STANDARDIZED AXLES FOR MOTOR VEHICLES.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

A Range of Front and Rear Axles to Cover the Needs of All Sizes of Vehicles from 15 cwt. to 5 tons Useful Load Capacity.

ONE OF the •best-known makes of front and rear axles? in America is the, Timken, manufactured by the Timken-Detroit Axle Co., Detroit, Michigan, U.S.A., for which the solo representativesein the British Isles are the Automotive Products Co., 3, BerHers Street, London, W.I.

Axles of this make are becoming popular in this country owing to the satisfactory service which they are giving on numerous vehicles of American manufacture which are marketed here. They • are actually used as standard by some 65 builders of motor vehicles. Their success is probably due to the following fundamental principles :—The employMeld of as few parts as possible ; with ample strength in each; direct lubrication ; oil-tight, dust-proof casings ; and quiet gears. They are manufactured in afactory which is equipped with the latest pattern British-made machinery for the production of the worm gearing, which type of gearing is employed .un all the axles designed for commercial vehicles. The actual gearing utilized is the David Brown F.J. type, which is now employed by many of our bestknown builders, and has been proved by tests conducted at the National Physical Laboratory to be perhaps the most efficient form of worm gearing extant.

Mr. Haldeman Finnic, the assistant to the general managert of the American company, has recently concluded an extended business visit to this country, during which time he was in touch with many of our most prominent manufacturers, and it may I be that. we shall shortly see morel than one well-known maker of commercial vehicles utilizing axles of Timken make.

The following sizes have been standardized :-15 cwt. for express vehicles running on pneumatic tyres, and for vehicles running on solid tyres 20-25 cwt., 11-2 tons, 21-3 tons, 31-4 tons, and 5-6 tons.

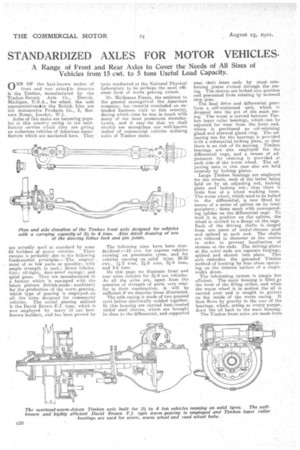

On this page we illustrate front and rear axles suitable for 31-4 ton vehicles. As all the axles are, apart from the question of strength of parts very similar in their construction, it will be sufficient, if we describe these illustrated.

The axle casing is made of two pressed steel halves electrically welded together. In this -housing are carried heat-treated nickel steel sleeves, which are brought in close to the differential, and supported

near tkeir inner ends by stout reinforcing plates riveted through the casing. The sleeves are locked into position and prevented from rotating by screwed stop pins. . The final drive and differential gears form a self-contained unit, which is dropped into the pot of the main easing. The worm is carried between Timken taper roller bearings, which:can he adjusted for wear from the front end, where is positioned an ,oil-retaining gland and screwed gland •ring. The adjusting nut for the bearings is provided with a substantial, locking plate, so that there is no risk of its moving. Timken bearings are also employed for the differential cage, and a means of adjustment for centring is provided at each side of the worm wheel. The adjusting -nuts in this case also are held securely by locking plates. Large Timken bearings are employed for the wheels, each of the latter being held on by an adjusting nut, locking plate and locking nut ; thus there is little fear of a wheel working loose. The worm wheel, which -used to be bolted to the differential, is now fitted by means of a series of splines on its inner periphery ; these mesh with corresponding splines on the differential cage. Tr. hold it in position on the splines, the wheel is riveted to a flange on the cage. Each of the driving shafts is :forged from onepiece of nickel-chrome steel and splined at each end. The shafts are reduced in diameter at the centre in order to prevent localization of stresses at the ends. The driving plates at the outer ends are separate forgings, splined and shrunk into place. This axle embodies the patented Timken method of braking by four shoes operating on the interior surface of a singlewidth drum, The lubricating system is simple but efficient. The main housing is filled lo the level of the filling orifice, and when the worm wheel is in motion the oil is carried over and is caught in gutters on tho inside of the worm easing. It then flews by gravity to the rear of the bearings, which, acting as rotary pumps, draw the oil back to the main housing.

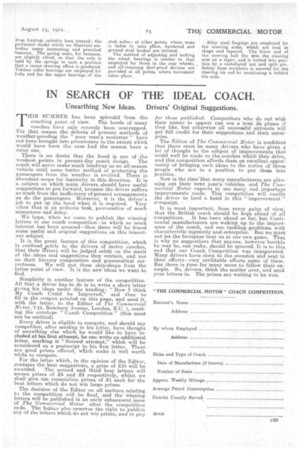

The Timken front axles are made from

drop forgings suitably heat treated; the particular model which we illustrate embodies many interesting and practical features. The spring seats, for instance, are slightly tilted, so that the axle is held by the springs in such a position that a castor steering effect is produced. Timken roller bearings are employed for hubs and for the upper bearings of the

stub axles; at other points where wear is liable to take pace, hardened and ground steel bushes are utilized.

The method of adjusting and locking the wheel bearings is similar to that employed for those in the rear wheels, and nil-retaining dust-proof devices are provided at all points where movement takes place.

Alloy steel forgings are employed for the steering arms, which are oval in shape and tapered. The lower end of the steering ball fits into the steering arm on a taper, and is locked into position by a castellated nut an-d split pin. Safety from accidents is assured for the steering tie rod by positioning it behind the axle.