THE UPKEEP OF STEAM WAGONS.

Page 12

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

No. 1. Points to Remember When Purchasing a New or Second-hand Machine.

THE CHIEF consideration in the commercial use

of steam motor wagons is to.keep the vehicles constantly in use. The bugbear of every user a breakdown, especially if it occurs when delivering a load, and every means should be strenuously ex

erted to avoid such an occurrence. What worse misfortune could befall a wagon than to break down with, say., a load of meat which should be delivered at the market in time for the day's sale? This is not only an inconvenience to the haulage contractor, but also a drawback to trade.

This reliability must be, achieved with a minimum of expenditure if commercial success is to be obtained. Consequently, the wagon must be of sound design and construction ; nothing must be left dependent upon the skill of the driver to keep it in working order except by ordinary care alifj use. Another point to be considered is that the factor of safety of this class of machine is very low, for the wagon must be made as light as possible in order that the minimum of power is ex'pended in moving dead load, and also to meet the legal requirements when carrying a full load.

General Wear and Tear. •

Owing to the speed at which these vehicles travel, and the nature of the roads which have at times to he traversed, 'very heavy stresses are often imposed -upon certain parts of the vehicles, due to the vibrations set up. They have, therefore, to be constructed of the finest materials and with the highest grade of workmanship. The engine has often to work, at a very high speed of revolutions (as high as 900 revs. per minute on some three-ton rubber-tyred wagons).

If a stationary engine is required to run at such a high speed, although it is working on the-fixed bed which is regarded as affording the ideal condition, it is invariably fitted with forced lubrication, is totally enclosed, and perfectly balanced. It would also be constantly under the " eye " and " ear" of the attendant engineer who could detect instantly if the engine was not working " sweetly." These conditions are impossible to obtain in any design of steam wagon; consequently, it is most important that the working parts should always be kept properly adjusted or the engine will soon "knock itself to bits," and require constant renewal of bushes, pins, etc. It is also most important that all parts are properly locked to prevent slackening ; the dropping of a eplit pin will -sometimes lead to a wrecked engine. All bolts should he fitted with lock-nuts, castle-nuts being the best type to use. Washers with split pins alone should never be used, for the pins will wear through and eventually shear off, leaving the washer free to drop off.

Unskilled Drivers the Rule.

There is one other point which must be considered. A driver of a steam wagon is not always what may be termed a skilled engineer. As a matter of fact, he must have other qualifications which are just as vital to successful driving, namely, a knowledge of routes and the places where the goods hav4 to be delivered, and a knowledge of roads and other things peculiar to driving alone. Sometimes the driver is • a man who was previously a driver of horse-drawn vehicles ; censequently, he has probably no mechanical knowledge except -what be has been taught by the expert driver, sent out by the maker of the wagon to start it on its career. When running a fleet of machines this difficulty is overcome by having a competent engineer in cha•rge, who has had special experience with this class of work.

e31

The object of this series of articles, however, is to guide others whose knowledge is not so expert in the driving, maintenance' and repair of steam motor wagons, pointing out where to expect trouble and either to prevent it, or, if defects do occur, how to overcome them.

Points in Choosing a Steam Wagon.

Perhaps it will not be out of place to give a 'few hints upon the mechanical points which should be considered when purchasing a steam motor wagon.

Obviously these will depend to.a great extent upon whether the wagon is new or se-Cond-hand. With a, second-hand wagon this is of even greater importance, because a new one-is _purchased upon the understanding that it is in perfect order, and any defect which develops will be put right by the maker.

Dealing first with a new wagon,one of the most important factors is fuel and water consumption. The cost of fuel is a vital item in the running expenses, and is also one of the "variables," i.e., any excess means money lost and all economy is a direct. gain. The water consumption, although not a serious item of expenditure, is, nevertheless, most important, as it is the chief governing factor of the fuel consumption; it is also the factor which determines the radius of action of the vehicle. A road trial is the only means of ascertaining these consumptions, and it is advisable, in all cases, to have such a test witnessed by a, competent engineer unless the maker gives a guarantee. The :consumptions will, to a, certain extent, depend upon the condition of the roads over which the trial is run, being heavier if the roads are wet or in a bad state.

Road Test Necesary When Buying.

To obtain reliable figures, the road trial should be as long as possible : 50 miles is a suitable distance to give a fair idea of the capabilities of the engine. The trial should start and finish at the same place, then the effect_of all the hills will be practically •

neutralized. When measuring the water consumption, the level of the water in the boiler must be taken into account., and -should be made the same at the finish as it was at the start of the trial. The total amount consumed is then the amount drawr from the tank. The wagon must be at the same level, when measuring these amounts. The state of the fire in the boiler should be the same at the finish as at the start to give a, true figure for the coal consumption. The best plan is to start with a good fire which has just been replenished, and, if the fire is low, at the finish, restoke it to its original Condition, including the fuel so used in the total net amount. It is impossible to give exact figures of what the fuel and .water consumptions shouldbe, but assuming that the trial takes place in dry weather, and that the route traversed is of the ordinary class of road, the following figures may be taken as a fair average :— The above figures are for engines using saturated steam. If the boiler is fitted with a superheater of efficient type, the fuel consumption ought to be about

30 per cent, less and the water consumption about 25 per cent. less.

The radius of action of the vehicle is governed by the size of the water, tank, the usual sizes being 130 gallons for a three-ton wagon and 150 gallons for a five-ton wagon. The figures for a wagon fully loaded will then be as follow:—

With regard to the power uf the wagon the easiest way to ascertain if this is ,sufficient is to test its hillclimbing capability. In slow gear the wagon with full 'load ought to go:up any bill found on the roads. The steepest gradient is usually taken as 1 in 6, 1 ut this is only occasionally met! with in this country. In fast gear, the wagon ought to .go up a gradient of 1 in 25 without using the auxiliary, or double high pressure, steam valve, and up 1 in 20 by using i the latter. But, in general. practice, this shouldZionly be used for short periods to help.get out of an awkward place or to get up a very short, sharp rise. The power of a wagon must not be judged by the size of the cylinders alone for there are other factors which must be taken into account, viz., the working steam pressure, the ratio of steam expansion in the cylinders _the ratio of the gearing, and the size of the wheels, also the capacity of the boiler to produce steam.

Daring the road trial the following points should also be observed :—

(a) Will the boiler keep up a constant supply of steam at the full working pressure? This will depend to a certain extent upon the exhaust nozzle being properly adjusted.

(b) The engine parts should run " sweetly" and no knock should be observable in any part, especially the connecting rods, eccentric rods, and the link motion. ('e) The crankshaft bearings, connecting rod brasses, back axle bearings, and front wheel hubs should be tested to see whether they get overheated. (d)'The gearing should run quietly without any grinding noise. This will show, whether the gearwheels are. properly cut and in correct mesh. (e) Does the feed pump keep up a constant supply of water to the boiler ? The injector 'should also be tested.

(f) Test the brakes on the steepest hill to see that they will keep the wagon under control.

Another important feature of a wagon is its weight. The legal requirements are as follow:—

Failings in Design.

A common failing with many steam wagons is too much weight on the. back axle. Thisl is often caused by putting the back axle too far forward, in order to obtain a short wheelbase so that sharp turns can be

accomplished. It is also sometimes done to relieve the front axle of some weight if the steering is too stiff. In the latter 'ease the proper way is to attend to the steerage,worm.geat and the front swivel, for it is quite possible to construct these parts so that a wagon can oe comfortably steered even with the full legal weight of•four ttns on the front wheels.

The back.axle should never be in front of the centre of the body, as shown in Fig. 1, or the extra overhang of the body. behind the axle will cause excessive vibration, with the result Of cracked frames as well as damaging the load if it is of a fragile nature, such as furniture. ..There is a similar effect, of course, even if the body space is correctly placed, if the load is badly distributed towards the rear.

The turning radius of a wagon is goveanad'be the length of the. wheelbase and the lock of the front axle ; this is illustrated in Fig. 1.

The level of the platform above the ground should be as low at possible to-facilitate loading, providing there isesufficient clearance above the wheels to prevent bumping when travelling over rough ground. But. the platform levelashould not Ile lower •tha,n the average loading bay. One maker did • this and his vehicles, were often found unsuitable,for unloading. The ground clearance under !the as.hpan should be aufficient,toTrevent'bumping when passing over small bridges, with large canal:ter or other obstacles ; about 10 ins, is usually sufficient. Theo facility with which renewals can be obtained should also be considered when purchasing a wagon. Even now, some firms do not give this pointlaufficient attention, and, often, when a customer writes for a new part it has to be specially made, thus causing

great inconvenience to the user through the wagon remaining idle until the new part arrives.

Second-hapd Vehicles.

With a second-hand wagon this question of renewals is even of greater importance, for there is a danger of the vehicle being of an obsolete type. It is, therefore, advisable to steer clear of • a vehicle made by some firm which has ceased to exist, no matter how cheap its price.

Most of the foregoing, points relating to new wagons are applicable to second-hand ones, 'but, in addition, a careful examination of the structural condition should be made.

Beginning first with the boiler this should be .thoroughly examined both wider steam and empty. When under steam all joints should be t.perfectly steam tight, also the tubes, especially at the firebox end. See that the manhole and muaole 'covers are tight, and that the smokebox door is airtight.

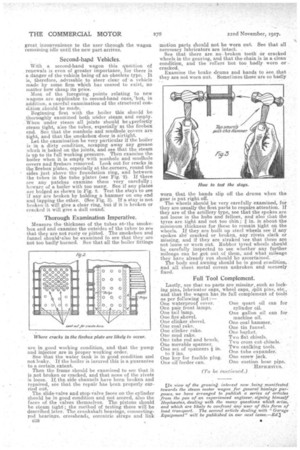

Let the examination be very particular if the boiler is in a dirty condition, scraping away any grease which is baked on the joints, and see that the steam is up to its full working pressure. Then examine the boiler when it is empty with manhole and madhole covers and firebars removed. Look out for cracks in the-firebox plates, especially at the.corners, round the sides just above the foundation ring, and between the tubes in the tube plates (see Fig. .2). If there are any patches examine them very carefully ; br,•wars of a boiler with too many. See if any plates are bulged as shown in Fig. 2. Test the stays to see if any are broken by holding a hammer on one end and tapping the other. (See Fig. 3). If a stay is not broken it will give a clear ring, but if it is broken or cracked it will give a dull sound:

Thorough Examination Imperative.

Measure the thickness of the tubes at,the smokebox end and examine the outsides of the tubes to see that they are not rusty or pitted. The smokebox and funnel should+also be examined to see that they are not too badly' burned. See that all the boiler fittings

are in good working condition, and that the pump and injector are in proper working order.

See that the water tank is in good condition and not leaky. If the boiler is insured this is a guarantee to a certain. extent.

Then the frame should be examined to see that it is hot broken or cracked, and that none of the rivets is loose, if, the, side channels have been broken and repaired, see that the repair has been properly carried out.

The slide-valve and stop-valve faces on the cylinder should be in good condition and not scored, also the faces of. the valves themselves. The pistons should be steam tight ; the method of testing these will be described later. The crankshaft bearings, connectingrod bearings, crossheads, eccentric straps and link o35 motion parts should not be worn out. See that all necessary lubricators are intact. See that there are no broken teeth or cracked wheels in the gearing, and that the chain is in a clean condition, and the rollers hot too badly worn or. cracked.

Examine the brake drums and bands to see that they are not worn out. Sometimes these are so badly worn that the bands slip off the drums when the gear is put right off.

The wheels should be very carefully examined, for they are usually the first parts to require attention. If they are of the artillery type, see that the spokes are not loose in the hubs and felloes, and also that the tyres are tight and not too thin.; i• in. is about the minimum thickness for these to remain tight on the wheels. If they are built up steel wheels see if any spokes a:re cracked or broken, any rivets slack or missing, and if they are straked 'see that these are not loose or worn out. Rubber tyred wheels should be carefully inspected to see whether any further mileage can be got out of them, and what Mileage they have already run should be ascertained. • The body and awning should be in good condition, and all sheet metal covers unbroken and securely fixed.

[In view of the growing interest now being manifested towards the steam motor wagon for general haulage purposes, we have arranged to publish a series of articles from the pen of an experienced engineer, signing himself Hephtesius, dealing with the many questions which arise, and which are likely to confront any user of this form of load transport. The second article dealing with "Garage Equipment" will be published in. our next issue.—Ed.3