A New Vehicle fc 40-ton Loads

Page 40

Page 41

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

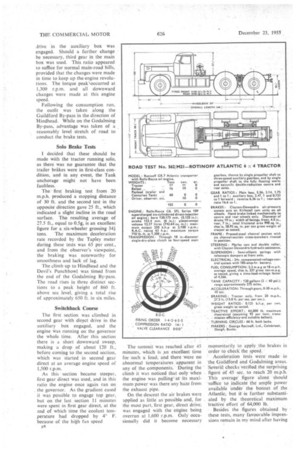

Rotinoff Atlantic Tractor with Rolls-Royce 250 b.h.p. Supercharged Oil Engine Tested: Rapid Acceleration, High Cruising Speed and Powerful Braking

DESIGNED primarily for the haulage of indivisible loads or multiple trailer trains up to A gross weight of 140 tons, the Rotinoff GR.7 Atlantic transporter is a surprising newcomer to a field of transport which, in this country, has been principally dominated by a handful of well-established vehicle manufacturers.

This is not by any means the most surprising feature of the . Atlantic, however: its performance shows it to be a severe challenger to these well-established concerns and its construction is simple enough to suggest that its selling price will be favourable.

During a hurried one-day road test of the Atlantic I was able to assess some of its qualities when hauling a gross train Weight of 103 tons. The acceleration and cruising siteed afforded by the Rolls-Royce supercharged oil engine are high, and the brakitig power is of the same standard. .

A 10-mile road run over nonetoo-favoUrable country at an average speed of 18 m.p.h-. resulted in a fuelconsumption rate of 2.3 m.p.g., whichis a -sure indication that the

Rolls-Royce • engine can be economically worked at a high rate.

Frame 12i in. Deep.

The basis of the Rotinoff tractor is a straightforward pressed-steel chassis frame. The side members are 121 in. deep and have 3i-in. flanges and, like the rest of the frame members, are pressed from thick plate.

Channel-section cross-members are used and at the centre line of the bogie the cross-member consists of two channel sections placed back to back. Gusset plates are attached to the upper flanges of the side members of the rear half of the frame. Riveting is used throughout, and a fullwidth channel-section front bumper forms part of the standard specification.

With a maximum output of 250 b.h.p. at 2.100 r.p.m., the Rolls-Royce C6 SFL supercharged six-cylindered oil engine has proved to be entirely satisfactory for the purposes for which the Atlantic was designed.

There is provision under the bonnet, however, for the -Rolls-Royce eight-eylindered unit, should this be required for exceptionally arduous conditions, and for this reason there is .a short propeller-shaft drive between the engine and the fan. The space on each side of this drive is occupied by the oil-bath air cleaners in the present design, and they would have to be mounted outside the bonnet if an eight-cylindered engine were fitted.

The engine is conventional in design •and the gear-driven Rootstype supercharger is manufactured by Sir George Godfrey and Partners (Industrial), Ltd. Its normal working pressure is 8 p.s.i. above atmospheric.

Dry-sump lubrication is employed and the oil reservoir incorporates a heat exchanger through which the engine coolant is passed from the radiator. This ensures speedy warming up of the lubricant when starting, and enables the most suitable running -temperatures to be maintained at all times.

An all-speed mechanical governor is fitted to the fuel pump and a twincylindered air-cooled 15-cu.-ft. compressor is mounted above the timing gear case on the near side of the engine. This is driven by twin V-belts from a pulley on the supercharger drive gear. A gear-type hydraulic pump, driven from the front of the crankshaft, supplies power for the steering ram. .

As the bonnet is large, there is plenty of room for fitters to work comfortably on the engine, and routine maintenance should present no difficulties. The power unit carries an 18-in, diameter clutch.

The four-speed constant-mesh, • main gearbox is mounted in unit with the engine, the complete assembly being rubber-mounted at four, points. A short propeller shaft connects the main box to the three-speed auxiliary box, and both gearboxes are of David Brown manufacture; having , been built specially to the Rotinoff specification.

At present, the auxiliary-box gear lever has to be moved through a Y-shaped path and has a long travel, but on subsequent models this is to be modified so that lever travel is fore and aft.

Kirkstall axles are used throughout the chassis. The front-axle bed is a one-piece forging of heavy rectangular section, and the stub axles are carried on tapered kingpins which run in roller bearings and bronze bushes. The standard front wheel tyres are 14.00-24 in. (12-ply).

The rear bogie is similar to that employed in another British heavy tractor, and both axles incorporate double-reduction gears. The first reduction is through worm gearing and the second reduction through epicyclic trains, which also supply the differential effect.

Axle location -is by ball-ended radius arms, which relieve the springs of all torque, braking and side stresses. The suspension is such as to allow 15 in, of articulation between diagonally opposed wheels. Standard tyres are 18.00-25 in. (16ply).

The inverted semi-elliptic rear /sprines have full trunnion mountings and each is 74 in. long and 5 in.

wide, with 15 leaves. The front semi-elliptic springs each have 16 leaves and are 48 in. long and 4 in. wide. All springs are of silicomanganese steel, and chromiumplated shackle pins are fitted z hroughout.

A 28 to 1 ratio for the Marks heavy-duty cam-and-double-roller steering gear gives 4+ turns of the wheel from lock to lock. In view of the large front tyres and the obviously high front-axle loading, it is not surprising that power assistance is used.

Clayton Dewandre constant-flow hydraulic equipment is fitted and the double-acting power cylinder operates directly on the steering gear through a relay lever interposed in the drag-link. The self-centring effect of the steering is retained under all conditions and there is no tendency to wander or over-correct at speed.

Clayton Dewandre air-pressure braking is employed. The.Kirkstall brake units at each wheel are actuated by individual power cylinders controlled by the foot reaction valve and connections are provided for two-lino trailer air brakes. A relay valve is incorporated in the system to apply the trailer brakes before those of the tractor.

As supplied for test, the Rolinoff was equipped as a motive unit for a drawbar trailer, and was carrying nearly 17 tons of ballast. The tractor can be used also for semi-trailer working, although, In this instance, it is normally necessary to replace the large single rear tyres by twins.

Twin Tyre Conversion This conversion can be carried out by changing the wheel hubs and fitting different springs, which reduce the distance between the axles of the bogie. The frame is already equipped to enable a fifth-wheel turntable coupling to be mounted in place of the ballast box. When the Atlantic was demonstrated in Europe earlier this year, all the necessary equipment for conversion was taken over, which shows that it is not a workshop job.

On the day of the test the tractor was waiting for me on the main road at Sunningdale, and its load consisted of a Dyson 50-ton 32-wheeled trailer, carrying a disabled Centurion Tank.

' A 5-gal. drum had been anchored to the front bumper and was to be used for the fuel-consumption run. This 9.9-mile run was made from Sunningdale to Worplesdon, just outside Guildford, and the route chosen was through Bagshot and Bisley. In places the course was hilly and, once off the main road, the roads became very narrow.

It -speaks well for the power and manceuvrability of the unit that an average speed of 18 m.p.h. was maintained over this course, and at the end of this distance it was found that 4.3 gal. of fuel were required to replenish the test tank.

The run was uneventful, and once we had starte21 I turned round quickly to see whether the trailer was still attached, because acceleration was so great. The engine had cooled off while waiting for the beginning of the test, but within five minutes it had assumed its normal running temperature of 168° F. This temperature was maintained throughout the day, ambient temperature varying between 45° F. and 50° F.

While on the consumption run I noted the technique of the driver in maintaining speed. On anything like 'flat surfaces it was possible to use top gear and high ratio, but on approaching a slight gradient, direct

drive in the auxiliary box was engaged. Should a further change be necessary, third gear in the main box was used. This ratio appeared to suffice for normal main-road hilts, provided that the changes were made in time to keep up the engine revolutions. The torque peak+occurred at 1,300 r.p.m. and all downward changes were made at this engine speed.

Following the consumption run. the outfit was taken along the Guildford By-pass in the direction of Hindhead. While on the Godalming By-pass, advantage was taken of a reasonably level stretch of road to conduct the brake tests.

Solo Brake Tests

I decided that these should be made with the tractor running solo, as there was no guarantee that the trailer brakes were in first-class condition, and in any event, the Tank anchorage might not have been faultless.

The first braking test from 20 m.p.h. produced a stopping distance of 30 ft. and the second test in the opposite direction gave 25 ft., which indicated a slight incline in the road surface. The resulting average of 27.5 ft., equal to 0.5g, is an excellent figure for a six-wheeler grossing 341 tons. The maximum deceleration rate recorded by the Tapley meter during these tests was 65 per cent., and from the observer's viewpoint, the braking was noteworthy for smoothness and lack of lag.

The climb up to Hindhead and the Devil's Punchbowl was timed from the end of the Godalming By-pass. The road rises in three distinct sections to a peak height of 860 ft. above sea level, giving a total rise of approximately 650 ft. in six miles.

Switchback Course

The first section was climbed in second gear with direct drive in the auxiliary box engaged, and the engine was running on the governor the whole time. After this section there is a short downward sweep, making a drop of about 120 ft., before coming to the second section, which was started in second gear direct at an average engine speed of 1,500 r.p.m.

As this 'section became steeper, first gear direct was used, and in this ratio the engine once again ran on the governor. As the gradient eased it was possible to engage top gear, but on the last section 11 minutes were spent in first gear direct, at the end of which time the coolant temperature had dropped by 4° F. because of the high fan speed The summit was reached after 45 minutes, which is an excellent time for such a. load, and there were no abnormal temperatures apparent in any of the components. During the climb it was noticed that only when the engine was pulling at Its maximum power was there any haze from the exhaust pipe.

On the descent the air brakes were applied as little as possible and, for the most part, first gear, direct drive, was engaged with the engine being overrun at 1,600 r.p.m. Only occasionally did it become necessary momentarily to apply ,the brakes in order to check the speed.

Acceleration tests were made in the Guildford and Godalming areas. Several checks verified the surprising figure of 45 sec. to reach 20 m.p.h. This average figure' alone Should suffice to ,indicate the ample power available under the bonnet of the Atlantic, but it is further substantiated by the theoretical maximum tractive effort of 64,000 lb.

Besides the figures obtained by these tests, many favourable impressions remain in my mind after having spent several hours in the cab of the vehicle. Among these should be cited the almost complete absence of vibration, the excellent suspension and the small amount of noise from the engine and the transmission. Slight blower whine was discernible, hut this was not by any means as high as might be expected. ' The three-man cab, which has lefthand drive to afford the driver a clear view of the kerb, has sliding doors, which are normally left open. Should the weather demand that these be shut, the cab quickly warms up. The general visibility is reasonably good, although the length of the bonnet tends to create the impression of driving a portable football pitch.

There was no time duringthe day's testing to carry out any maintenance tasks, but from the simple construction of the chassis it appears that there would be little trouble experienced in normal maintenance or in unit exchanges, allowing for the size of the units involved.