UPDAT FLAGS ED

Page 28

Page 29

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

IP Renault has added a second steered axle and reduced fuel consumption on its G290 38-tonner. Was the result worth the investment? CM finds out.

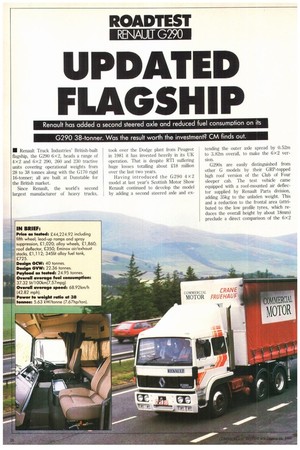

• Renault Truck Industries' British-built flagship, the G290 6x 2, heads a range of 4x2 and 6x2 290, 260 and 230 tractive units covering operational weights from 28 to 38 tonnes along with the G170 rigid 16-tonner; all are built at Dunstable for the British market.

Since Renault, the world's second largest manufacturer of heavy trucks, took over the Dodge plant from Peugeot in 1981 it has invested heavily in its UK operation. That is despite Rh I suffering huge losses totalling about £18 million over the last two years.

Having introduced the G290 4x2 model at last year's Scottish Motor Show Renault continued to develop the model by adding a second steered axle and ex

tending the outer axle spread by 0,52m to 3.82m overall, to make the 6x 2 version.

G290s are easily distinguished from other G models by their GRP-topped high roof version of the Club of Four sleeper cab. The test vehicle came equipped with a roof-mounted air deflector supplied by Renault Parts division, adding 35kg to the unladen weight. This and a reduction to the frontal area (attributed to the low profile tyres, which reduces the overall height by about 18mm) preclude a direct comparison of the 6x2

model with the 4 x 2 G290 previously tested (CM November 16, 1985).

A change in final drive ratio from 5.13 to 4.55 compensates for the smaller wheels so that the overall gearing is just 1% lower than before.

Other options add to the basic chassis price of E39,690. Some items, like the Eminox air intake and exhaust stacks, add to the vehicle's unladen weight, but others such as the alloy wheels and low profile tyres reduce it.

From the driving seat the 6x2 has several advantages over the 4x2 alternative. The longer tractive unit wheel

base gives a stable ride resistant to both pitch and roll.

• HANDLING

The front and rear axles are suspended on parabolic leaf springs with anti-roll bars, aided by the York air suspension conversion on the second steered axle.

The cab, suspended at the rear by gas struts, adds little to the chassis roll, the resulting level ride accentuating the ease of control of the twin-steered vehicle. The 6x2 configuration, by allowing use of a tandem axle trailer, also appears to contribute to a lower rolling resistance and on the level and downhill stretches the vehicle rolled along freely. In tight manoeuvres the tyres of the trailer's tandem axle are less prone to scrubbing and should give an extended life.

Our Crane Fruehauf test trailer has a uniformly-distributed load. Individual axle weights indicate that there is ample capacity in hand to cater for more concentrated loads. For this reason alone tandem axle semi-trailers are becoming more common. Crane Fruehauf say that about 25% of its production is devoted to manufacture of tandem axle trailers for general haulage.

Tipper operators are the exception, buying only one in eight tandems while no doubt hoping for an increase in the weight limit to 40 tonnes. For more than a year now three axles have been specified on 27% of all units registered for operation at 32 tonnes and above.

The more powerful the machines (such as those specified for 38 tonne operation) the stronger that trend becomes.

• FUEL ECONOMY

Over CM's Scottish Test route the 6 x 2 G290 returned a fuel consumption of 37.321it/100km (7.57mpg) — a 1.43.1it/100km (0.28mpg) improvement over our results with the 4x2 tested at comparable speeds. The reduction in fuel consumption was shown to be consistent over every section.

Seventh low is direct drive in the 16speed splitter gearbox, making each of the three higher gears overdrive ratios.

• PERFORMANCE

In top the vehicle has a geared speed of 125km/h (78mph). It pulls 97krn/h (60mph) at 1,600rpm, 80km/h (50mph) at 1,350rpm and 64km/h (40mph) at just be low maximum torque at 1,100rpm. It is worth rioting at this point that the low profile tyres have a speed rating of only 109km/h (68mph).

• TRANSMISSION

The double H-shift pattern is biased towards the soft central detent. Reverse and crawler gears are protected by a stronger spring.

Full synchromesh allows fast, slick changes without any hesitation. Even on the toughest hills full downward changes can be made with little loss of impetus although skip changes of one or one-and-ahalf ratios are needed at some points. Here the dash-mounted warning lamp proved useful, indicating the high or low split position. Stepping down a gear increases engine speed by about 200rpm so drive can be maintained at or about maximum torque in the most economical sector of the power band for most of the time, with the engine willing to pull strongly down to 1,100rpm when required.

We carried out the specific tests at the Motor Industry Research Association's test track before setting out on the road. While recording acceleration times the engine became noisy, lost power and began to produce black smoke.

With the cab tilted at 50 degrees we looked for a possible cause. Almost immediately we spotted a tell-tale blacking about the exhaust manifold but this could not have accounted for such a loss of power and increase in noise.

Further inspection revealed that the rubber pipe between turbocharger and intercooler had become dislodged at the turbocharger end. We had encountered a similar fault with the previous 4x2 where the torque clip had proved insufficient to retain the pipe at the opposite end without the benefit of a lip to swell it out and provide the extra degree of grip.

With a new set of manifold gaskets and the retaining bolts torqued down to the correct loading the exhaust leak was soon cured, while the pipe only needed to be relocated. It stayed in place and showed no signs of movement over the duration of the test but is an obvious weak point.

11 BRAKES

Dynamic brake tests showed a fault in individual axle braking distribution. At both 321(m/h (20iriph) and 48km/h (30rnph) full pedal applications caused lock-up on the drive axle while both steered axles continued to rotate. This caused the vehicle to jackknife. While the static roller brake test gives individual axle brake efficiencies it would not necessarily show this vehicle's instability. On most lesser applications the service brakes gave a smooth uneventful response but on a couple of occasions heavier braking from about 80kmili (50mph) down to 25km/li (15mph) caused a judder.

Initial attempts at hill restarts were thwarted by low air pressure. Full air pressure allowed the park brake to release quickly and the vehicle then was able to pull away cleanly on the 20% gradient.

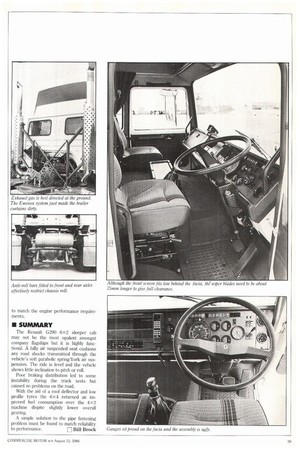

• CAB COMFORT

Inside the cab Renault has revised the curtain track so it runs above the front screen and the curtains can close off all the windows. The raised roof makes it easier for the driver to stand before climbing onto the bunk.

The instruments stand proud of an uninspired painted facia and form a rather ugly, albeit functional installation. Gauges have been arranged so that for normal readings each of their needles points in the same direction, highlighting any malfunction should they differ dramatically.

Windows are a good size providing ample vision. Door windows are unsupported along the leading edges and tend to vibrate when partially lowered. The rubber moulding protecting the lower edge of the facia became unstuck, and although not completely reliant upon glue to keep it in place it persistently fell off.

The standard glass sunroof is covered by the roof-mounted fairing but could be opened to one of three settings for ventilation.

Indicator and wash/wipe stalks sprout from the dash board on either side of the steering wheel allowing fingertip control. By contrast the heating and ventilation controls are mounted at the centre of the dash out of comfortable reach.

The G290 was fitted with a radio telephone tuned into British Telecom's Cellnet system — the first CM test vehicle to feature this equipment. A remote microphone located high at the side of the windscreen allowed hands-on operation while on the move. Reception was good for most of the test route in England but almost non-existent north of Shap.

The speaker, situated behind the driver's seat, offered good reproduction but the engine noise tended to drown transmissions.

The telescopic gear lever need not be disconnected before tilting the cab and incorporates an effective seal against the noise of the engine. The same cannot be said of the point where the steering column passes through the floor. From the driving seat, daylight is clearly visible through the hole.

The chrome Eminox stacks are tuned to match the engine performance requirements.

• SUMMARY

The Renault G290 6x2 sleeper cab may not be the most opulent amongst company flagships but it is highly functional. A fully air suspended seat cushions any road shocks transmitted through the vehicle's soft parabolic spring/York air suspension. The ride is level and the vehicle shows little inclination to pitch or roll.

Poor braking distribution led to some instability during the track tests but caused no problems on the road.

With the aid of a roof deflector and low profile tyres the 6x4 returned an improved fuel consumption over the 4 x 2 machine dispite slightly lower overall gearing.

A simple solution to the pipe fastening problem must be found to match reliability

to performance. n Bill Brock