An Easily antatned Local Delivery Unit

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

By L. J. COTTON, M.I.R.T.E.

IT does not require a skilled electrician to maintain the Graiseley C1.60 pedestrian-controlled battery-electric truck, because there is only one pair Of contacts in the electrical equipment to need occasional cleaning or replacement. This task would fall within the scope of the average garage mechanic, and as the transmission comprises a simple automatic centrifugal clutch, reduction gearbox and chain drive, maintenance and repairs may be regarded as work for semi-skilled labour.

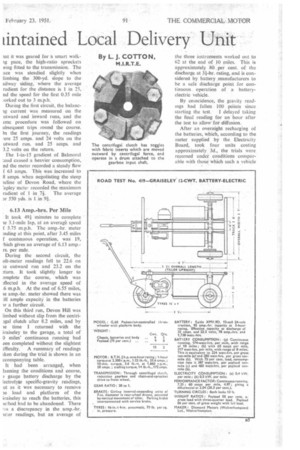

The Graiseley is a three-wheeler with front-wheel drive, the motor and accompanying transmission being carried on a platform over the front fork and moving with a swing of the tiller. A B.T.H. 2 h.p. motor and reduction box are used, the commutator shaft carrying the toggles of the centrifugal clutch. A four-toggle clutch was fitted to the test model, but a five-toggle unit is available for heavier duty.

The clutch ring is connected by its shaft to a spur and helical gear train, giving a reduction in speed of 8 to 1. From the output shaft of the gearbox the drive is taken through a chain and sprockets, the size of the sprockets being varied to suit operational requirements.

The overall reduction between the motor and wheel of the test vehicle was 28 to 1. This chain-and-sprocket drive is one of the variables in the B4 Graiseley, which can be altered to suit the pace of the roundsman, or change its range and hill-climbing characteristics Should any defect occur in the transmission it can be repaired cheaply and quickly, and there is no need to withdraw the vehicle from service It would probably take less than an hour to change the friction units of the clutch, the replacement fabric for which costs is. 4d. for a set of four. To fit a new chain, price 18s. 6d., should take less than half an hour.

The chassis frame comprises twin tubular backbone members, with the single wheel pivoted centrally at the front and carrying diagonal bracings at the rear to support the rear wheels. The possibility of wheel spin when starting away from rest on a gradient in bad weather is avoided by arranging the front-wheel position so that a high proportion of the load is carried by it. This type of vehicle does not employ any form of spring or torsion-bar suspension, but depends on small semi pneumatic tyred wheels to smooth out minor irregularities of road surface.

This was the first pedestriancontrolled battery-electric to be tested over the standard 3.1-mile course at Watford, which has been planned jointly by "The Commercial Motor" and the Electric Vehicle Association. Following a 'check of unladen and laden weights, the batteries were recharged in readiness for the continuous-running test.

Three amp.-hr. meters, an ammeter and a volt-meter were connected into the circuit for the trials, and the gravity of the electrolyte and its temperature were recorded before leaving the Eastern Electricity Board's garage in St. Johns Road, Watford.

Leading the Graiseley away from the starting point, I soon realized

lat it was geared for a smart walkig pace, the high-ratio sprockets eing fitted to the transmission. The ace was steadied slightly when limbing the 300-yd. slope to the ailway siding, where the average radient for the distance is 1 in 25, nd the speed for the first 0.35 mile forked out to 3 m.p.h.

During the first circuit, the baIancig current was measured on the utward and inward runs, and the ime procedure was followed on ubsequent trips round the course. hi the first journey, the readings Fere 25 amps. and 24 volts on the utward run. and 25 amps. and 3.2 volts on the return.

The 1-in-15 gradient of Balmoral Load caused a heavier consumption, nd the meter recorded a steady flow f 63 amps. This was increased to 8 amps. when negotiating the steep icline of Devon Road, where the 'apley meter recorded the maximum radient of 1 in 71. The average Jr 550 yds. is 1 in 9.

6.13 Amp.-hrs. Per Mile

It took 491 minutes to complete le 3.1-mile lap, at an average speed f 3.75 m.p.h. The amp.-hr. meter !ading at this point, after 3.45 miles f continuous operation, was 19, ,hich gives an average of 6.13 amp.rs. per mile.

During the second circuit, the olt-meter readings fell to 22.6 on le outward run and 23.2 on the !turn. It took slightly longer to Dmplete the course, which was !fleeted in the average speed of .6 m.p.h. At the end of 6.55 miles, ie amp.-hr. meter showed there was :ill ample capacity in the batteries inr a further circuit.

On this third run, Devon Hill was limbed without slip from the eentriigal clutch after 8.2 miles, and by ie time I returned with the iraiseley to the garage, •a total of D miles' continuous running had cen completed without the slightest ifficulty. A summary of readings iken during the trial is shown in an ccompanying table.

It had been arranged, when fanning the conditions and course, ) gauge battery discharge by the Lectrolyte specific-gravity readings, ut as it was necessary to remove le load and platform of the lraiseley to reach the batteries, this iethod had to be abandoned. There as a discrepancy in the amp.-hr. ie:er readings, but an average of

the three instruments worked out to 62 at the end of 10 miles. This is approximately 80 per cent. of the discharge at 34-hr. rating, and is considered by battery manufacturers to be a safe discharge point for continuous operation of a batteryelectric vehicle.

By coincidence, the gravity readings had fallen 100 points since starting the test. • I delayed taking the final reading for an 'hour after the test to allow for diffusion.

After an overnight recharging of the batteries, which, according to the meter supplied by the Electricity Board, took four units costing approximately 3d., the trials were resumed under conditions comparable with those which such a vehicle would encounter in service. The first mile was made without stop, after which there were 60 halts to every mile.

The same course was followed for the "stopping" run, and the difficult part of Devon Road was climbed at mileotneter readings of 20, 5.1 and 8.2 after leaving the garage.

The Graiseley showed no reluctance to move away from rest on the 1-in-7i incline during the first lap, but there was a noticeable clutch slip at the same point during the second circuit. For such hilly work, or worse, the maker would fit lowerratio sprockets and a five-toggle clutch.

Towards the end of the seventh mile the voltage drop began to increase, and at 8.2 miles the vehicle came to its first halt, with clutch slip. on Devon Road. The centrifugal clutch is a safeguard against overload on the motor, and dispenses with the conventional fuse.

At this juncture the test was concluded, because the 80-per-cent. safedischarge point of the battery was reached. The vehicle still had to be returned to the garage almost two miles away, and with care it was coaxed to the brow of Devon Road, and completed the third lap with assistance on the steeper gradients.

These tests proved that for milk delivery, the most arduous type of duty to which the battery-electric can be subjected, the Graiseley would have a normal range of 8 miles. This distance would comprise a mile run from the depot to the first delivery point, six miles with 60 halts per mile and a mile back to the depot carrying a half-payload of empty bottles.

For convenience of loading and to accommodate the instruments on the initial test, the vehicle was tried with a flat platform, but other types of body for bread, milk crates and other loads are available.