5-Tonner Designed for Del

Page 50

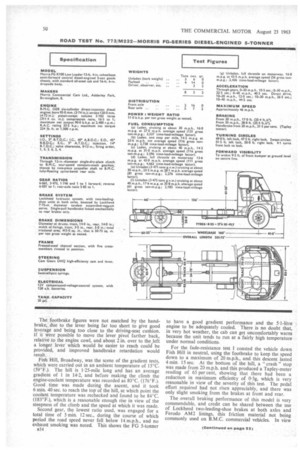

Page 51

Page 52

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

By

John F. Moon, A.M.I.R.T.

ROAD TEST: Morris FG-Series Diesel-engined 5-tonner ASIGN of the growth of the British commercialvehicle industry (in more senses than one) is that . whereas, say, 10 years ago a 3-ton chassis was regarded as about the top limit for delivery duties, nowadays more operators are turning to 5-ton vehicles for this work. Thus, the average 5-tonner of 1953 was hardly laid out to make it easy for the driver to get in and out of his cab and to provide the maximum all-round visibility for working under congested traffic conditions. But a look at the current market reveals several 5-ton designs showing consideration of delivery-service operators' needs. A furthei trend has been the use of small-diameter wheels to lower the body-loading height and give maximum manceuvrability.

A good example of this current trend is the B.M.C. FG-series 5-tonner, available either as an Austin or a Morris (according to one's choice of supplier) and which was originally introduced at the time of the Scottish Motor Show in November, 1961, but which has gone into full production only comparatively recently. As its serial letters suggest, this 5-tonner has the well-known B.M.C. FG corner-door cab, which was developed in 1959 for a range of B.M.C. 2-, 3and 4-ton chassis, the3e having been joined by a 1.5-ton model early in 1960.

When introduced, this cab design hit the headlines in.a big way, for its unconventional shape had been arrived at through the application of ergonomics by Prof. G. C. Drew,

of London University. His tests showed that the door, floor and step layout of the FG cab reduced the average energy requirement for getting in and out of a cab by nearly one-third compared with that of a conventional forward-control cab with access over the front wheel. Further tests showed that manceuvring time was greatly reduced because of the improved range of vision compared with that given by contemporary cabs, whilst various measurements showed that drivers were more relaxed at the end of a full working day when employed in an FG cab, again compared with a conventional forward-control design.

There is no doubt about the easy access of the FG cab, even when used on a 5-ton chassis: the unconventionally positioned door behind the front wheels and wide hubheight steps have positive advantages. Unlike several other makes in this payload category, also intended for delivery operations, the FG's driving seat cannot be reached from the kerb side unless the driver has the ability of a gymnast, for the engine cowl offers an almost insurmountable obstruction down the centre of the cab. iwever, because the doors, when fully opened, do not • ct beyond the body sides, it is comparatively easy for river to use the traffic side without danger of obstructiassing vehicles.

c-cylinder petrol or diesel engines are offered in the 5-tonner, and the extra length of the diesel unit pared with the four-cylinder engines employed in the er models) has necessitated the addition of a " snout " e front of the cab. This increases the front overhang ust over 7 in. and makes the 5-tanner, in effect, a -forward-control vehicle. The additional front over ; has little effect either on forward visibility or the circle.

would make one further observation on the FG cab. engine accessibility is very poor, the detachable front giving immediate access to the radiator, oil-bath air ler and part of the electrical equipment, whilst the t. removable panels of the cowl section inside the cab ttle more than enable one to look at the engine. Good ne accessibility still plays an important part in the cc of a vehicle, and it is a great pity that the FG iner falls down so badly in this respect.

nlike many current British models, the FG 5-tonner a remarkably simple specification so far as choice of native equipment is concerned. Other than the two nes already mentioned, there is offered a choice of axle ratios, the availability of suspension dampers at t and rear and a choice of tyre equipment to increase ;ross weight rating from the standard figure of 8-25 tons I tons. Apart from that, the design is offered on a ce it or leave it" basis, which is not such a bad thing tly because it helps to simplify choice and purchase.

he basic chassis assembly has much in common with r B.M.C. 5-ton models, which is an advantage for the -ator. The available engines are the B.M.C. 5.1-litre el with C.A.V. DPA distributor-type pump, this being unit fitted to the vehicle tested, whilst the alternative ie B.M.C. 4-litre o.h.v. petrol engine, with net ratings ;7 b.h.p. at 3,000 rpm. and 196 lb. ft. torque at 1,000 n. Only one wheelbase is offered (13 ft. 4 in.) so a twoe propeller shaft is standard, linking the four-speed slant-mesh gearbox with the spiral-bevel axle, the tdard ratio for which is 5.85 to 1 with the diesel engine, ons being 5-125 and 6.67 to 1. The standard ratio aid be adequate for most purposes, as it gives a gradient ity in excess of 1 in 4, a top speed of more than 45 m.p.h. and very good acceleration when running at the 8-25-ton rating, and thistenerally good performance should be adequately maintained even at 9 tons.

The FG 5-ton chassis has 0-25-in.-thick pressed side members with a maximum depth of 9.125 in. The basic suspension system is extremely simple, albeit effective, consisting of 45-in. by 2-25-in. front springs and 60-in. by 2.5-in, rear springs. Rear helpers are standard on export models but optional for the home market, although these must be fitted when the vehicle is to be operated at 9 tons gross. For the standard gross rating, 8.25-17 (10-ply) tyres are fitted; for use at 9 tons 8.25-17 (14-ply) tyres are mandatory.

Use of 17-in, wheels leaves comparatively little room for • drum brakes, but the vacuum-assisted Lockheed hydraulic system is very efficient, both in respect of colddrum "crash" stops and fade resistance. Despite its 14-in. drums, the lining area of the FG 5-ton chassis is actually 46 sq. in. greater than that of other B.M.C. 5-ton forwardand normal-control chassis with 20-in. wheels.

The FG K100 5-ton model is available as a chassis-scuttle, chassis-front end, chassis-cab, platform lorry or drop-side lorry. The vehicle I tested had the standard B.M.C.-built lorry body with angled headboard (to give clearance for the doors) and a maximum interior length of 16 ft. 6 in., the interior length at the sides being 16 ft. 1.5 in. because of the headboard shape. In kerb condition, the 5-tonner, which had the 10-ply tyres, weighed 3 tons 6 cwt. Gravel was carried to bring the gross weight up to 8 tons without passengers, 5 cwt. less than the manufacturers' recommended gross rating.

Footbrake efficiency was extremely high and the stopping distances were achieved without any wheel locking. Figures of under 40 ft. from 30 m.p.h. are rarely obtained with vehicles of more than 1-ton capacity, so it can fairly be said that this B.M.C. 5-tonner's braking performance is well above average for a vehicle of its weight.

Although the retardation was smooth, the payload proved more difficult to stop and, as a result, during each deceleration test the cab (and its occupants on the first stop—after which the door windows were closed) was showered with gravel. A subsequent weighbridge check showed that 11-5 cwt. of the load had been lost during the four stops. There was no opportunity of making good the lost load, so the hill-climb and brake-fade tests had to be made at nearly 15 cwt. below recommended g.v.w. The footbrake figures were not matched by the handbrake, due to the lever being far too short to give good leverage and being too close to the driving-seat cushion. If it were possible to move the lever pivot farther back, relative to the engine cowl, and about 2 in. over to the left a longer lever which would be easier to reach could be provided, and improved handbrake retardation would result.

Fish Hill, Broadway, was the scene of the gradient tests, which were carried out in an ambient temperature of I5°C. (59°F) The hill is I-25-mile long and has an average gradient of 1 in 14-2, and before making the climb the engine-coolant temperature was recorded as 80°C. (176°F.). Good time was made during the ascent, and it took 6 min. 40 sec. to reach the top of the hill, at which point the coolant temperature was rechecked and found to be 84°C. (183°F.), which is a reasonable enough rise in view of the steepness of the climb and the speed at which it was made.

Second gear, the lowest ratio used, was engaged for a total time of 5 min. 12 sec., during the course of which period the road speed never fell below 14 m.p.h„ and no exhaust smoking was noted. This shows the FG 5-tonner

B34

to have a good gradient performance and the 5-1-litre engine to be adequately cooled. There is no doubt that, in very hot weather, the cab can get uncomfortably warm because the unit tends to run at a fairly high temperature under normal conditions.

For the fade-resistance test I coasted the vehicle down Fish Hill in neutral, using the footbrake to keep the speed down to a maximum of 20 m.p.h., and. this descent lasted 4 min. 15 see. At the bottom of the hill, a " crash " stop was made from 20 m.p.h. and this produced a Tapley-meter reading of 65 per cent, showing that there had been a reduction in maximum efficienty of 0-3g, which is very reasonable in view of the severity of this test. The pedal effort required had not risen appreciably, and there was only slight smoking from the brakes at front and rear.

The overall braking performance of this model is very commendable, and credit can be shared between the use of Lockheed two-leading-shoe brakes at both axles and Ferodo AM2 linings, this friction material not being commonly used on B.M.C. commercial vehicles. In view excellence of the system. I imagined that the braking front-to-rear would be in the recion of 53 per cent. ctually it has been designed with 45 per cent on the brakes, so the general absence of rear-wheel locking nmendable.

er the gross vehicle weight had been brought back to iginal figure of 8 tons 3-5 cwt. (with two people in the gradient restart tests were carried out on a short ' slope inside the B.M.C. Longbridge factory grounds. handbrake was powerful enough to hold the vehicle facing up and down this gradient, although its effec:ss was obviously greater when the vehicle was facing would have expected the reverse to apply in view of wo-leading-shoe brakes at the rear), and easy part:le restarts were made in bottom and reverse gears. I utempt a restart in second gear, but not even by ng the clutch fiercely could a get-away be made. od acceleration times were recorded from a standing and in top gear from 10 m.p.h. upwards, showing that 5-tonner is a lively vehicle with a good top-gear rmance. Speeds in the gears were recorded as 7.5, .8 and 46 m.p.h., showing a useful spread of ratios. fact that 30 m.p.h. cannot be reached in third gear is ltle significance so far as overtaking other traffic is :rned, as the top-gear acceleration between 30 and p.h. is entirely adequate for such purposes. fen sets of fuel-consumption figures were taken, four carrying the full load and three unladen. Although inladen economy was quite good, the laden figures at least 10 per cent heavier than I would have eted from a vehicle running at this weight. The C. 5.1-litre engine is not normally unduly thirsty, and 1 that some of the trouble may lie in the fact that, ugh the 5.85-to-1 axle ratio is fairly normal for a 1-engined 5-ton vehicle, the effective gearing compared 5-tonners on 20-in, wheels is made lower by the use 7-in. equipment. Whilst the slight gearing reduction this gives is of benefit so far as town working is con the higher rear-axle ratio would be better for stars who wish to use this vehicle on medium-distance ige and delivery work with few stops per mile.

!spite the simplicity of the FG K100's suspension the :le rides well both laden and unladen, and at no time feel the need for dampers either at front or rear. The iner cornered very well, with remarkably little roll. steering was pleasant, with a useful amount of castor 1 speeds and, when laden, a pleasantly firm feel which r really became too heavy at walking pace. The box is by no means difficult to use, although the unit le test vehicle was a bit stiff and the lever was a little far to the rear for my liking. I have already comted on the excellence of the brakes, but it should be ted out that the pedal effort reauired for even normal .dation is a little on the high side by present-day Jards.

enerally, the vehicle is enjoyable to drive despite a t peculiar driving position spoilt by the steering column g on the long side, with the result that the steering el is set rather high in relation to the pedals and windm. This means the seat has to be set fairly high (it is stable longitudinally and vertically), so bringing the H.'s eyes above the top of the windscreen.

rhilst this is no particular disadvantage when travelling g a level stretch of road, it does mean that the driver ally has to crouch down in order to see road conditions ie bottom of a hill. Furthermore, a driver would have culty seeing street names, shop signs and so forth if e are above the level of the cab roof. Really, therefore, screen line should be higher.

wet weather the windscreen is not as useful as it might secause the wipers, pivoted from the upper screen rail, ep inwards without meeting, as if they were aveiding a .ral screen pillar. This means there is a vertical, central ion of the screen at least two inches wide which never

gets wiped. I hope this will be changed soon. Personally, 1 did not find the two lower corner windows, which distinguish this cab, any use, but I do know that some drivers find them an advantage, though in wet, muddy weather these probably soon become opaque.

The cab is fairly comfortable, despite being a little cramped for width and having the wide engine cowl very close to the clutch pedal. Considering the cowl is so close to the seats, the amount of engine noise penetrating the cab

is not at all bad, but ventilation is poor. If it is felt that the kerb-sighting cornerwindows are not going to be of much use, these can be replaced by steel panels incorporating ventilation flaps which would undoubtedly help to cod the cab interior, particularly around the floor.

There are vents in the front bulkhead, but on this 5-ton model air coming through these passes through the radiator block first, so it is quite hot! Heating and demisting units can bc supplied at extra cost to fit over these vents, and as these will heat air already warmed by the radiator their effectiveness should not be difficult to imagine. A single unit on the driving side can be specified, but in this case it demists only the driver's side of the windscreen; for full demisting both heating units are required.

Access to and from the driving seat is undoubtedly good.

and this has timeand fatigue-saving advantages. Stowage space is limited to pockets in each side, ahead of the doors. The large engine cowl would make a very useful tray for papers, order books and so forth if the top pressing were to have a lip around the edge. The side pockets are useful. but small items can easily be forgotten in them. Generally. the finish of the cab is quite fair and the instrument layout ahead of the steering column is good, the only point of criticism being that the flashing-indicator repeater and main-beam warning lights are housed in a little cowl immediately under the steering-wheel boss. This boss effectively hides the lights from the driver's line of sight.

As already said, access to the engine is poor. With the top cowl section removed, the dipstick, oil filler and numbers 5 and 6 injectors can be reached, but the long A.C.silencer, through which the air passes after it has left the main air cleaner, effectively covers the rest of the injectors. There are removable panels in each side of the cowl, each being secured by four Dzus fasteners, but the right-hand panel seems to give access to little more than the cylinder block itself, the fuel-injection pump being too far forward to be reached easily through the aperture. whilst the left-hand panel when removed does give access to the fuel-lift pump and the water drain tap, although the generator is as inaccessible as the injection pump.

In the standard form tested, the B.M.C. FG K100 drop side lorry has a list price of £1,249, the platform-lorry version being £12 10s. less than this. In chassis-cab form the list price is £1,135, whilst chassis-scuttle and chassisf rant end models are priced at £1.031 and £1,099 respectively. In all cases petrol-engined models are £244 cheaper.