THE " GIANT-GRIP DRIV E ."

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

The Albaugh-Dover Tractor Plough and Its Unusual Features.

By Henry Sturrney.

THERE ARE CLOSE on 200 different makes of farm tractor produced in the United States, the majority of which are entirely unknown in this country. Several possess original and striking features. Among these may be mentioned the AlbaughDover " square-turn " tractor.

This machine, with its novel features, is a powerful tractor, giving 15 h.p. on the drawbar and 30 h.p. on the belt pulley. The engine is a 4-in. Waukesha, with Dixie magneto. The firm's own method of vaporizing heavy fuel is incorporated. It has no change gear, having one speed only in either direction, but then it has no gears at all, save the driving pinions and gear rings on the, wheels. It works equally well in either direction, is steered by the engine or by a steering wheel.

Whilst Primarily designed as a self-contained meter plough or cultivator, it works equally well as a tractor when reversed. It has no diffetrential, yet drives both wheels. At the same time, either wheel may be driven independently of the other in either direction simultaneously, so that, with one wheel driven forward and the other backward, it swings around on its own axis.

Thus it wastes no space on headlands, and turns, With its plough lifted, in even less space than that e42

required by horses, and, as a result, it can work right up into the corners of the smallest or most irregularly-shaped field, and can cut furrows at absolutely right angles with each other, with dead square, sharp corners.

When used as a self-contained motor plough or cultivator, the two 62-in. by 12-in, driving wheels go first, and the whole control, both of driving and steering, is done by them, the small castor wheel trailing behind.

The machine may be turned about with the small wheel in front and steering, or used as a tractor in the ordinary way.

When ploughing, the work of steering can be done by the engine. No hard, physical effort on the part of the driver is required. The engine also does the work of lifting the ploughs, the lifting mechanism being put into operation by a touch of the foot on a pedal provided for the purpose. Lifting the ploughs is possible either with the machine stationary or travelling, it only being necessary to see that the engine is running. It is built up on a strong frame of 5-in, channel steel, with ample cross members, one end being tapered and finished off with a circular end piece. The steering wheel is mounted here, and is carried in bent forks working in a socket., so that it has a castor action, following the drivers when steering is done by them. The driver's seat is carried on a long, curved-spring support, the base of which fits round the base of the steering 'post. When. the direction of working is altered, this is simply lifted up and turned round.

Five levers are mounted in 'line with the steering post, and as the driver's seat is the same distance from the steering post in either direction, these levers are equally convenient from whichever direction the machine is being handled. One of these levers actuates a brake, and, of the others, two serve to •adjust

the •ploughs for depth of ploughing ; the other two . control the driving and engine-steering operations. The engine is mounted longitudinally in the middle of the frame, with the fl'wheel in front when plough

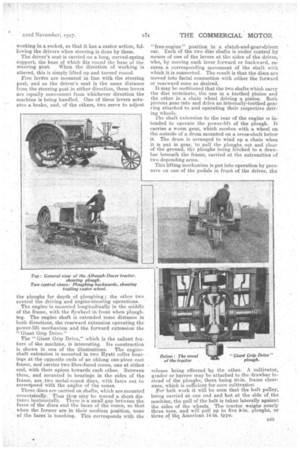

ing. The engine shaft is extended some distance in both directions, the rearward extension operating the power-lift mechanism and the forward • extension the "Giant Grip Drive." • The "Giant Grip Drive," which is the salient fea ture of the machine, is interesting. Its construction

is shown in one of the illustrations. The engineshaft extension is mounted in two Hyatt roller bear

ings at the opposite ends of an oblong one-piece cast frame, and carries two fibre-faced cones, one at either end, with their apices towards each other. Between them, and mounted in bearings in the sides of the

frame, are two metal-coned discs, with faces cut to correspond -with the angles of the cones.

These discs are carried on shafts, which are mounted

eccentsically. Thus they m'hy be moved a short distance horizontally. There is a small gap between the faces of the discs and the faces of the cones, so that when the former are in their medium position, none of the faces is touching. This corresponds with the free-engine" position in a clutch-and-geartdriven car. Each of the two disc shafts is under control by means of one of the levers at the sides of the driver, who, by moving each lever forward or backward, secures a corresponding movement of the shaft with which it is connected. The result is that the discs are moved into facial connection with either the forward or rearward cone as desired.

It may be mentioned that the two shafts which carry the disc terminate, the one in a toothed pinion and the other in a chain wheel driving a pinion. Both pinions gear into and drive an internally-toothed gear ring attached to and operating their respective driving wheels.

The shaft extension to the rear of the engine is in. tended to operate the power-lift of the plough. It. carries a worm gear, which meshes with a wheel on the outside of a drum mounted on a cross-shaft below it. The drum is arranged to wind up a chain when it is put in gear, to pull the ploughs out and clear of the ground, the ploughs being hitched to a drawbar beneath the frame, carried at the extremities of

two. depending arms. . .

• This lifting.mechunism is put into operation by pressure on one of the pedals in front of the driver, the release being effected 'by the other. A cultivator, grader or harrow may be attached to the drawbar instead of the ploughs; there being. 30-in. frame clearance, which is sufficient for corn cultivation.

belt work it will be seen that the belt pulley, being carried -at one end and hot at the side of the machine, the pull of the belt is taken laterally against the sides of the wheels. The tractor weighs nearly three tons, and will pull up to five 9-in, ploughs, or three of the. American 14-in. type.