LUBRICATION AND LONG LIFE.

Page 12

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

A Lesson on Keeping the Daimler on the Top of Its Form.

IWONDER HOW MANY DRIVERS, on opening their first drivers' handbook, have been. appalled, and in ninny cases disheartened, by the enormous amount of attention which their chassis apparently needs. I myself have just picked up such a handbook. It happens to be that of the Daimler three-ton -Y-type chassis, and, although my capacity for absorbing the contents of a printed page at speed is probably rather more than average, yet even I am struck by this same thought.

This impression, that the work attached to the care of a commercial vehicle is considerable, is heightened by the seeming necessary inclusion in such handbooks of a complicated-looking chart on which all the points that call for lubrication at various times are indicated.

Now, as a matter of fact, the amount of daily attention which a modern well-designed chassis requires is p rac tically negligible. It can be accomplished by the driver , in the time necessary to walk slowly round the chassis twice, and I propose to prove this by accompanying the driver in spirit to the garage in the morning, and performing with him all that is necessary in the way of such attention before he starts out.

As the morning is cold, and in view of the very poor quality. of the war spirit which we are still receiving, we shhll probably be well advised, first of all, to start up the engine and to set the throttle in the ticking-over position, so that it will be warming up during what time we have our little talk. After starting up, the bonnet, which has presumably been lifted up for the purpose of a little carburetter flooding, or some similar operation, may be left open, and we will commence operations by lifting up that portion of the floorboard which,gives access to the lubricators on the clutch. It is better to do that part of our task which is cleanest first, and I am presuming that the driver has a good supply of engine oil, a tundish which will serve to guide that oil to the orifice through which the crank chamber is replenished, and aneoilcan.

The first operation is to attend to the engine. A turn each to a couple of wing nuts, and the cover of the crank chamber oil filler which is situated rather low down on the near side of the engine and towards the rear of that unit, is removed. Oil is poured in until it is on the point of running out again. The cover is then replaced.

Now pick up the oilcan and walk towards the rear of the chassis, keeping on the near side. We can just reach the clutch-stop joints from this side through the aperture made by lifting the floorboard. Put a few drops of oil here and also on the clutch-withdrawal pins. Further back and in front of the gearbox are another couple of clutch stop joints, and to get at these we must stoop and reach under the main chassis member. Further back again, inside the rear spring and close to its front end, are another couple of Tin joints on the brake gear. Walk right round the rear of the chassis to the off side. Put a little oil on the brake-rod pins in the corresponding position by the off-side rear spring, and further forward, at the front end of the same brake-rod joints, another application is needed, and again at the point where these rods. couple to the brake pedal.

Lay one hand on the clutch pedal, and withdraw the clutch, taking care that the small oil hole seen in the central member of the clutch is uppermost. This lubricates the thrust bearing inside the clutch, and must receive its quota of oil. We are now. at the engine again and here we require a few drops of oil on the fanshlft bearing, and passing round to the front, just below the radiator, a little should be applied to the thrust collar of the governor. • The oilcan may now be put away.

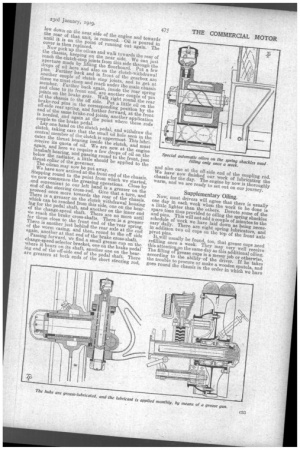

We have now arrived at the front end of the chassis. Stepping round to the point from which we started, we now commence the greasing operations. Close by and convenient to our left hand is a greaser on the end of the steering cross-rod. Give that a. turn, and proceed once more towards the rear of the chassis. There is a greaser on the clutch withdrawal housing which can be reached from this side, one on the bearing for the pedal shaft, andanother on the inner end of the change.speed shaft. There are no more until we reach the brake cross-shafts. There is a greaser for these close to the front end of the rear spring. There is another just behind-the rear axle at the end of the worm casing, and then, round to the off side again, another at that end of the brake cross-shaft.

Passing forward, we find a small grease cup on the change-speed selector bracket, one on the brake pedal where it bears on its shaft, another one on the bearing end of the off-side end of the pedal shaft. There are greasers at both ends of the short steering rod,

and also one at the off-side end of the coupling rod. We have now finished our work of lubricating the chassis for the day. The engine by now is thoroughly warm, and we are ready to set out on our journey.

Supplementary Oiling.

Now, most drivers will agree that there is usually one day in each week when the work to be done is a little lighter than the others. Devote some of the spare time thus provided to oiling the spring shackles and pins. This will not add a couple of minutes to the schedule of work we have laid down as being necessary daily. There are eight spring lubricators, and in addition two oil cups on the top of the front axle pivot pins. It.will usually be found, too, that grease cups need refilling once a week. They may very well receive this attention the same day as this additional oiling. The filling of—grease cups is a messy job or otherwise, according to the ability-of the driver. If he takes the trouble to procure or make a wooden spatula, and goes round the chassis in the order in which we have

greased up, he will find that there is very little w'ork attached to this job. Every full moon, grease is required for the steering box, cardan shaft couplings— unless these happen to be of the leather Or flexible disc type—the wheel hubs, and the volute springs, which bear upon the centre of the main rear springs. Every even month of the year, that is to say, every second, fourth, sixth, etc., the driver should remem ber to empty the used oil from the engine case, gearbox, and rear axle ; swill all three out and replenish with fresh oil. This is the only part of the lubrication of the chassis which calls for any great expenditure of time on any one occasion, There is very little more for the driver to do in connection with his chassis other than to keep it well lubricated. The brakes wear, it is true. Their adjustment on the Daimler chassis is by means of a couple of turn buckles which will be found just below and inside the frame, forward of the front end of the off-side rear spring. They are very accessible, and the work of setting up the brakes at this point is es matter of minutes.

One other point: If the universalejoints between the clutch and gearbox, or between the gearbox and rear axle, are of leather, they need a dose of castor oil once a week, at the same time as the oil-cups on the spring pins are replenished, and the grease cups filled.

As regards more ambitious adjustments and repairs, it is generally advisable for these to be undertaken by skilled repairers, It was the writer's pleasure some time ago to have described to him the plans which the ,Daimler Co. then had in mind for the establishment of service depots and agents. These were most thorough, and he formed the opinion then, as regards the Daimler, and later on as regards other firms of repute, that, whatever might have been the position in the past, it was pretty obvious that in future the user of commercial vehicles was going to be more and more attracted to the agent as an intermediary between hiniself and the maker.

The maker is providing the agent with every facility for stocking spares, and for learning all there is to be known about the chassis, and is to help the a,gent in every way to provide efficient service in connection with the vehicles which are running in his locality. The agent, for his part, will employ a staff of skilled workmen, and he will specialize on rapid periodic overhauls of his customers' chassis, besides putting in hand arrangements for emergency quick repairs in the event of occasional accidents.

Finally, one word with particular reference to the Daimler chassis and its lubrication. The valve gear of the Daimler engine is, as most of our readers are aware, of a special type. The familiar poppet valves do not obtain in this construction, the gases being admitted and exhausted through slots in the cylinder walls, which slots are covered and uncovered at the proper periods by means of sliding sleeves. It is essential that these sleeves be well lubricated, and it is advisable that a lubricant which has been selected by the makers as being particularly suitable for use in connection with their engines be used invariably. Here, again, the agent will be able to help, and the user will be well advised to take the fullest advantage of the facilities which he provides.

THE SKOTCH.