Trailing-axle Tippers with Alloy Bodies

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

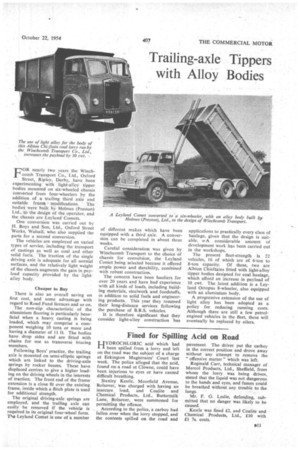

FOR nearly two years the Winchcomb Transport Co., Ltd., Oxford Street, Ripley; Derby, have been experimenting with light-alloy tipper bodies mounted on six-wheeled chassis converted from four-wheelers by the addition of a trailing third axle and suitable framiti modifications. The bodies were built by Holmes (Preston) Ltd., to the design of the operator, and the chassis are Leyland Comets.

One conversion was carried out by H. Boys and Son, Ltd., Oxford Street Works, Walsall, who also supplied the parts for a second conversion.

The vehicles are employed on varied types of service, including the transport of castings as well as coal and other solid fuels. The traction of the single driving axle is adequate for all normal surfaces, and the relatively light weight of the chassis augments the gain in payload capacity provided by the lightalloy body.

Cheaper to Buy There is also an overall saving on first cost, and some advantage with regard to Road Fund licences and so on.

The non-slip characteristic of the aluminium flooring is particularly beneficial when a heavy casting is being loaded, which may comprise a component weighing 10 tons or more and having a diameter of 11 ft. The bodies have drop sides and are fitted with chains for use as transverse bracing members.

Following Boys' practice, the trailing axle is mounted on semi-elliptic springs which are linked to the driving-axle springs by rocker beams. These have displaced centres to give a higher loading on the driving wheels in the interests of traction. The front end of the frame extension is a close fit over the existing frame, inside which a flitch plate is used for additional strength.

The original driving-axle springs are employed, and the trailing axle can easily be removed if the vehicle is required in its original four-wheel form. Tile Leyland Comet is one of a number

of different makes which have been equipped with a third axle. A conversion can be completed in about three weeks.

Careful consideration was given by Winchcomb Transport to the choice of chassis for conversion, the Leyland Cornet being selected because it offered ample power and durability, combined with robust construction.

The concern have been hauliers for over 20 years and have had experience with all kinds of loads, including building materials, steelwork and foodstuffs, in addition to solid fuels and engineering products. This year they resumed their long-distance services following the purchase of B.R.S. vehicles.

It is therefore significant that they consider light-alloy construction has

applications to practically every class of haulage, given that the design is suitable. IPA considerable amount of development work has been carried out in the workshops.

The present fleet-strength is 22 vehicles, 16 of which are of 6-ton to 8-ton capacity. Of these, two are Albion Chieftains fitted with light-alloy tipper bodies designed for coal haulage, which afford an increase in payload of 10 .cwt. The latest addition is a Leyland Octopus 8-wheeler, also equipped with an aluminium body.

A progressive extension of the use of light alloy has been adopted as a policy for reducing running costs. Although there are still a few petrolengined vehicles in the fleet, these will eventually be replaced by oilers.