Rough experiences have taught American operator Keith Harring how to

Page 78

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

look after himself in the cut-throat world of road transport. Tint Maughan crossed the Atlantic to meet an outspoken haulier making the most of an economic boom in a colossal market.

Outside the inunaculately-kept building that • houses -• Philadelphia's 3oth Street railway station is a hive of-activity: Pontiacs rush by, office workers enjoy .a break from work in ,the sunshine and. Cls manhandle their packs on to the concourse. A quarter of a mile 'away office blocks thrust hundreds of feet towards the blue sky. This is industrial America, a cotintry enjOying unpi.ecedented levels of wealth. Washington DC lies to the south; to the north is New York and then Boston. These are thebig east coast cities, representing just , a fraction of the US. Philadelphia alone has a 'populatidn of three, millionenuiyalent to 'six:StAeldS. The scale of things is huge compared with the UK! and the haulage industry is no different We met Keith Harring, 'owner of KL Harting, Transportation, based in the small town of Bethel, deep in the .Appalaehian

Mountains. ;

Soorf . we are cruising through the Pennsylvanian Countryside in his BMW 7 series. First impressions indicate that Hatring is doing well.

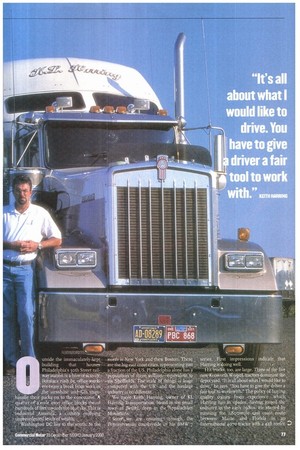

Lis trucks, too, are large. Three of the five new.Kenworth W99o1 tractors-dominate the depot yard, "It is all about what T would like to drive," be says. "You have to give the driver a fair tool to work,with," The policy of buying quality comps from experience, which Harring has in spades, having joined the industry in the early 19805. He =started by running the 1,800lnile east coast route between Maine and Florida in an International 4070 tractor with a 42ft reefer. D

P Gradual expansion followed, but in 1986, when he was operating four trucks, things began to turn sour. Harting was suffering from kidney problems. And it got worse: doctors found he had been born with just one kid. ney. Harring had experience as a driver, but it was during his illness that the complexities— and the cut-throat side of road haulage became apparent_ He says: "When I was in hospital, my trucks were subcontracted out to a Pennsylvanian haulier so I would be paid a percentage rate, but only when the vehicles were used. However, when I was sick he kept the vehicles off the road."

Hospital

Harting, recovering in hospital was powerless to get his trucks rolling. If anything, it taught him an invaluable lesson: don't give up, and get the job sorted yourself. "I took the bull by the horns. worked hard, I knew I could do what it took," he says. It may sound ironic, but the experience turned him off subcontractors and now the owner of 35 tractors dismisses them as a nuisance, "I have some emotion for them because that is where I started; but you give them a couple of dollars and then they don't want to do the job," he says.

To do that job Harring runs his own fleet It is a straightforward policy and he cuts no con ners. Investment in staff is vital; he buys the best trucks so he needs the best men to drive them. Five of the drivers are referred to by Harring as "fighter pilots"—men who give their boss the very best. He says: "My greatest resource is people. When I have this everything follows." He also ensures that his drivers get paid holidays—in the US such a policy is by no means the norm.

British hauliers will be surprised to learn that drivers are paid by the mile. "This is standard for a company of this size," says Harting. On return journeys, the driver picks up 25% of the mileage. Loading and unloading, switching trailers and so on brings a separate payment. In the US you are paid for what you do—no more, no less.

Harring's sense of purpose is clear: "My goal is to haul freight out of here and take it to its destination." That, of course, is what haulage is about. But in the US trips are long, and different drivers take different jobs. "Some guys run the West, some run a 5oo-mile radius from base, and some do local work." As well as operating in all the mainland states, KL Harring Transportation trucks also run in Canada. With distances so great, the price of fuel would be an issue for a British haulier contemplating similar journeys in Europe. But in the US diesel is a snip at 8op a gallon—four times cheaper than in the UK.

The enormity of the country is reflected in the time it takes to do a trip from, say, New York to the west coast and back to Bethel: nine days. Harring says: "Drivers can work only 7o hours total in eight days, or Go hours in seven days. Then he must take a rest."

The Federal Highways Safety Administration scrutinises drivers' hours, hauliers' safety records and vehicle maintenance; the equivalent of the British 0-licence is the Certificate of Authority. The Commercial Driving Licence is the US version of the Class I. But tachographs are not used in the US. Harring says: "Drivers must fill out a log sheet every day; they must put down all times on this, as well as fuel and delivery receipts." He adds: "Drivers also have to pass a physical test every two years. I send my drivers to a local hospital to do this."

Employing healthy, competent drivers is essential, especially when consignments are electronic goods, pharmaceuticals and expensive polished metal computer components. Such loads are Harring's speciality—many of the goods are manufactured within 12 miles of the KL Harring depot. They are often stored in the firm's 3,72omz warehouse, and are usually palletised. Then it is the job of the 35-strong tractor fleet to deliver them. Harring guarantees 24-hour delivery for trips up to L000 miles. Like many UK hauliers who have chosen to invest in warehousing, Harring's distribution accommodation is paying off. "The return on this building has been phenomenal," says Harting. He is planning to build another warehouse with a capacity of 7,000mi.

After all the overheads have been calculated, how much money is Harting taking home? He estimates that the typical American haulier enjoys a clear profit margin of about 8% per cent—but his net profit stands at a hefty 18%. How does he achieve this? Close liaison with the customer is crucial, he says. "We become their problem solver, we have to deal with the whole manufacturing process; we are an asset to the company."

Such a close relationship with the customer is important, yet ultimately Harring's faith lies with his drivers. By building a reputation for treating his staff well, Harting never needs to advertise for drivers. His face turns serious when asked about his policy towards his people: "I always stick up for my drivers, and I always make sure they are home at Christmas. If a customer says they will not give me business because my drivers are not available, that is fine." In that no-nonsense vein, Harring refuses to negotiate rates. He readily admits that his service is not always the cheapest; if the customer wants the best haulier to shift expensive consignments properly, he has to be prepared to pay for it—and inevitably he will.

Regime

He also has a strict regime in running his fleet governed by the principle of using time to maximum effect. Vehicles are protected by a three-year warranty and he sells them before the warranty expires. "My concept is that when I sell the vehicle there is still warranty left on it, which means it sells well." In short, the warranty means a protective umbrella, and an invaluable selling point.

So, there is Harring's formula. Look after your staff, tailor your business precisely to demand, invest in the right equipment and don't get pushed around by your customer. For a haulier like Keith Harring the economic boom means a wealth of work. Saying that, if a customer isn't playing ball, he'll take his trucks elsewhere: "You have got to have pride," he says.

rAcTrILE

KL Harring Transportation

BASED Bethel, Pennsylvania.

FOUNDED 1983, in Valley View, Pennsylvania.

CONTACT Keith Harring, owner.

FLEET 35 tractive units, all Kenworths.

Operates van trailers and reefers. Buys new. Most recent purchase: Batch of five Kenworth W900L tractive units, October 999.

SPECIALITY Express high-value goads transport.

TURNOVER $5m (£21m).