The World's Leading Tire Factories.—No. 1.

Page 3

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

The Continental Company's Works at Hanover.

The solid-indiarubber tire plays a prominent part in the economy of so many commercial motors that a few articles descriptive of works and methods of manufacture cannot fail to be acceptable to a large number of our readers. The limitations of the pneumatic tire are well known, but the solid variety has been steadily improved to the point at which its makers can make a reasonable profit at contract rates below 2d. per mile for all four wheels of a standard motorbus in London. Less than four years ago, we do not hesitate to affirm, the actual expenditure upon any such set of six tires, the back wheels, of course, having twin tires upon them, would have been in excess of 4d. per mile, arid this one fact is striking testimony to the improvements that have been effected. We take the view that the solid-indiarubber tire is surely tending to triumph over metal tires, and that there will be a still further invasion of the field which has hitherto been almost exclusively covered by steel in the treads of wheels for axle-weights in excess of six tons. One of the most valuable characteristics of rubber, its quality of deadening noise, has already brought about its adoption upon the wheels of a small number of heavy lorries in this country, whilst another of its peculiar advantages, the provision of the necessary adhesion upon snow or ice, has led to its wide adoption in countries, such as Southern 'Germany, where snow-covered roads are the rule and not the exception. The enormous extent of this industry will be largely appreciated from our following description of the first works with which we deal, those of the Continental Caoutchouc and Guita Pereha Company, at Hanover. The works in question were visited recently by a representative of " THE COMMERCIAL MOTOR," and a general view of the buildings is given at the foot of this page. Entering the town of Hanover by train from Flushing, the huge works lie to the left of the main line, and the elevated, water tanks which surround three of the smoke stacks cannot fail to attract the eye of the passer-by. The productions of this factory are known all over the world. Motorists, cyclists, athletes, and scientists alike, make extended use of the large variety of articles which are manufactured there in very considerable quantities.

The company, which is the parent of the Continental Tyre and Rubber Company (Great Britain,) Limited, of Clerkenwell Road, London, E.C., was founded in 1872, with about So workmen and with but little machinery. Since that time, it has steadily increased, in size and Importance, until, at the present time, the works cover about acres and give employment to 5,700 workpeople. These works are entirely occupied in producing soft-rubber goods, such as tires, water hose, packing rings, and the like, but the company has other works for the manufacture of hard rubber, or vulcanite, articles at Seelze, which is the first station from Hanover on the line leading to Bremen. The equipment of the Hanover factory is most complete in every way, and includes : a smithy; an engineering shop; and a carpenter's shop. These are provided in order that any necessary repairs or alterations to the plant, or to the buildings, may be expeditiously carried out. As a specialprecaution against fire, every room in the factory is fitted with an electric fire alarm, which, should a fire break out, will instantly give the alarm to each of the company's three fire stations ; in each of these, there are always on duty a sufficient number of trained firemen.

The water which is required for various purposes in the works is lifted by three powerful pumps from the company's own wells, and a very large reserve of water is always at hand in the three elevated, water tanks to which we have already referred; two of these are capable of holding 15,400 gallons each, whilst the third one has a capacity of 33,000 gallons, making, in all, 63,800 gallons of water under pressure due to a head of about too feet. Some idea of the enormous quantity of water used in the works may be gathered from the fact that over 272,000,000 gallons were used during the past year. The power house and its equipment, is quite imposing : there are two large, tandem-compound, horizontal engines of r,000h.p. each, and four smaller ones of 25oh.p. each. The running of these engines leaves nothing to be desired, there is an entire absence of vibration or noise, and the clean and smart condition of the engine rooms was most noticeable. The engines are supplied with steam from a large battery of tubular boilers, which also supply steam to the numerous vulcanisers. At the time of our representative's visit, a new battery of 6 tubular boilers, bringing the total up to thirty boilers, was just being installed. These six boilers will be mechanically fired, whilst all the others are stoked by hand. The furnaces of the boilers which were in use last year consumed no less than 42,000 tons of coal.

From the engine house, the power is transmitted to the heavy rolling mills by very stout, rope-driven shafting, which is enclosed in troughs below the floor level. To the lighter machinery in the more distant parts of the buildings, electrictransmission of power is employed. The machinery which is driven by the latter method is grouped in classes, each of which is driven by a separate motor. Altogether, over 650 machines are kept constantly at work on the various processes, including washing, mixing and masticating, through which the raw rubber must pass before it enters the stores in the form of manufactured articles.

Heavy, manual labour is avoided as far as possible, and, with that object in view, 19 electric lifts are fitted in the various blocks of buildings.

A double system of lighting is fitted throughout the works. The electric lighting installation is large enough for a small town of 30,000 or 40,000 inhabitants ; there are no less than 1,700 incandescent lamps of /6 c.p. each; 280 large arc lamps, and zo smaller arc lamps. In addition to this huge installation, gas is also provided as an auxiliary

method of lighting, or for use in case of temporary failure of the electric light. The total yearly consumption of gas amounts to 34,000,000 cubic feet. To meet the requirements of the large variety of articles which are made by the company, 75 vulcanisers are employed; the largest of these is 115 feet long and S feet in diameter.

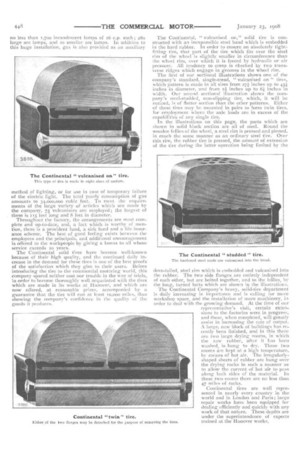

Throughout the factory, the arrangements are most complete and up-to-date, and, a fact which is worthy of mention, there is a provident fund, a sick fund and a life insurance scheme. The best of good feeling exists between the employees and the principals, and additional enCOUragernellL is offered to the workpeople by giving a bonus to all whose service exceeds to years. The Continental solid tires have become well-known because of their high quality, and the continued daily increase in the demand for these tires is one of the best proofs of the satisfaction which they give to their users. Before introducing the tire to the commercial motoring world, this company spared neither cost nor trouble in the way of trials, in order to become thoroughly well acquainted with the tires which are made in its works at Hanover, and which arc now offered, at reasonable prices, accompanied by a guarantee that the tire will run at least 10,000 miles, thus showing the company's confidence in the quality of the goods it produces. The Continental, " vulcanised on," solid tire is constructed with an inexpansible steel band which is embedded in the hard rubber. In order to ensure an absolutely tightfitting tire, that part of the tire which fits over the steel rim of the wheel is slightly smaller in circumference than die wheel rim, over which it is forced by hydraulic or air pressure. All tendency to creep is checked by two transverse ridges which engage in grooves in the wheel rim.

The first of our sectional illustrations shows one of the company's standard, single-tread, " vulcanised on " tires, which pattern is made in all sizes from 27 inches up to 451l, inches in diameter, and from za inches up to 6 inches in width. Our second_ sectional illustration shows the company's steel-studded, non-slipping tire, which, it will he noticed, is of flatter section than the other patterns. Either of these tires tray be mounted in pairs to form twin tires, for employment where the axle loads are in excess of the capabilities of any single tire.

In the illustrations on this page, the parts which are shown in solid black section are all of steel. Round the wooden tellies of the wheel, a steel rim is pressed and pinned, in much the same manner as an ordinary steel tire. Over this rim, the rubber tire is pressed, the amount of extension of the tire during the latter operation being limited by the

dove-tailed, steel rim which is embedded and vulcanised into the rubber. The two side flanges are entirely independent of each other, but are betted together, and to the fellies, by the long, turned bolts which are shown in the illustrations.

The Continental Company's heavy, solid-tire department is daily increasing in importance and is calling for more workshop space, and the installation of more machinery, in order to deal with the growing demand. At the tim.e of our representative's visit, certain extensions to the factories were in progress, and these, when completed, will greatly assist in increasing the rate of output. A large, new block of buildings has recently been finished, and in this there are two large drying rooms, in which the raw rubber, after it has been washed, is hung to dry. These two rooms are kept at a high temperature, by means of hot air. The irregularly

shaped sheets of rubber are hung over the drying racks in such a manner as to allow the current of hot air to pass along both sides of the material. In these two rooms there are no less than 47 miles of racks.

Continental tires are well represented in nearly every country in the world and in London and Paris; large repair works have been equipped fee dealing efficiently and quickly with any work of that nature. These depots are under the superintendence of experts trained at the Hanover works.