway Inn, where the gradient is 1 in 3.8, for stop-start tests, where by mischance I stalled the engine. My immediate actions and automatic starting of the engine have already been mentioned, but praise is due to the efficiency of the hand brake, which was used while I hurriedly engaged the lowest gear. The Foden hand brake is operated by an eccentric sprocket and chain gear which provides rapid take-up of slack and increased power when the shoes meet the drums on the bogie.

If I had been more accustomed to the vehicle it is possible that it could have been started on Mow Cop in second gear, for there was ample power when low gear was employed. Undoubtedly, the Foden is well equipped for good performance on hills, but for the best results it is essential that the engine speed should be kept within the maximum torque range.

With knowledge of the Foden braking system, I had no fears in descending Mow Cop at fair speed, using the brakes to check the pace. There was no evidence of fade and on a level stretch near the bottom of the hill it was stopped in 26 ft. from 20 m.p.h. and in 60 ft. from 30 m.p.h. The drums are finned to promote cooling, and the results of the brake tests show a retardation above average for this class of vehicle.

The characteristics of the twostroke engine do not encourage accelerating from 10-30 m.p.h. in direct drive, and with the ratios available it is unlikely that any driver would resort to using a gear which is not conducive to good performance. My tests were, there fore, confined to acceleration from rest, and, using the gearbox as a five-speed unit, 20 m.p.h. was reached in 24 secs. and 30 m.p.h. in 55 secs.

At this stage a blind was fitted to cover two-thirds of the frontal area of the radiators and a second fuelconsumption test made over the same course as chosen for the first test. The Foden was again driven hard, although more delays were incurred because of heavy local traffic. Working temperatures were raised with the top water pipe reaching 160 degrees F. and the engine

oil 145 degrees F. By mid-afternoon when this test was made the ambient reading was 42 degrees F.

Despite the delays, the circuit was completed in less time, corresponding to 28.5 m.p.h. average speed, and warmer operation, coupled with reduced oil drag in the transmission, raised the efficiency to give a fuel return of just over 8} m.p.g.